HBSX‐8‐RH04/14 2ReichUSACorporation,Mahwah,NJ(201)684‐9400–FAX(201)684‐9401

HUBATTACHMENTTOTHESHAFT– SHRINKDISC

1. Inspecttheshaftandhubboresthattheyarecleanandfreeofburrs.DONOTplaceanygreaseontheshaftor

insideofthehubasthiswillnotallowtheneededcoefficientoffrictionbetweenthehubandshaft.The

contactsurfacebetweenthehubandinnerringoftheshrinkdisccanbelightlyoiledforassembly.Forlarger

shrinkdiscs,theinnerringisprotectedwithoiledpaper,whichmustberemovedbeforeassembly.Makea

quickinspectionthattheShrinkDiscscrewthreads/headandtaperedinnerringarecoatedwithgrease.If

not,pleaselubricatethesesurfacesonlywithMolykote Grease.

2. Placetheshrinkdiscontothehubbeforeinstallingthehubontheshaft.

3. Assembletheshrinkdisc/hubontotheshaft.Slidethehubfarenoughontotheshaftsotheshaftendiseven

withthehubfaceortotheminimumrecommendedshaftdepthperthesuppliedcouplingassemblydrawing.

TheminimumshaftdepthshouldnotbechangedwithoutconsultingReichUSA.Thedistancebetweenshaft

hubswillthenbethewidthoftherecommendedspacebetweentheassembledcouplinghalvesfortheHBSX‐

