Notes on this Technical Information

Validity

This Technical Information is valid for Australia.

Definitions

• Supply lines or piping consist of pipes and their joints (e.g.

compression sleeves, fittings, threads, or similar). This

applies to all pipes in this Technical Information.

• Piping systems, installations, systems, etc. consist of the

pipes and the necessary components.

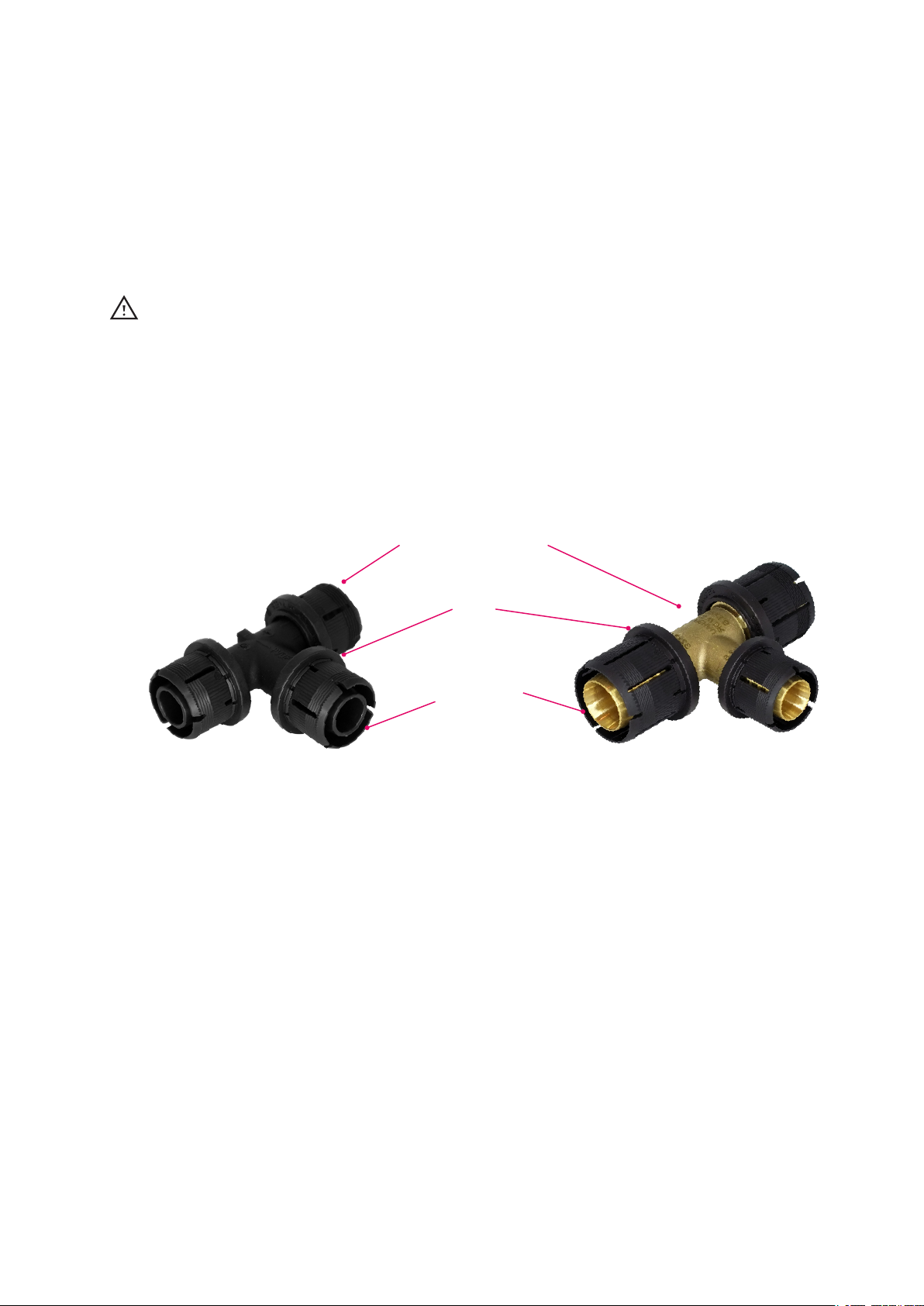

• Connection components consist of EDGETM fittings

(including pre-assembled components – Clip and inner

sleeves) with the corresponding compression sleeves and

pipes as well as seals and screw connections.

• EDGETM connection – means a REHAU compression sleeve

connection to form a seal between an EDGETM fitting and

EDGETM pipe

• EDGETM fitting – means REHAU EDGETM fittings made of

engineered polymer or DZR brass with at least one EDGETM

connection (e.g. coupler, elbow, T-piece, adapter, union

connector etc)

• EDGETM pipe or EDGETM PE-Xa pipe – means REHAU

EDGETM pipe SDR 9 made of PE-Xa (silver, red, green and

lilac)

• Pipe support channel – means REHAU’s zinc plated clip-on

channel to limit thermal length changes and pipe sagging in

EDGETM pipes

Explanation of symbols

Safety information

Legal information

Important information, which needs

to be taken into account

Information on the Internet

Your benefits/advantages

01. Information and safety advice

Intended use

The REHAU EDGETM piping system components and

compression sleeve jointing technique is considered as

propriety systems and shall be designed, installed and

operated in accordance to REHAU’s Technical Information.

REHAU EDGETM piping system shall only be used for the

following applications:

EDGETM silver pipes - hot and cold water supply

EDGETM red pipes - hot water supply

EDGETM green pipes - rainwater plumbing

EDGETM lilac pipes - recycled water plumbing

Any other use that does not fall within the intended use of the

system is prohibited.

Further, REHAU EDGETM piping system shall be operated

with the operating parameters set forth in this Technical

Information. Not adhering to the operating parameters will

void the REHAU warranty.

Piping network calculation

In addition to the information contained in this technical

document, various services are offered for the sizing of

drinking water and heating systems by REHAU. For extensive

advice, please consult your REHAU sales office

When installing this pipe system, please observe all

applicable national and international regulations on

installation, accident prevention and safety together with

the information contained in this Manual.

Also observe the applicable laws, standards, guidelines

and regulations (e.g. DIN, EN, ISO, NCC, NZBC, AS/NZS)

as well as regulations on environmental protection,

provisions of professional associations and regulations of

the local public utility companies.

Any applications not described in this Manual - i.e.

Non-standard applications - must be discussed with our

Technical Applications Department. For more detailed

advice, please contact your REHAU Sales Office.

This design and installation information is related solely

to the specific REHAU product. Occasionally, references

are made to parts of applicable standards and directives.

Always observe the current version of any guidelines,

standards or directives.

Further standards, directives and guidelines related to

the design, installation and operation of drinking water,

heating or buildings services systems should also be

referred to, but these do not form part of this Technical

Information.

Safety advice and operating instructions

• Please read these safety instructions and technical

information carefully and completely for your own safety

and other’s before beginning the installations.

• If you have any questions or need further clarifications

• on the safety instructions and/or the individual installation

instructions, please discuss with REHAU

• Failure to observe the safety information/instructions

can result in damage to property and persons.