Table of contents

FlexiMova®mm - Design and Installation

3 of 80

1 Manufacturer ....................................................... 6

1.1 Customer service centres ............................................................. 6

1.2 Request for technical assistance ...................................................... 6

2 Important information ........................................ 7

2.1 Manual ID ..................................................................................... 7

2.2 Information regarding the manual .................................................. 7

2.3 Intended audience ....................................................................... 8

2.4 Authorized operators................................................................... 8

2.5 Manual conventions .................................................................... 9

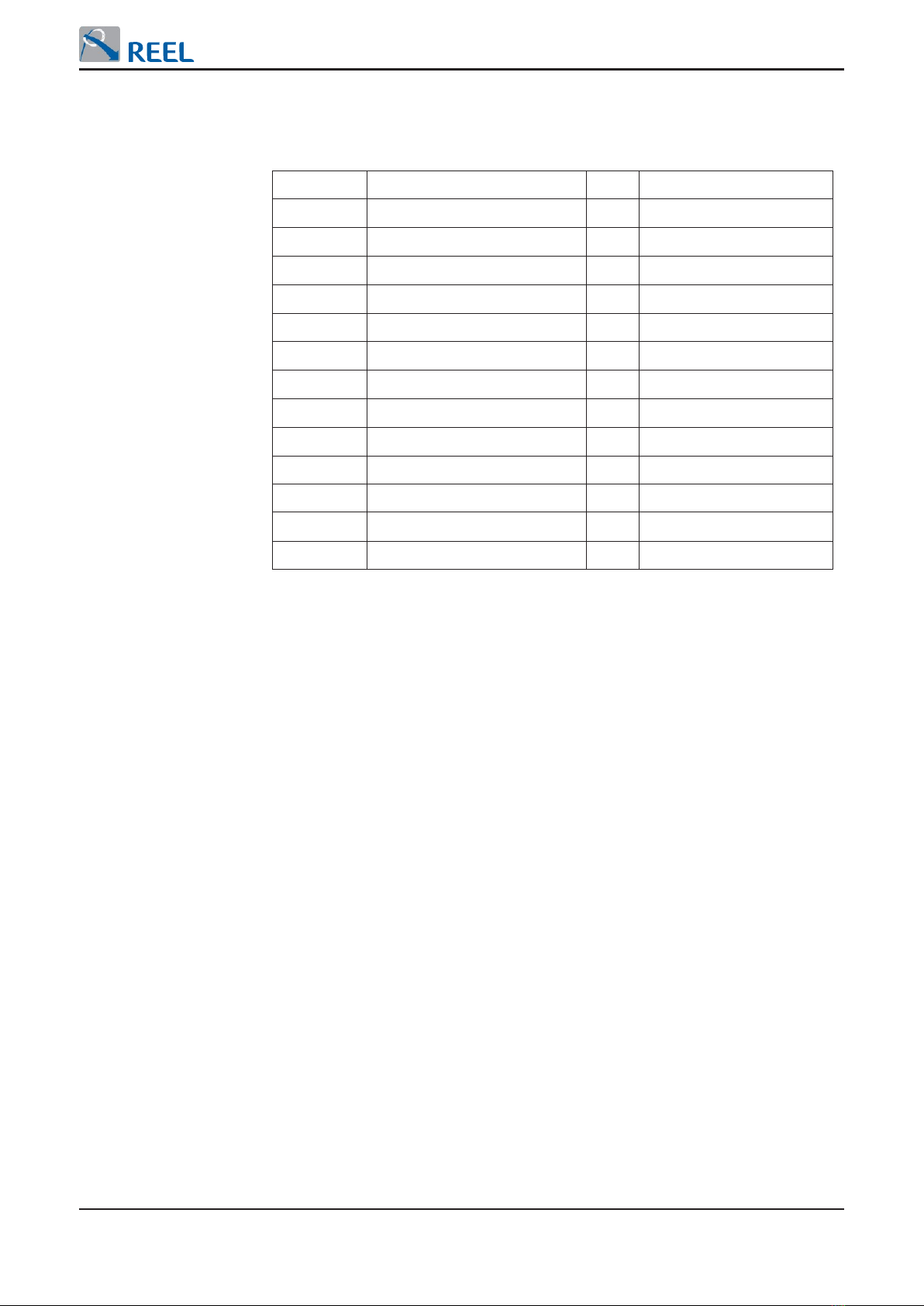

2.6 Main abbreviations ............................................................................ 10

2.7 All rights reserved ......................................................................................... 10

2.8 Warranty ............................................................................................. 10

3Product ID .................................................................12

3.1 Designation ........................................................................................ 12

3.2 Sizes – Models................................................................................................ 12

4Conformity ...............................................................13

4.1 Normative references cited in this EU Declaration of Conformity . 13

4.2 Normative references relating to the STO safety function ............. 13

4.3 Data and CE marking plate ............................................................... 13

5Product specifications..............................................14

5.1 Description.......................................................................................... 14

5.1.1 Ingress protection rating and requirements .................................... 15

5.2 Technical data .................................................................................... 15

5.2.1 Product efficiency............................................................................... 19

5.3

Denomination of components of the FlexiMova® mm size A ....20

5.4 Denomination of components of the FlexiMova® mm size B........ 21

5.5 Denomination of components of the FlexiMova® mm size C........ 22

5.6 Denomination of components of the FlexiMova® mm size D ....... 23

5.7 Denomination of components of the FlexiMova® mm size E........ 24

5.8 Description of the graphic keypad (optional).................................. 25

5.9 Converter dimensions, weights and fixings ..................................... 26

5.10 Intended use....................................................................................... 27

5.11 Reasonably foreseeable misuse......................................................... 27

5.12 Residual risks....................................................................................... 28

5.13 Personal protective equipment (PPE) ............................................... 29

5.14 Tools.................................................................................................... 30

5.15 Protective devices............................................................................... 30

5.15.1 Fuses .................................................................................................... 30

5.15.2 Automatic differential thermal-magnetic circuit breaker at line

inlet………………………………………………………………………… 31

5.15.3 Motor PTC protections....................................................................... 31

6Transportation - Storage – Disposal .......................32

6.1 Packaging ........................................................................................... 32

6.2 Transportation.................................................................................... 32

6.3 Storage................................................................................................ 32

6.4 Disposal............................................................................................... 33

7Mounting instructions for the converter ...............

33

7.1 General instructions ........................................................................... 33

7.2 Mounting types .................................................................................. 33

7.2.1 Wall or machine mounted................................................................. 34

7.2.2 Motor mounted....................................................................................35

7.2.3 Direct mounting on REEL SuPremE® motor fitted with traditional

terminalbox by means of mechanical adapter plate ....................... 38

8Electrical connections ..............................................39

8.1 Electromagnetic compatibility .......................................................... 39

8.1.1 Classification....................................................................................... 39

8.1.2 Requirements for network harmonics .............................................. 39