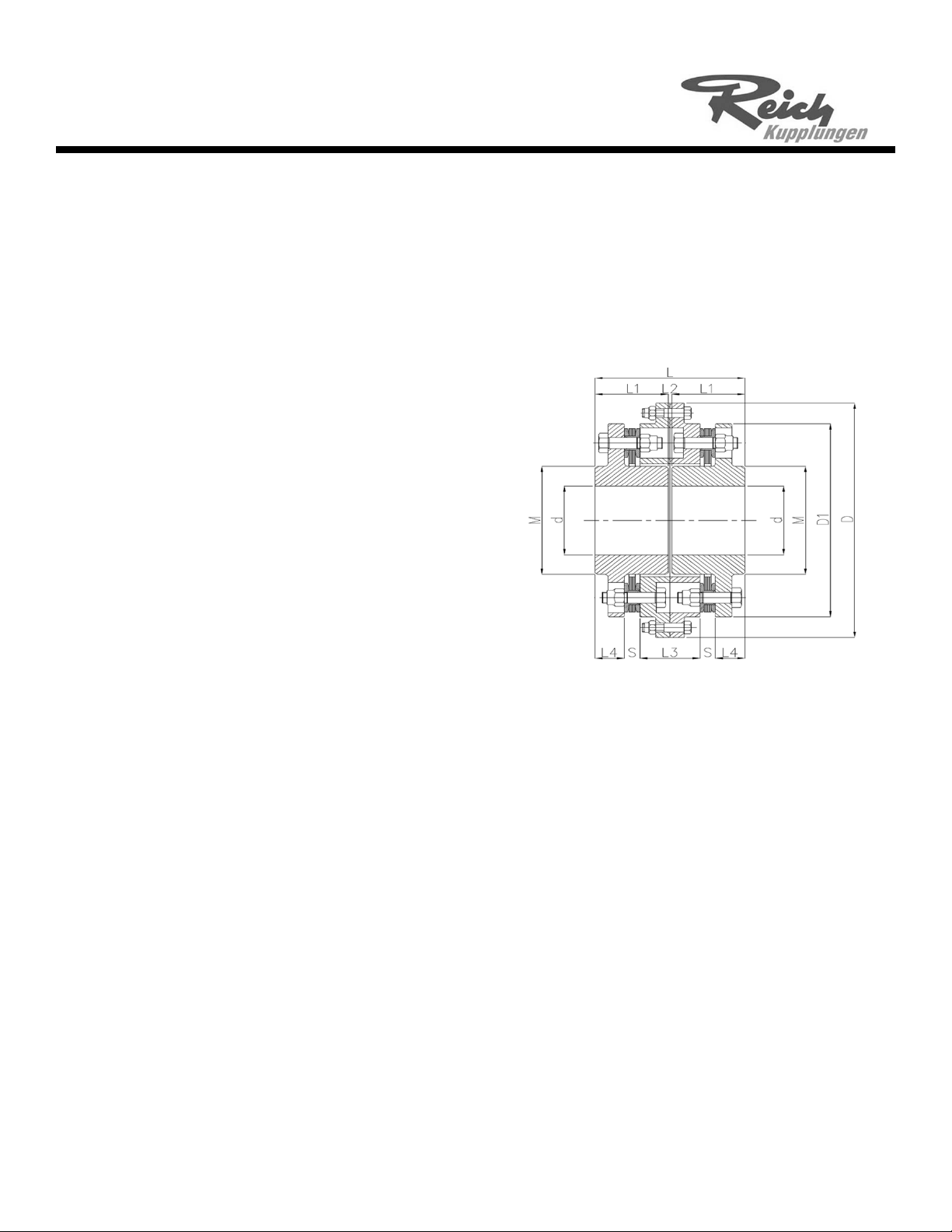

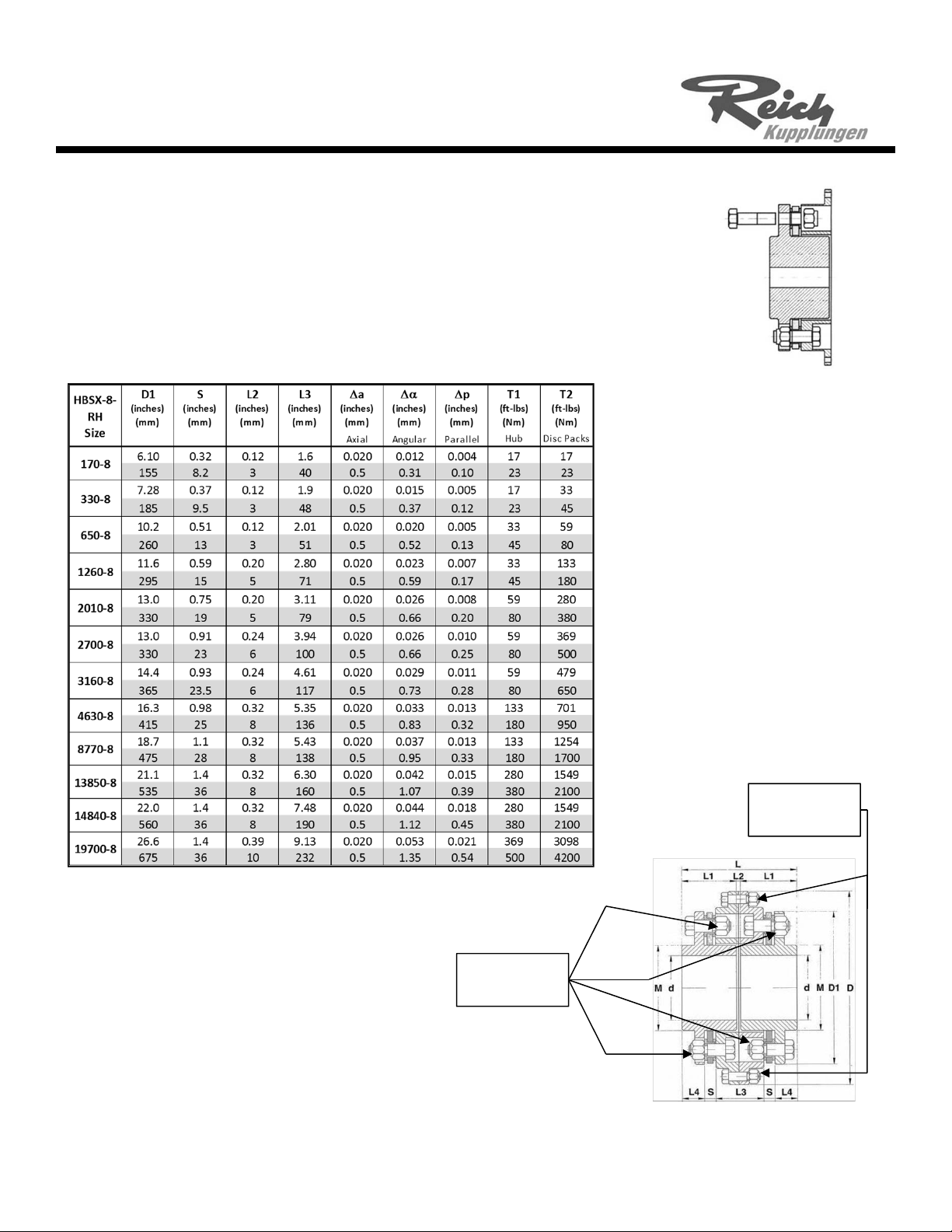

RHconfiguration(seedimensionL2inFigure1andTable1).

