StepperOnline DM556N User manual

Table of contents

Other StepperOnline DC Drive manuals

StepperOnline

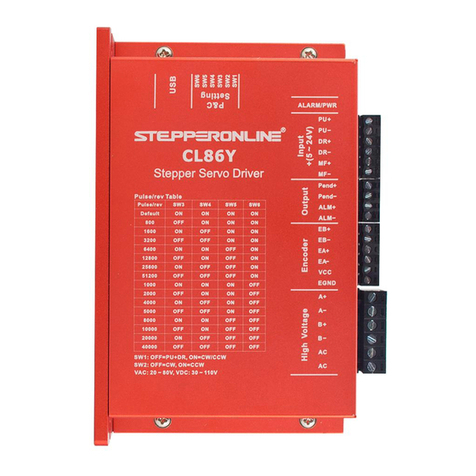

StepperOnline Y Series User manual

StepperOnline

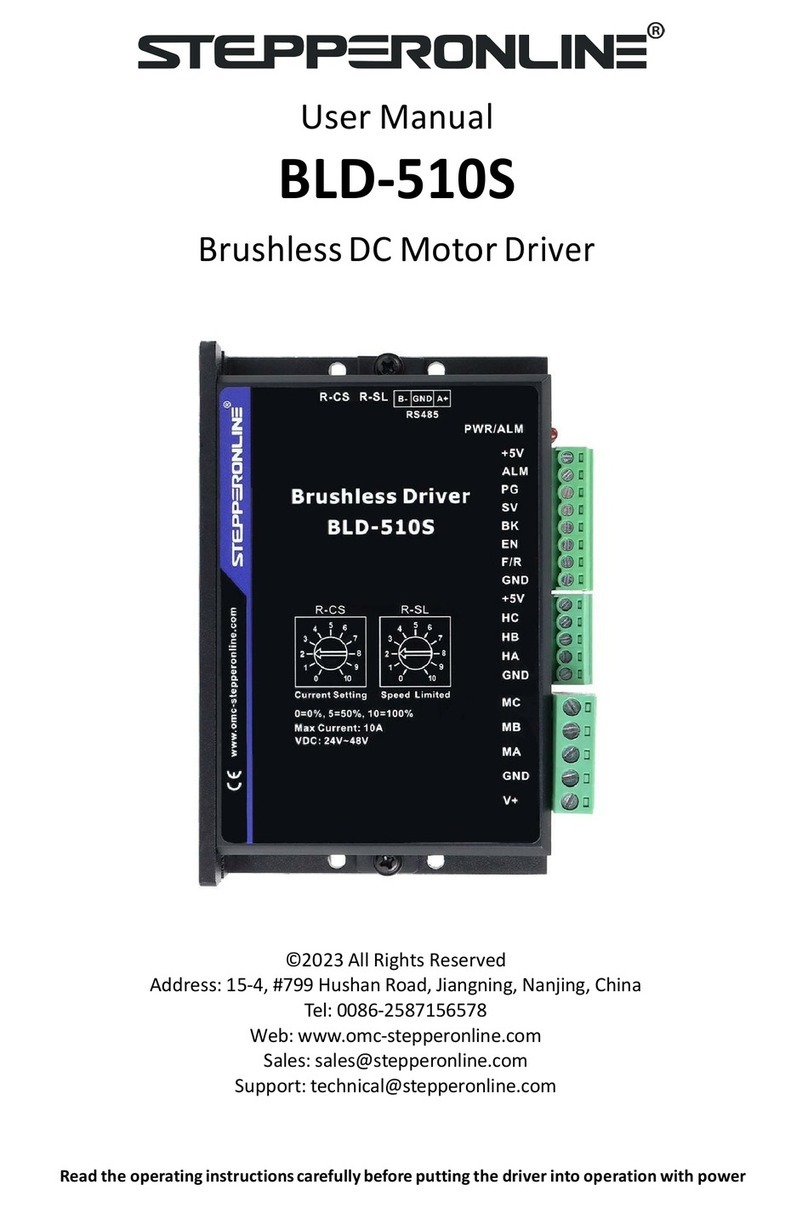

StepperOnline BLD-510S User manual

StepperOnline

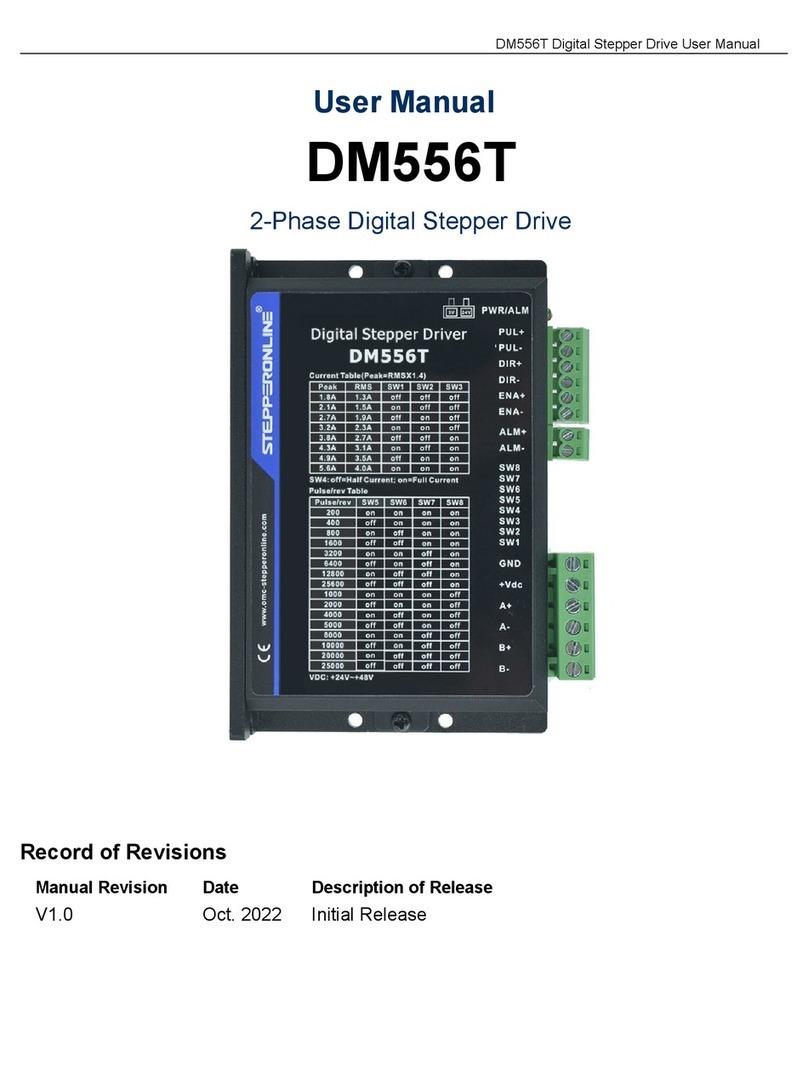

StepperOnline DM556T User manual

StepperOnline

