Filter-Regulator-Lubricator (FRL)

Instructions

Reed Manufacturing

1425 West 8th Street

Erie, PA 16502 USA

1220-54516

FRL Operation

It is imperative that a lter, regulator, lubricator (FRL) be employed

when running pneumatic tools. The air should be clean, dry, and

lubricated to maximize life and performance of the pneumatic

tool. Maximum pressure for the FRL is 120 psi.

Use Nonuid Oil®Air Lubricant

This product mixes with water and via the Air Lubricator is intro-

duced as a mist in the air stream to provide lubrication. Nonuid

lubricating oil is sold by Reed as UPOIL #97583, 16 ounces.

FIGURE 3

2 of 2

Operation

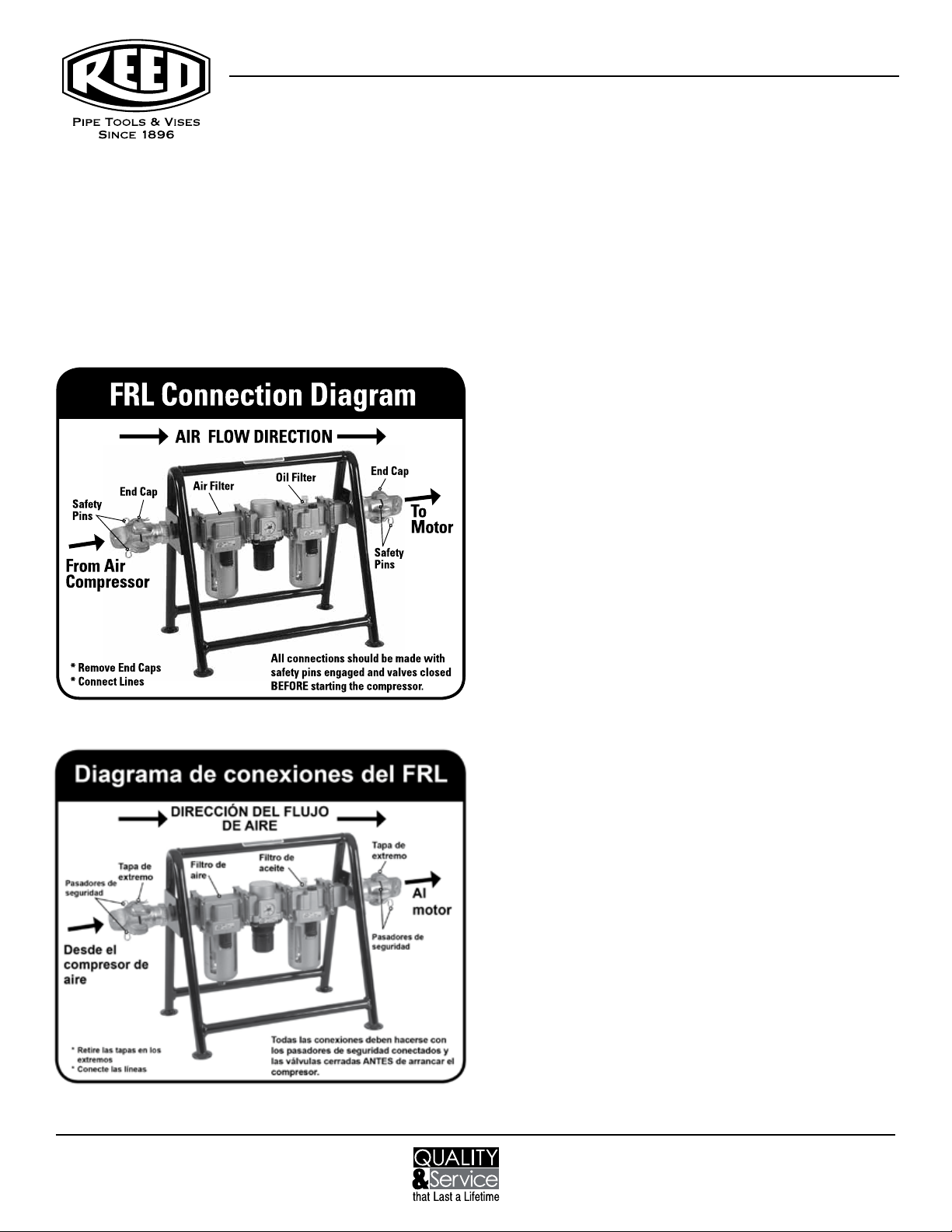

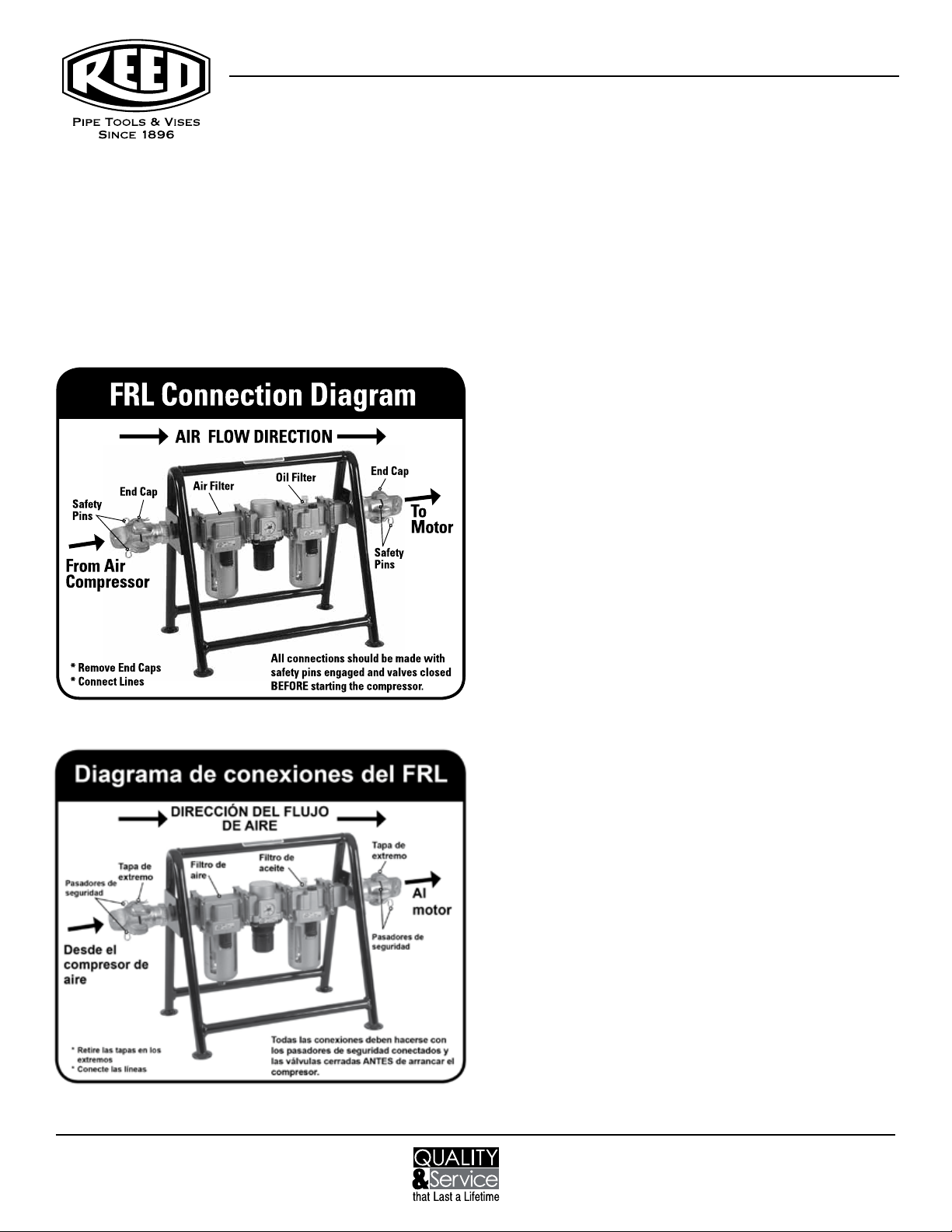

Connect the airlines to the FRL. The direction of the air ow is in-

dicated by arrows on the top of the FRL. With the pneumatic tool

connected and in the o position, turn on the supply air to the

FRL. Check the level of uids in the clear bowls on the bottom of

the Air Filter and Air Lubricator.

If the air lter bowl contains water, drain the bowl by pressing and

holding the small button on the bottom of the bowl until the water

is completely drained. Observe the maximum water level line on

the metal protective shield of the bowl. Water can be drained with

either the air supply on or o.

The oil level in the air lubricator must be maintained for proper

lubrication of the pneumatic tool. The minimum and maximum

oil levels are indicated on the metal protective shield of the oiler

