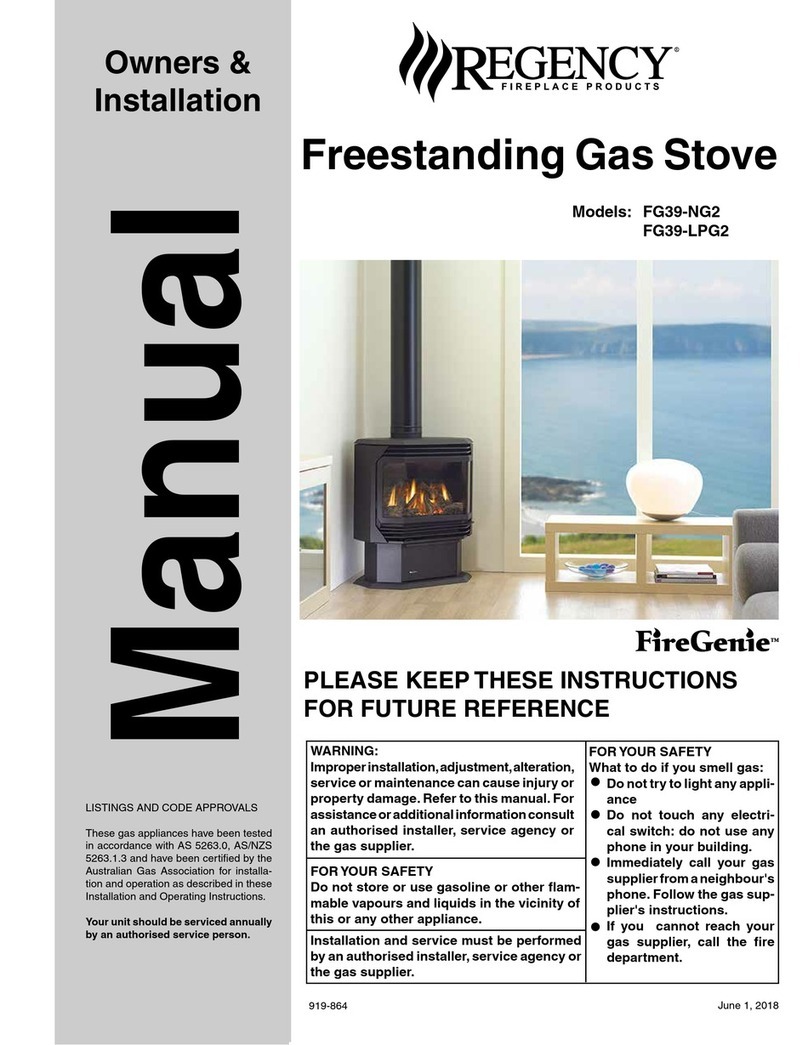

Regency FG39 FireGenie Freestanding Gas Stove 5

IMPORTANT:

