Donaldson Company, Inc.© 1998 3

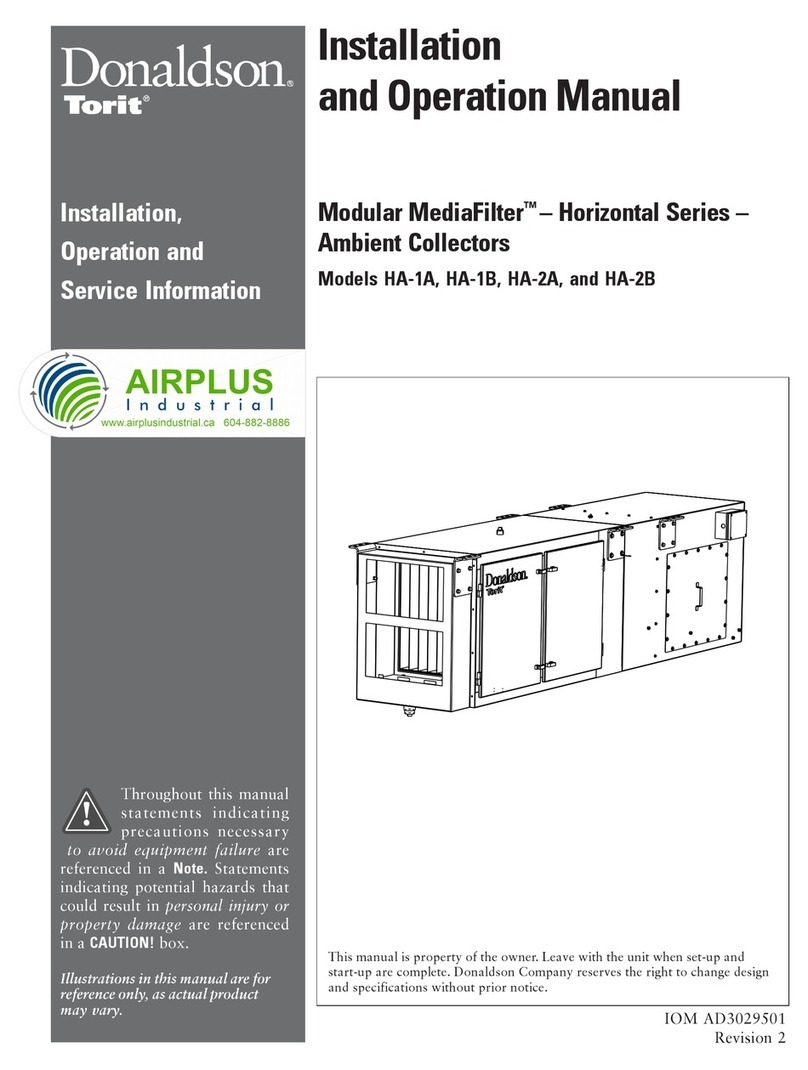