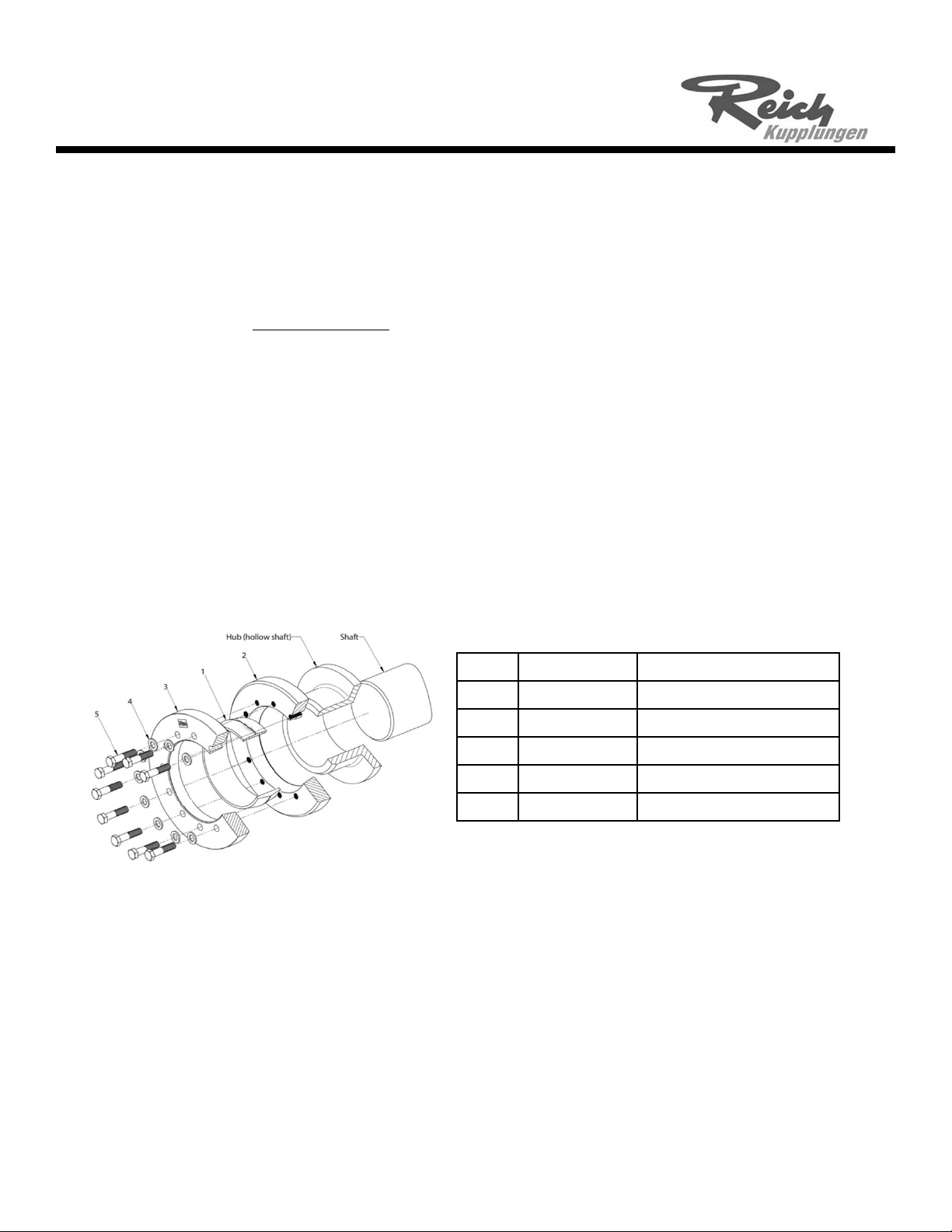

4. Hand‐tightentheclampingscrews(figure2,item5)untiltheshrinkdiscsitsonthehubandthegapbetween

thepressurerings(figure2,items2and3)areeven.

5. Setthetorquewrenchtotherecommendedshrinkdiscscrewtorque.Begintorqueingthescrewsina

clockwiseorcounterclockwisemanner.Donotturnanyscrewsmorethan90degreesatonetime.Thiswill

helpinsurethatthegapbetweentheouterringsremainsasevenaspossible.Installationiscompletewhen

allscrewsareattherecommendedshrinkdiscbolttorque.