SAVE THESE

INSTRUCTIONS

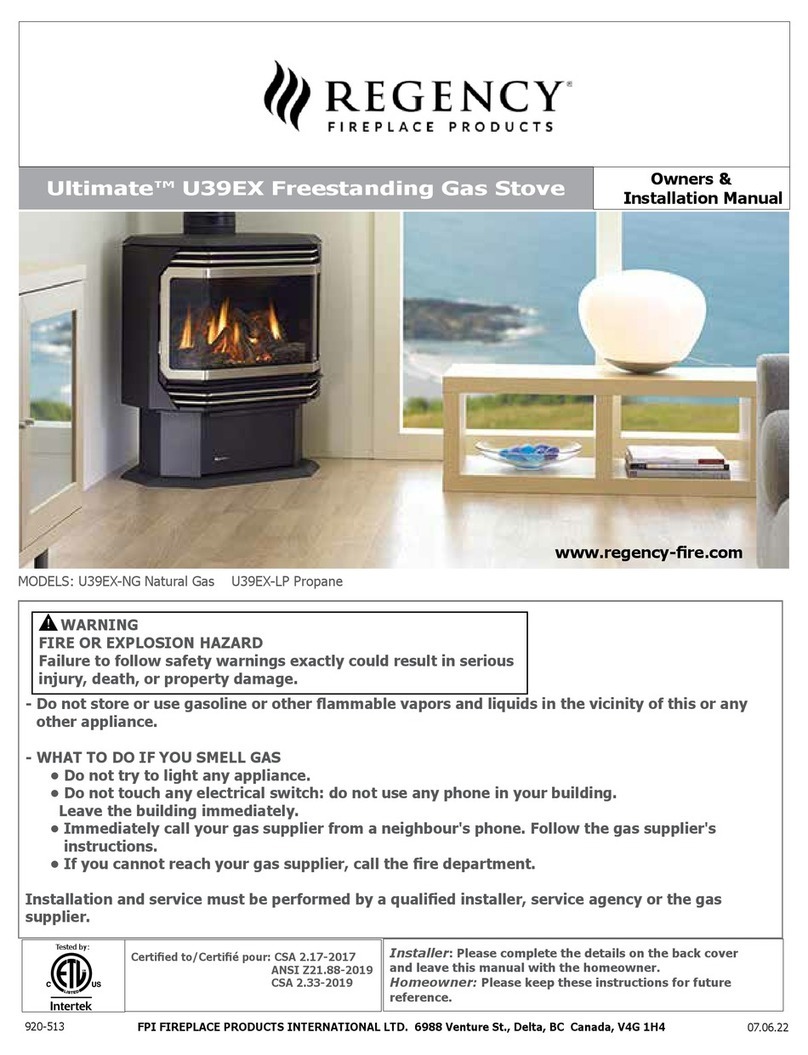

The REGENCY Room Sealed Freestanding Gas

Stove must e installed in accordance AG601

and NZS 5261 and with these instructions.

Carefully read all the instructions in this manual

first. Consult the uilding authority having juris-

diction to determine the need for a permit prior

to starting the installation.

Note: Failure to follow the instructions

could cause a malfunction of the

heater which could result in death,

serious bodily injury, and or prop-

erty damage. Failure to follow

these instructions may also void

your fire insurance and or war-

ranty.

Note: These instructions take prece-

dence over Simpson Dura-Flue in-

structions.

SPECIFICATIONS

Fuels: FG39-NG is approved for use with NG.

FG39-LPG is approved for use with

liquefied petroleum gases (LPG).

Electrical: 240V A.C. system.

Circulation Fan: Varia le speed, 125/75.

Log Sets: Ceramic fi re, 7 per set.

Flue System: Coaxial (6-5/8" outer / 4" inner

liner) rigid flue and termination cap.

BEFORE YOU START

Safe installation and operation of this appliance

requires common sense, however, we are

required y the Canadian Safety Standards

and ANSI Standards to make you aware of the

following:

INSTALLATION

ING, ETC. IT IS IMPERATIVE THAT

THE CONTROL COMPARTMENT,

BURNERS AND CIRCULATING AIR

PASSAGEWAYS OF THE APPLI-

ANCE BE KEPT CLEAN.

DUE TO HIGH TEMPERATURES,

THE APPLIANCE SHOULD BE LO-

CATED OUT OF TRAFFIC AND

AWAY FROM FURNITURE AND

DRAPERIES.

WARNING: FAILURE TO INSTALL

THIS APPLIANCE CORRECTLY

WILL VOID YOUR WARRANTY AND

MAY CAUSE A SERIOUS HOUSE

FIRE.

CHILDREN AND ADULTS SHOULD

BE ALERTED TO THE HAZARDS

OF HIGH SURFACE TEMPERA-

TURES, ESPECIALLY THE FIRE-

PLACE GLASS, AND SHOULD

STAY AWAY TO AVOID BURNS

OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISED WHEN

THEY ARE IN THE SAME ROOM AS

THE APPLIANCE.

CLOTHING OR OTHER FLAMMA-

BLE MATERIAL SHOULD NOT BE

PLACED ON OR NEAR THE APPLI-

ANCE.

INSTALLATION AND REPAIRS

SHOULD BE DONE BY AN AUTHOR-

IZED SERVICE PERSON. THIS AP-

PLIANCE SHOULD BE INSTALLED,

REPAIRED, INSPECTED BEFORE

USE AND AT LEAST ANNUALLY

BY AN AUTHORIZED SERVICE PER-

SON. MORE FREQUENT CLEAN-

ING MAY BE REQUIRED DUE TO

EXCESSIVE LINT FROM CARPET-

page 6. This unit is approved for manufac-

tured home installations, see page 9 for the

required flue arrangements. If installed into

a manufactured home the unit must e

olted down to the floor.

4) This appliance is Listed for edroom instal-

lations when used with a Listed Millivolt

Thermostat. Some areas may have further

requirements, check local codes efore

installation.

5) This appliance is Listed for Alcove installa-

tions, maintain minimum Alcove clearances

as follows, m i n i mum width of 48" (1219mm),

a maximum depth of 36" (914mm), and

minimum ceiling height of 64"(1626mm).

6) We recommend that you plan your installa-

tion on paper using exact measurements

for clearances and floor protection efore

actually installing this appliance. Have an

authorized uilding inspector review your

plans efore installation.