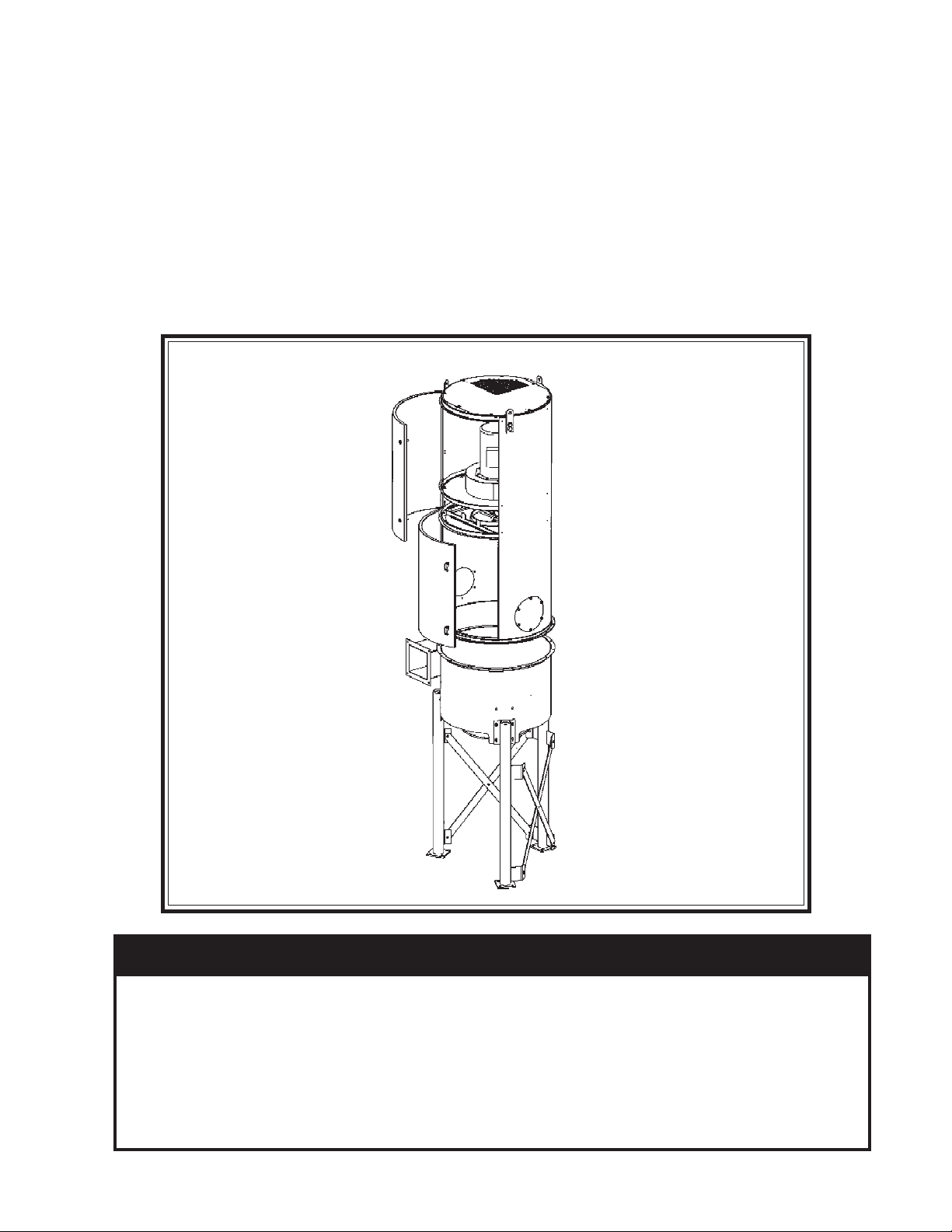

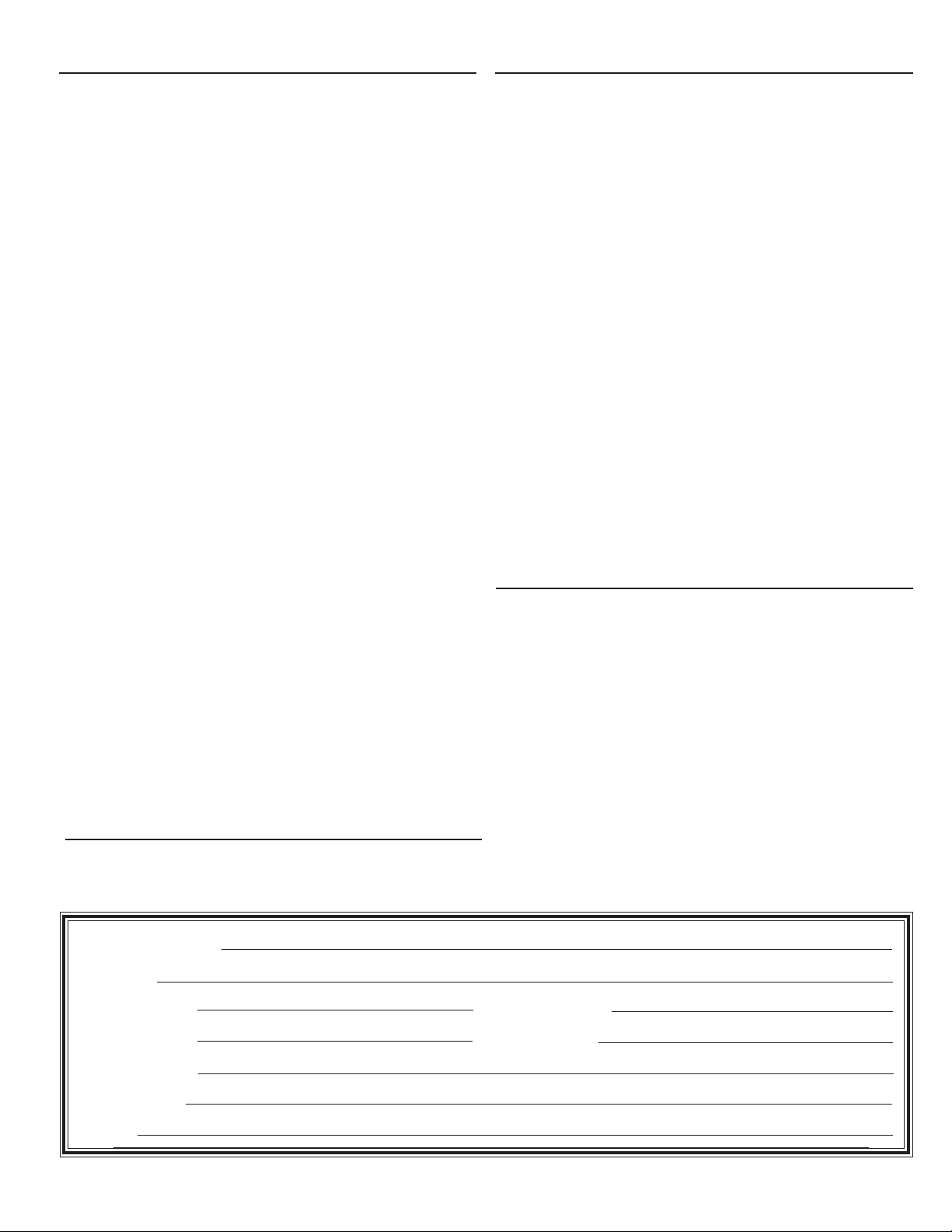