6. Afterfollowingthecouplinginstructionsforaxialalignment,usethecorrect‘HubInstallationinstructions’for

thesecondhub.

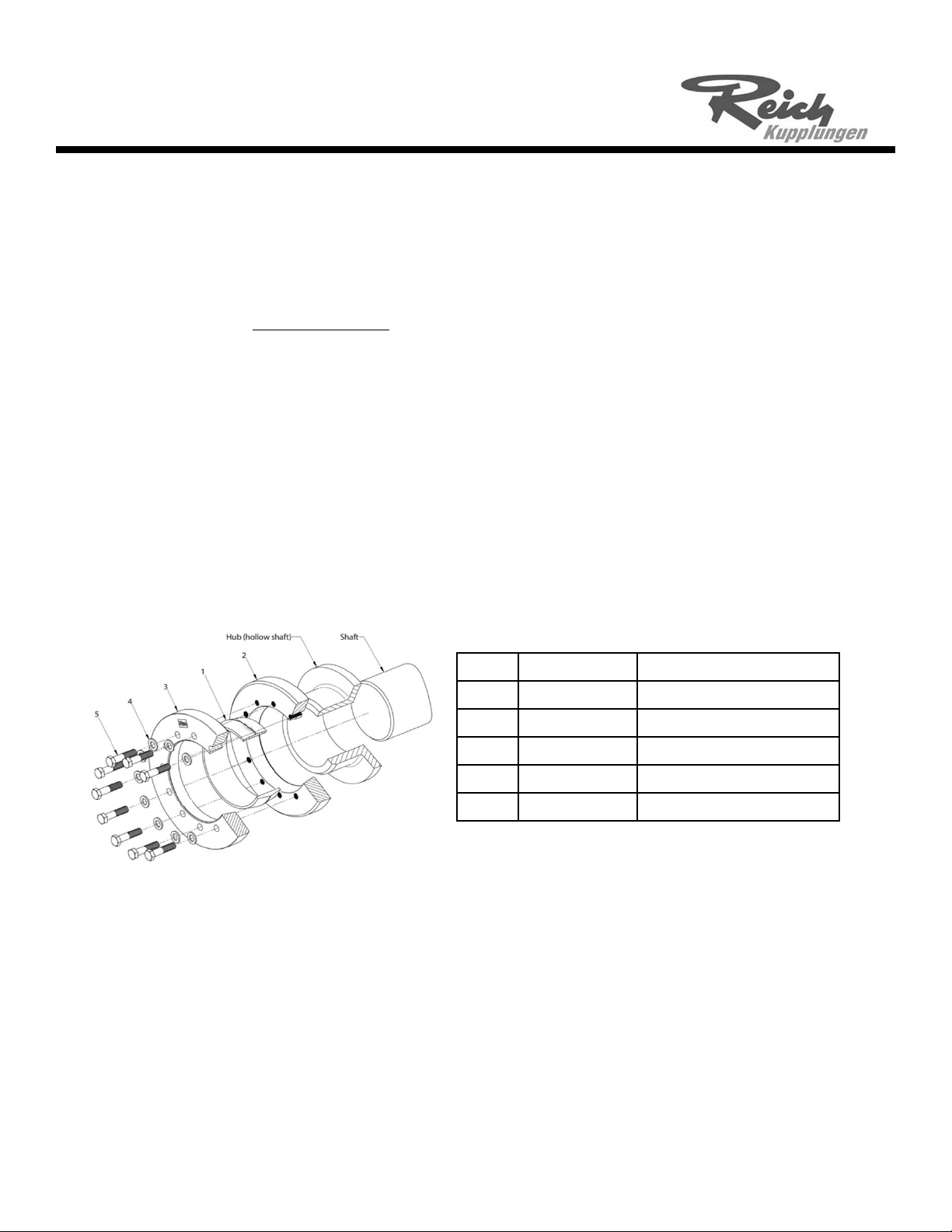

Part Quantity Description

1 1 Innerring

2 1 Pressureringwiththreaded bore

3 1 Pressureringwiththrough bore

4Seeassemblydrawing Washer‐ onlyasneeded

5See assemblydrawing Clamping screw

Figure2Shrinkdisccomponents

R‐FlexHBSX‐8‐RHSeries

AssemblyInstructionscont.

