8U37-1 Regency®ULTIMATE Rear Vent Direct Vent Freestanding Gas Stove

INSTALLATION

IMPORTANT MESSAGE

SAVE THESE

INSTRUCTIONS

TheULTIMATERearVentDirectVentFreestanding

GasStovemustbeinstalledinaccordancewiththese

instructions.Carefullyreadalltheinstructionsinthis

manual first. Consult the building authority having

jurisdiction to determine the need for a permit prior

to starting the installation.

Note: Failure to follow the instructions could

cause a malfunction of the heater which

could result in death, serious bodily in-

jury,and/orproperty damage. Failure to

follow these instructions may also void

your fire insurance and/or warranty.

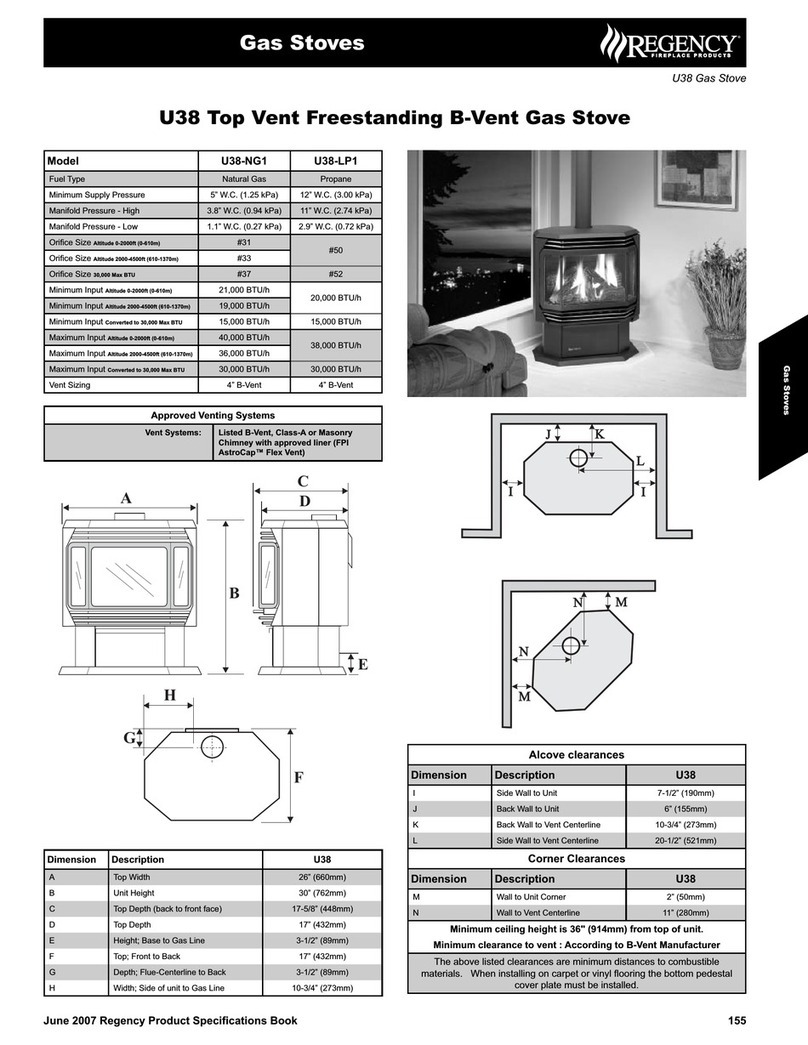

SPECIFICATIONS

Fuels: U37-NG1isapprovedforusewithnatural

gas.

U37-LP1isapprovedforusewithliquefied

petroleum gases (propane).

Electrical: 120 V A.C. system.

Circulation Fan: Variable speed, 125/75.

Log Sets: Ceramic fibre, 7 per set.

Vent System:

Axial (6-5/8" outer / 4" inner liner) rigid

flue and Riser Vent Terminal.

GENERAL SAFETY

INFORMATION

1) The appliance installation must conform with

local Canadian Electrical Code.

2) The appliance when installed, must be electri-

callygroundedinaccordance with local codes,

orintheabsenceoflocalcodeswiththecurrent

NationalElectricalCode,ANSI/NFPA70orCSA

C22.1 Canadian Electrical Code.

3) The applianceshouldbeinspectedforshipping

damagebefore use andserviced annually by

aprofessionalserviceperson.Morefrequent

cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It

is imperative that control compartments, and

circulating air passageways of the appliance

be kept clean and free from excessive lint from

carpeting.

4) See general construction and assembly in-

structions. The appliance and vent should be

enclosedwheninstalledinorpassingthrougha

livingarea,wherechildrenmaycomeincontact

with it.

5) Thisappliancemustbeconnectedtothespeci-

fied vent and termination cap to the outside of

the building envelope. Never vent to another

room or inside a building. Make sure that the

vent is fitted as per the instructions starting in

the "Venting" section.

6) Inspecttheventingsystemannuallyforblockage

and any signs of deterioration.

7) Venting terminals shall not be recessed into a

wall or siding.

8) Any safety glass removed for servicing must

be replaced prior to operating the appliance.

9) To prevent injury, do not allow anyone who is

unfamiliarwiththeoperationtousethefireplace.

1) Provide adequate clearances for servicing,

properoperationandaroundtheairopenings

into the combustion chamber.

2) The appliance must be installed on a flat,

solid, continuous surface (e.g. wood, metal,

concrete). This may be the floor, or it can be

raised up on a platform to enhance its visual

impact. The appliance may be installed on

carpeting,tile,woodflooringorothercombus-

tible material, because the appliance's metal

pedestalbaseextendsthefullwidthanddepth

of the appliance. The ULTIMATE Rear Vent

Direct Vent Freestanding Gas Stove can be

installed in a wide variety of ways and will fit

nearly any room layout. It may be installed in

arecessedposition,framedoutintotheroom,

or across a corner.

3) The ULTIMATE Rear Vent Direct Vent Free-

standingGasStoveisapprovedformanufac-

tured home installations, see "Clearances to

Combustible"to "Rigid PipeVenting- Vertical

Terminations"sectionfortherequiredventar-

rangements. If installed into a manufactured

home the unit must be bolted down to the

floor.

4) We recommend that you plan your installa-

tion on paper using exact measurements for

clearancesandfloorprotectionbeforeactually

installing this appliance. Have a qualified

building inspector review your plans before

installation.

Emissions from burning wood or gas could

contain chemicals known to the State of Cali-

fornia to cause cancer, birth defects or other

reproductive harm.