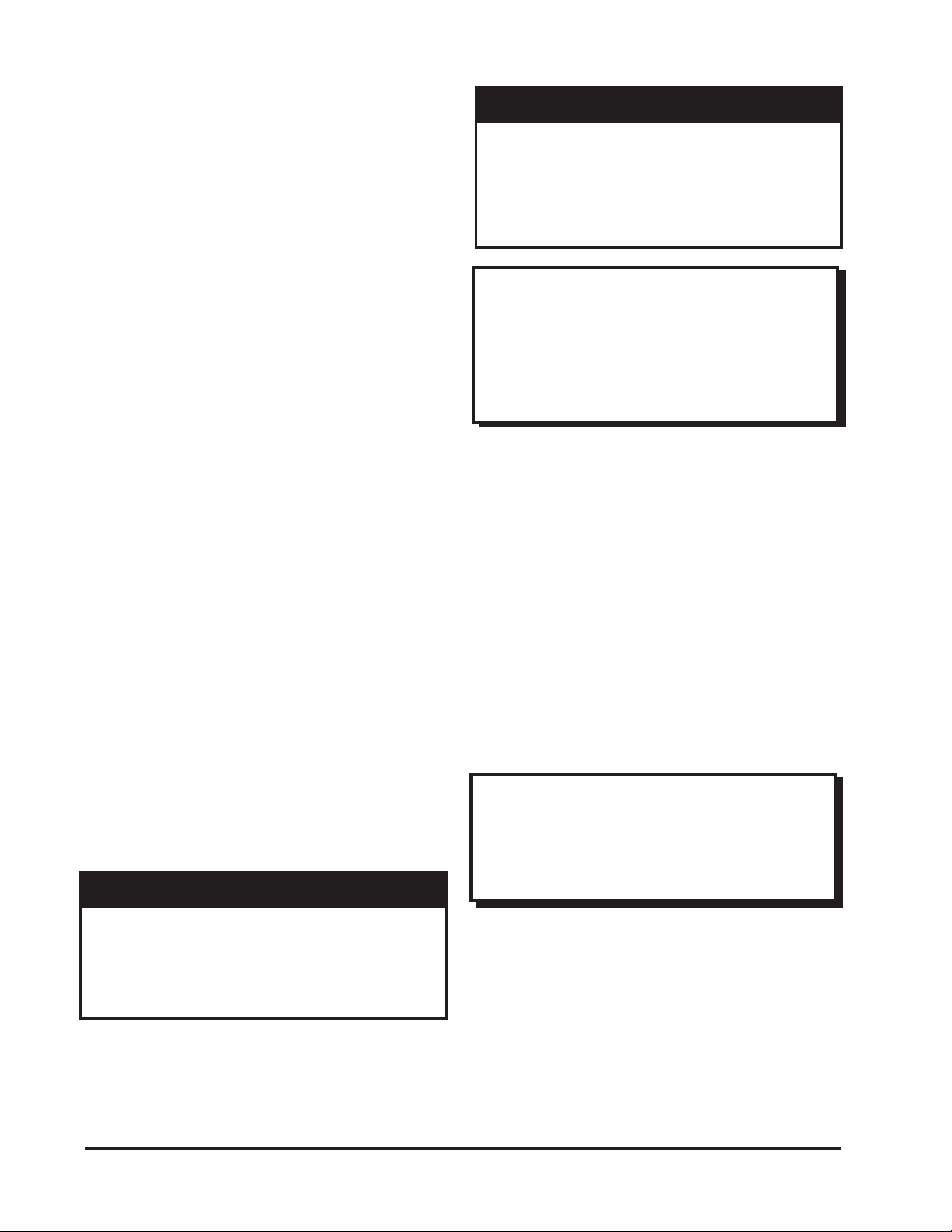

Figure 1 - Phantom View of RVS Dust Collector ... 