StepperOnline CL57T User manual

StepperOnline

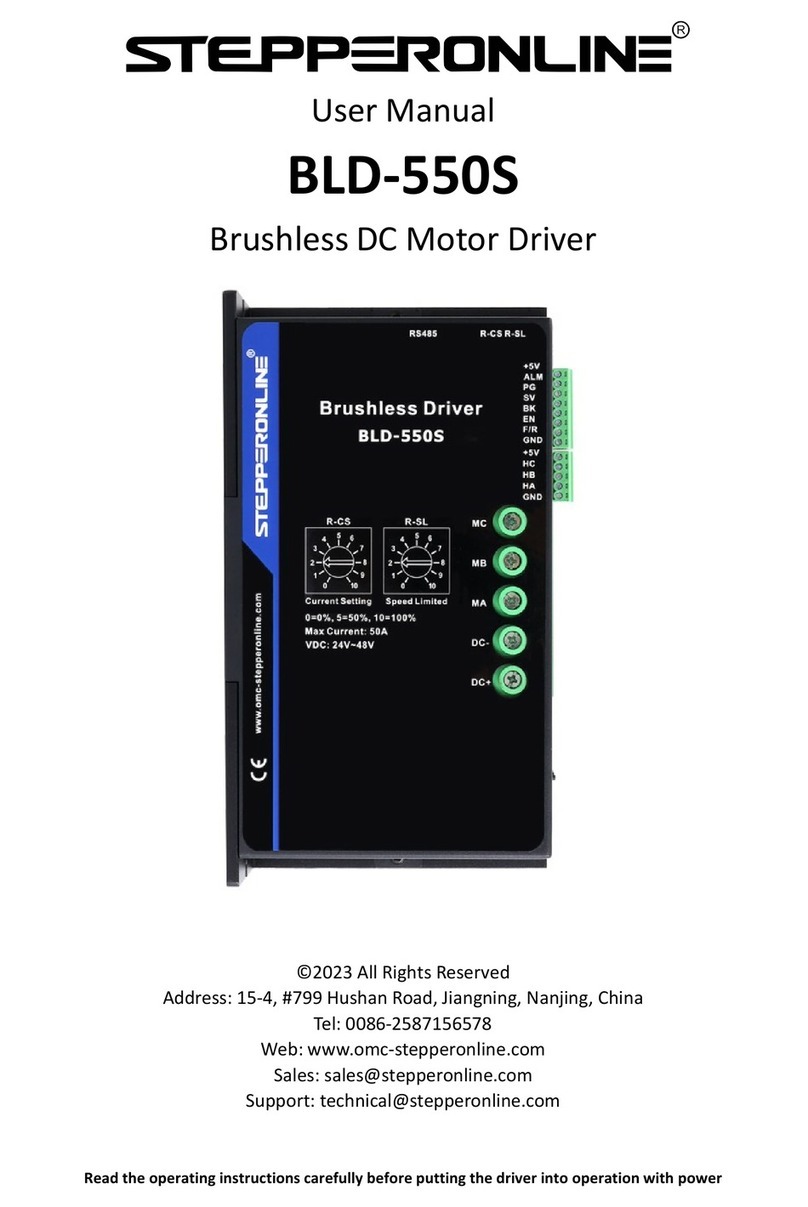

StepperOnline BLD-550S User manual

StepperOnline

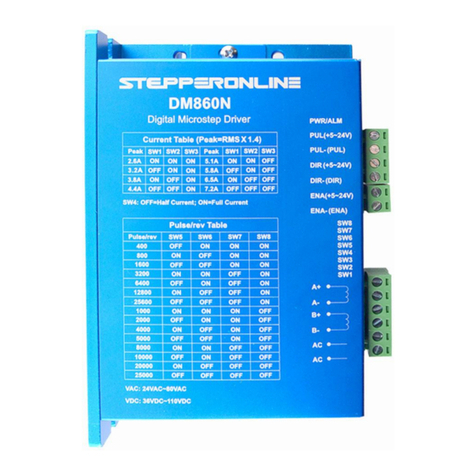

StepperOnline DM860T User manual

StepperOnline

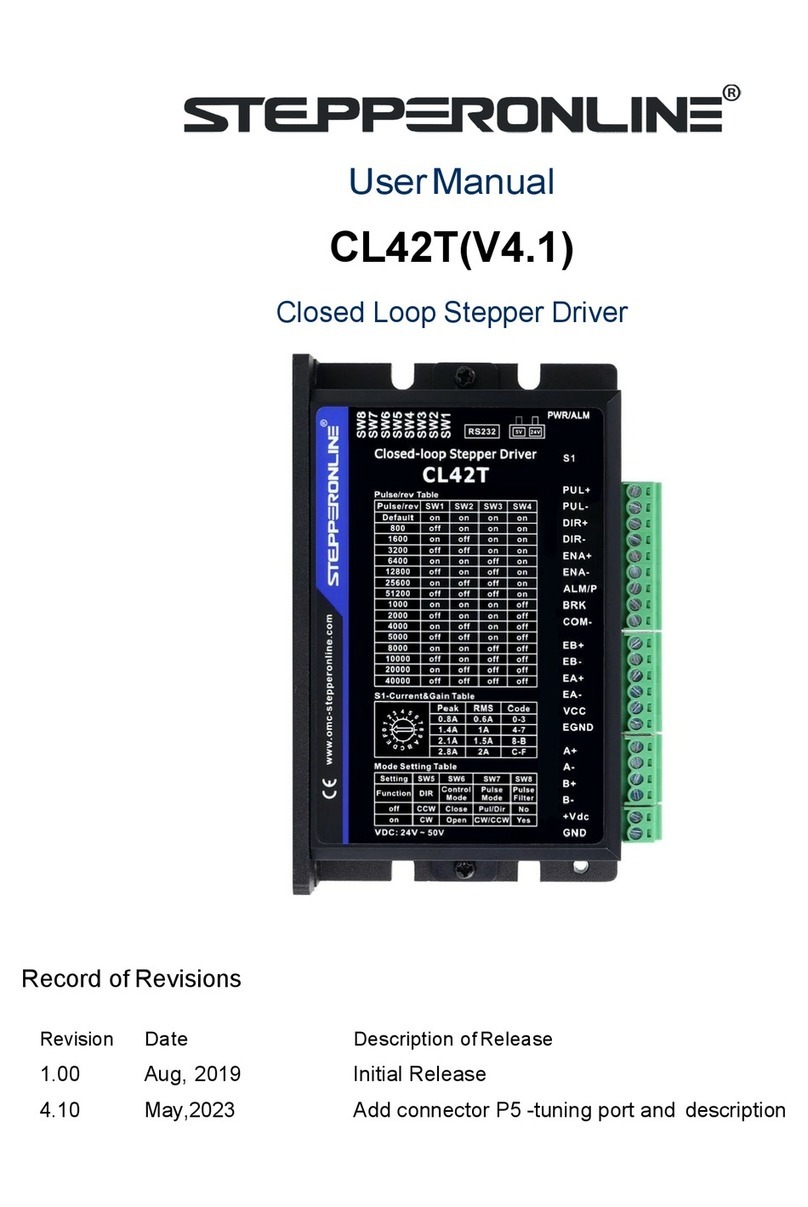

StepperOnline CL42T User manual

StepperOnline

StepperOnline CLRS Series User manual

StepperOnline

StepperOnline DM556T User manual