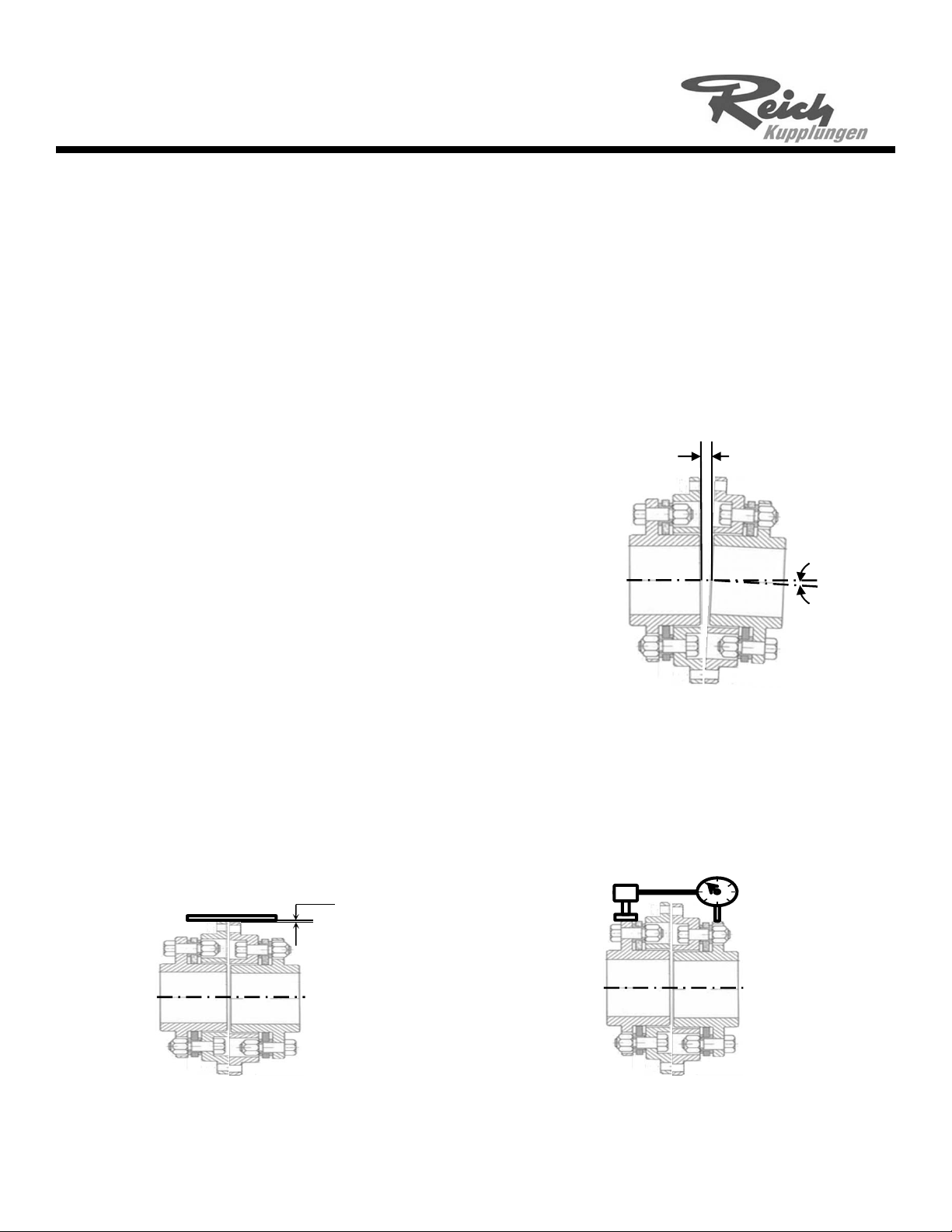

MACHINERYALIGNMENT

ReichUSAR‐flexcouplingscantoleratemisalignmentsthatvarywiththenumberofdiscpackbolts.Forexample,a4‐

boltcouplingallowsamaximumangularmisalignmentof1°,whereasan8‐boltcouplingallowsamaximumangular

misalignmentof0.5°.Misalignmentunderworkingconditionscanchangeduetomanyfactors,suchasthermal

growth,magneticcentering,andsettlingofthecoupledcomponents.Carefulinitialalignmentwillpermitthecoupling

tooperateatfullcapacityandallowforsomefutureoperationalmisalignments.Theinitialmisalignmentvaluesin

Table1areforgeneraluseandcanvaryinspecificcases.Afterhavingproperlyalignedthecoupling,makesurethat

alltheboltsandnutsaretightenedtotheirpropertorque.Ifpossible,itisagoodideatocheckthetorqueaftersome

hoursofoperationaswell.