4

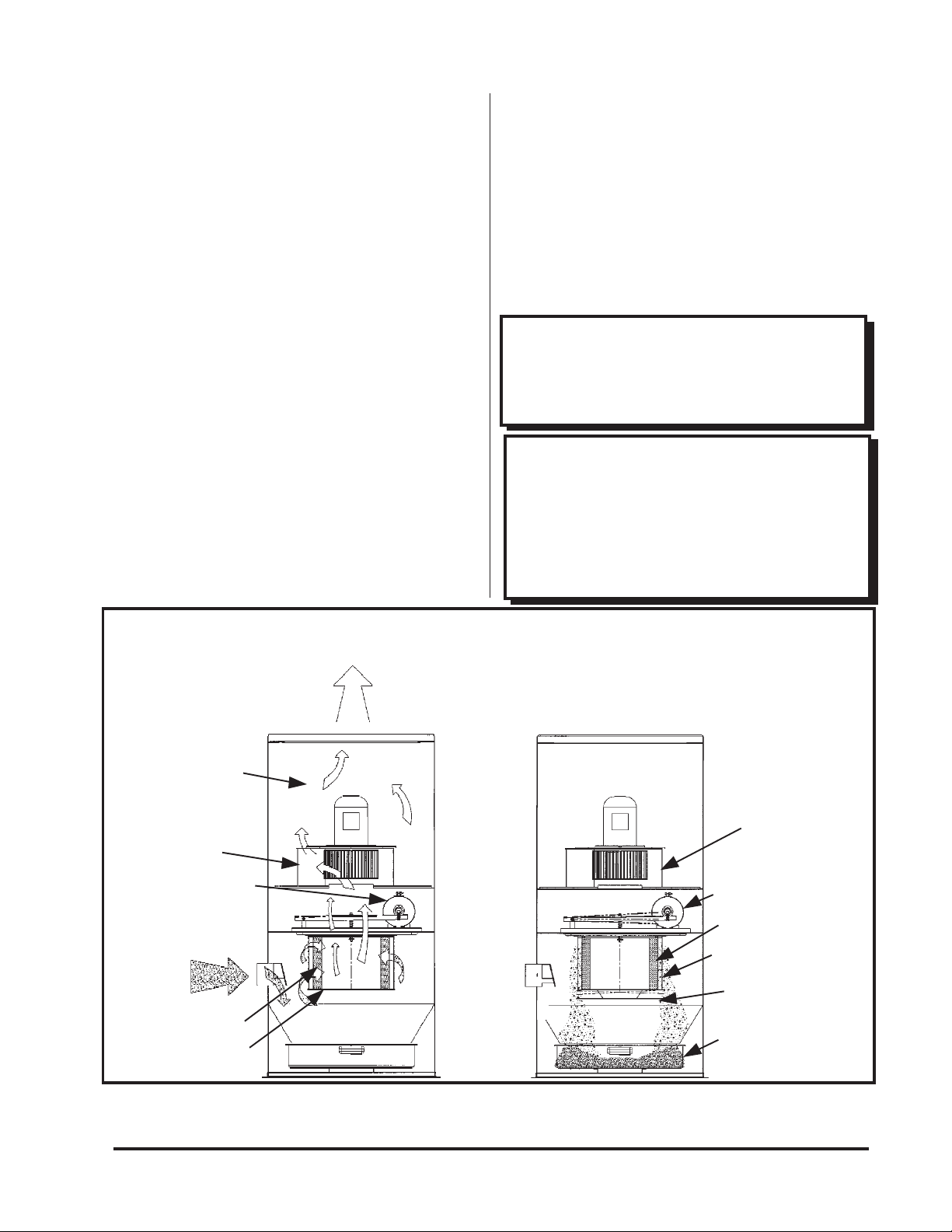

Figure 2 - Operational