StepperOnline

StepperOnline DMT556T User manual

Popular DC Drive manuals by other brands

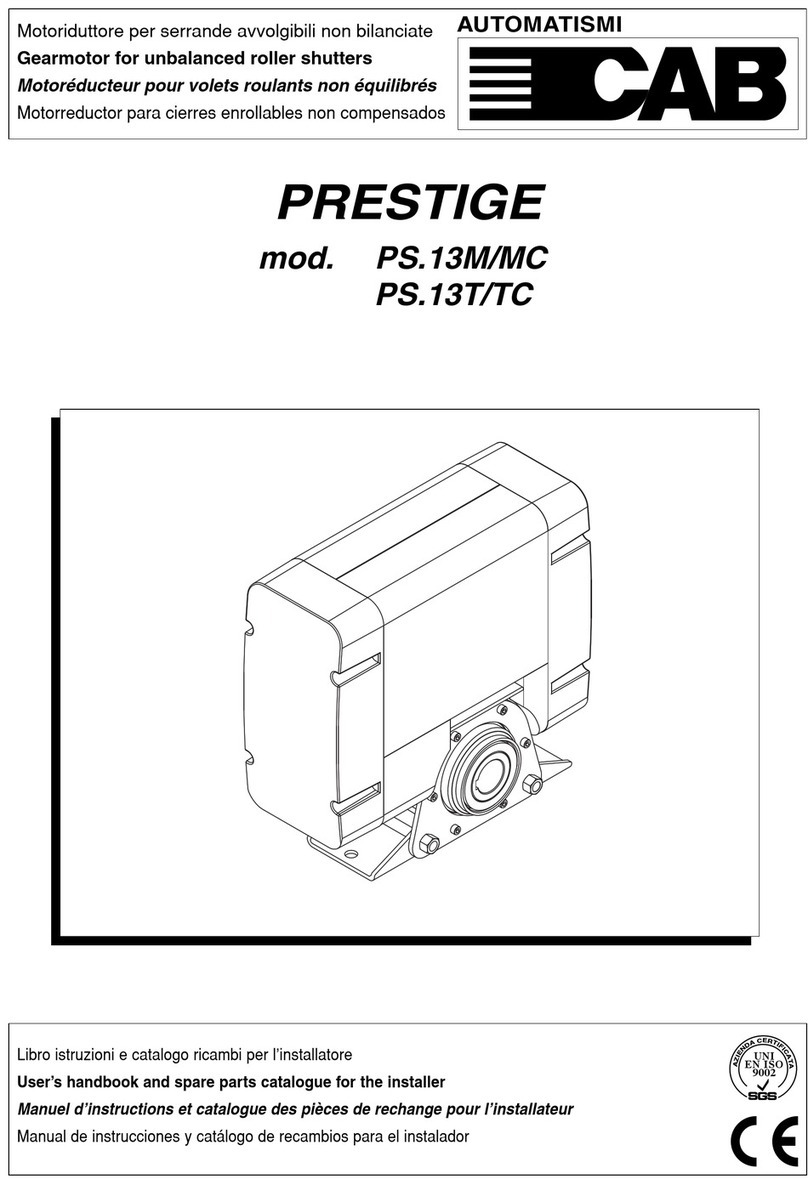

Automatismi CAB

Automatismi CAB PRESTIGE PS.13M User handbook

Mitsubishi Electric

Mitsubishi Electric FR-F740-00023-EC instruction manual

WEG

WEG CFW-11 Series user manual

Technosoft

Technosoft iMOTIONCUBE BX-CAN Technical reference

Kollmorgen

Kollmorgen AKD-x00306 installation manual

Rtelligent

Rtelligent 5R60 user manual

Festo

Festo EMCA-EC-67 CO Series Original instructions

Eaton

Eaton PowerXL DE1 series quick start guide

Peaco Support

Peaco Support FC280 Series user manual

Cole Parmer

Cole Parmer MasterFlex L/S 77200-00 operating manual

Pro-dig

Pro-dig DDT25K instruction manual

Nidec

Nidec RINDCODE NRX Series instruction manual