bowl. To add oil, remove the black oil plug at the top of the oiler

with a ¼” hex wrench, add oil and replace the plug. USE NON-

FLUID OIL. Oil can be added with either the air supply on or o.

The air pressure is indicated on the dial gauge on the front of

the Pressure Regulator. To adjust the air pressures, pull the large

black knob below the gauge down to the unlocked position.

When unlocked, an orange band can be observed on the top of

the knob (Figure 1). Turn the knob clockwise to increase the pres-

sure. When the desired pressure is reach push the knob up to the

locked position. (The orange band is no longer visible.)

The amount of lubricant supplied to the pneumatic tool is regu-

lated by the number of drops of oil per minute and is observed

through the site window of the oil adjusting valve knob at the

top of the Air Lubricator (Figure 1). Check the specic pneumatic

tool manual for lubrication requirements. Numbers on the scale

of the adjusting knob do not indicate drop amounts. Turn the

adjusting knob clockwise to the o position then turn that same

knob counter clockwise until the indication mark is on 4 or 5. This

is a good starting point. The tool must be running to adjust the

number of drops per minute of lubricant. With the pneumatic tool

running, turn the knob to adjust to the required number of drops.

Counterclockwise will increase the number of drops.

The FLR bowls need periodic inspection during the use of the

pneumatic tool.

Phone: 800-666-3691 or +1-814-452-3691

www.reedmfgco.com