GENERAL SAFETY

INFORMATION

1) The appliance shall e installed in accord-

ance with the manufacturer's installation

instructions,local gas fitting regulations, mu-

nicipal uilding codes, water supply regu-

lations, electrical wiring regulations, with

AS5601-2004 (AGA gas installation code)

NZS 5261 (New Zealand)

2) Installation and repair should be done

ONLY by an authorised person.

3) DO NOT CONNECT TO MASONARY FLUE.

4) This appliance must be connected to

the specified flue and termination cap

to the outside of the building enve-

lope. Never flue to another room or

inside a building. Make sure that the

flue is fitted as per Flueing instruc-

tions.

5) Inspect the flueing system annually for

lockage and any signs of deterioration.

6) Flueing terminals shall not e recessed into

a wall or siding.

7) Any safety glass removed for servicing

must e replaced prior to operating the

appliance.

8) To prevent injury, do not allow anyone who

is unfamiliar with the operation to use the

fireplace.

9) Wear gloves and safety glasses for protec-

tion while doing required maintenance.

1) Provide adequate clearances for servicing,

proper operation and around the air open-

ings into the com ustion cham er.

2) The appliance may e installed on a flat,

solid, continuous surface (e.g. wood, met-

al, concrete). This may e the floor, or it can

e raised up on a platform to enhance its

visual impact. The appliance may e in-

stalled on carpeting, tile, wood flooring or

other com usti le material, ecause the

appliance's metal pedestal ase extends

the full width and depth of the appliance.

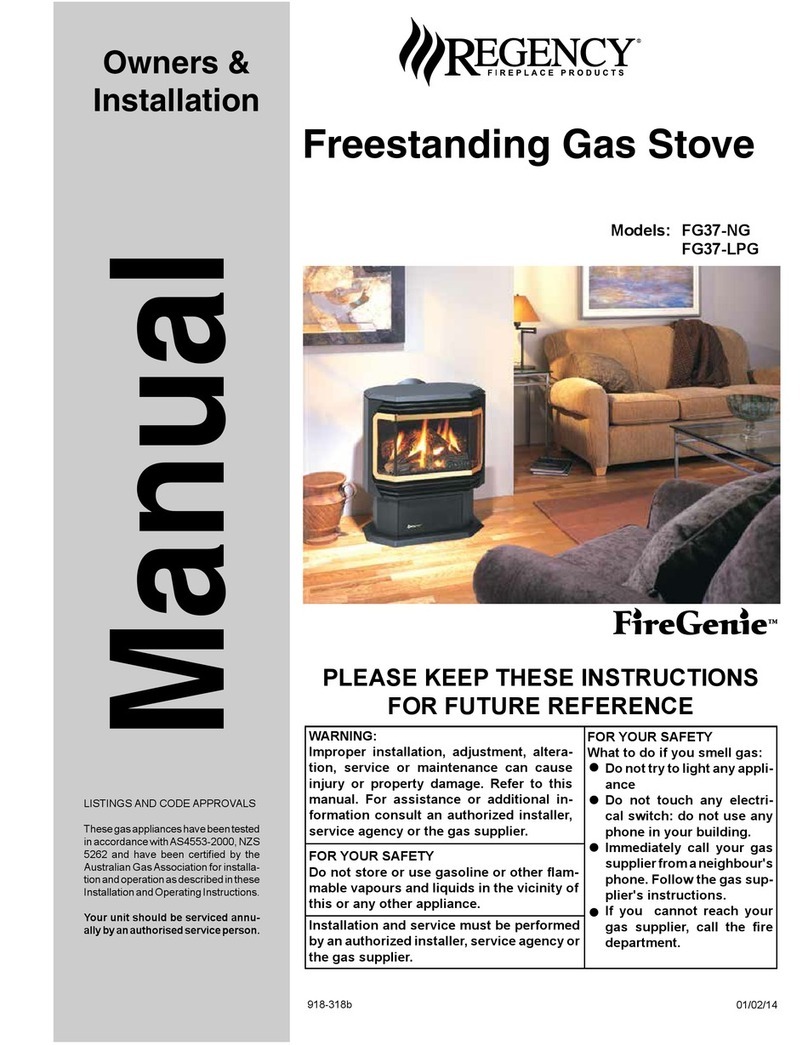

The Regency Room Sealed Freestanding

Gas Stove can e installed in a wide variety

of ways and will fit nearly any room layout.

It may e installed in a recessed position,

framed out into the room, or across a cor-

ner.

3) The Regency Room Sealed Freestanding

Gas Stove is approved for alcove installa-

tions, which meet the clearances listed on