2

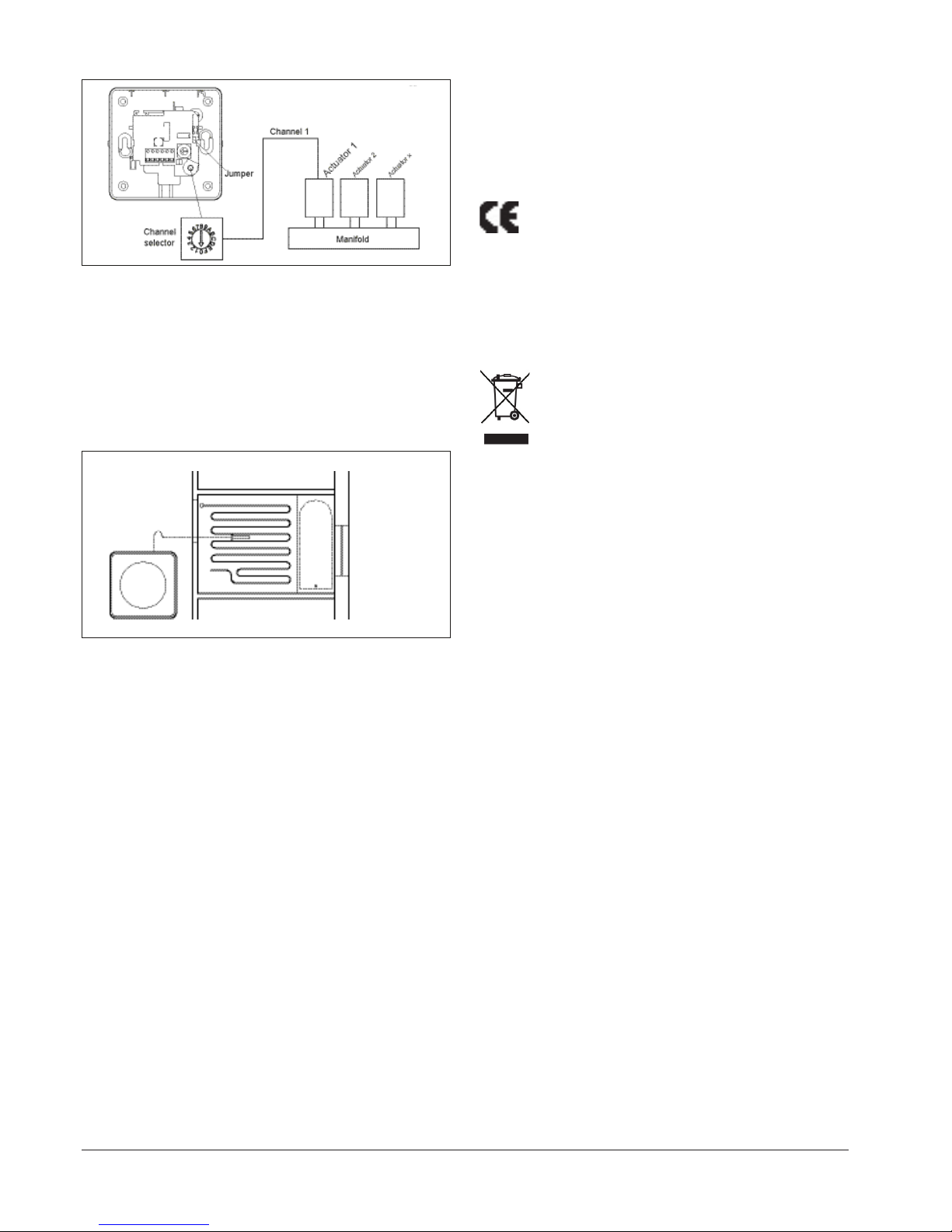

Fig. 5

BR1025A05a

Mounting of floor limit sensor (fig. 6)

REH TD3: Floor limit sensor

Units with floor limit sensor have a mechanical jumper on the printed circuit

board allowing limits to be set for MIN. or MAX. temperature regulation. If set for

MAX., the limit setting will be 27°C. If set for MIN., the limit setting will be 17°C.

These temperatures are fixed when used with REHAU BA3 masters unless the

unit has been allocated to a zone group controlled by a REH CT3 room controller.

In this case, the limit settings can be increased or decreased via the room

controller. The limits then set will apply to all relevant room sensors with floor

limit sensor belonging to that group. If a REHAU FC-BMS3 master is used, the

limit settings can be changed using the programming buttons on the master.

Fig. 6

BR1026A04a

Jumper connected: max. limitation

Jumper removed: min. limitation

Jumper location, see fig. 5.

Max. temperature limitation is used to prevent the floor from becoming

too warm. This may be required if special floor surfaces (e.g. solid wood)

are used. The sensor should be positioned where it can read the true

temperature of the floor and should always be within the heated area.

Min. temperature limitation is used to keep the floor surface warm,

irrespective of room temperature. In tiled bathrooms or pool areas, for

example, water will dry more quickly if the floor surface is kept warm. The

sensor should be positioned where it can read the true temperature of the

floor and should always be within the heated area.

To ease replacement, we recommend that all floor sensors are mounted

in a tube positioned between two heating pipes. The inner end of the tube

should be sealed, and the floor sensor cable led back to the bottom of

the wall. If required, the sensor cable can be extended up to 30 m with

standard installation cable.

REH TM3: Use of external room sensor

A remote room sensor can be used instead of the built-in sensor by

connecting the jumper across the two-pin bridge on the printed circuit

board beneath the room sensor cover. From the factory, the jumper is

“parked”on one pin. Jumper location, see fig. 5.

Jumper connected: External room sensor

Jumper removed: Built-in room sensor

See the Installation Manual for further instructions.

Maintenance

The unit is maintenance free.

Keep the air vents (openings) on the unit clean and unobstructed at all

times.

Certications

CE marking

REHAU Limited hereby declares that the product conforms with the following

Directives of the European Parliament and of the Council:

• CE marking: 1993/68/EEC

• EMC - electromagnetic compatibility: 2004/108/EC

• RoHS - restriction on the use of certain hazardous substances: 2011/65/

EU

• WEEE - waste electrical and electronic equipment: 2012/19/EU

Applied standard(s)

EN 61000-6-2, EN 61000-6-3

Disposal and recycling

Recycling of packaging

Protect the environment by disposing of the packaging in accordance with

local regulations for waste processing.

Disposal of the product

Equipment containing electrical components must not be

disposed of together with domestic waste.

It must be collected separately along with other electrical and

electronic waste according to local and currently valid legislation.

Technical Specifications

Purpose of control..................Wired electronic room sensor for controlling

hydronic floor heating and cooling

Connection type ................................2-wire, 5 V, communication bus

Cable type ...............................Standard installation cable ≥0.25 mm²

Cable length ...................Up to 300 m with max. 100 m between two units

Control principle ..................................................PI or ON/OFF

Ambient operating temperature ........................................0/+40°C

Floor limit sensor .....................................................Max. 30 m

Power drain .............................................................<1 mA

Temperature adjustment ..................................................±4°C

Functions REH TA3................................................... None

REH TM3, REH TD3........Auto, comfort, setback, frost protection

Room sensor ...........................................................Internal

Floor limit sensor

REH TA3, REH TM3......................................... None

REH TD3 ........................................Incl. floor sensor

Mounting method..................For mounting direct on wall or in wall socket

Enclosure rating ...........................................................IP 21

Dimensions .........................................H/86.0, W/86.0, D/25.5 mm