Schematics ......................... 5

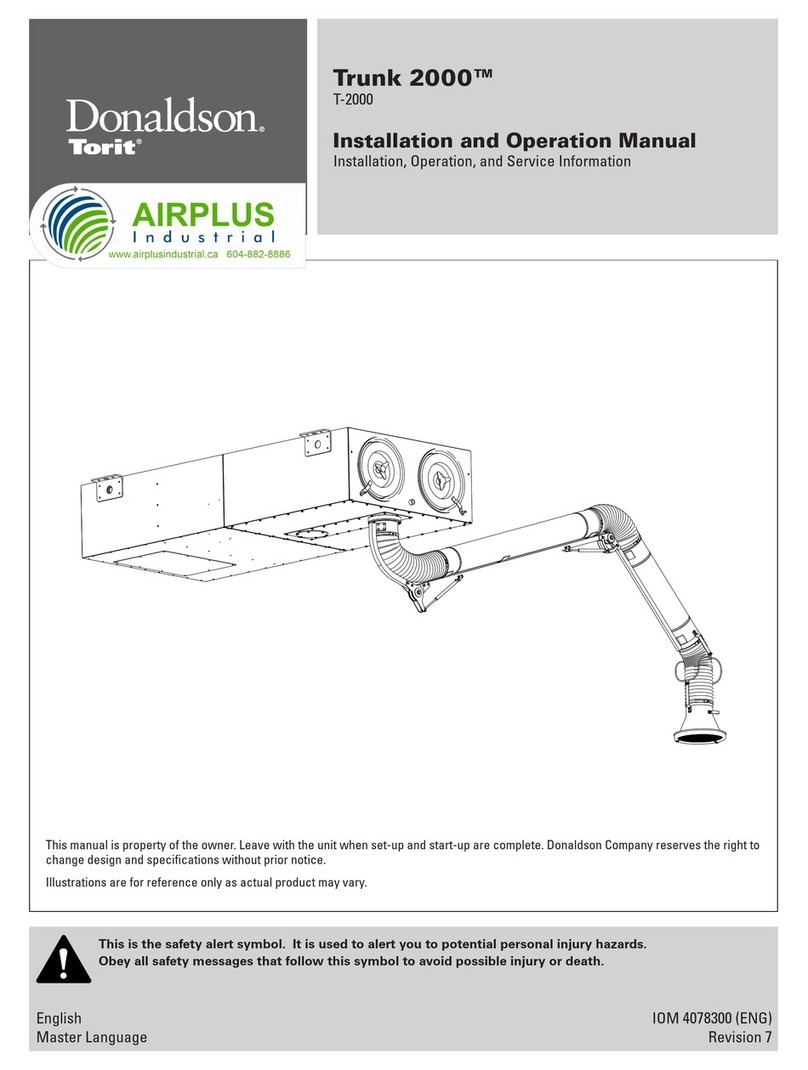

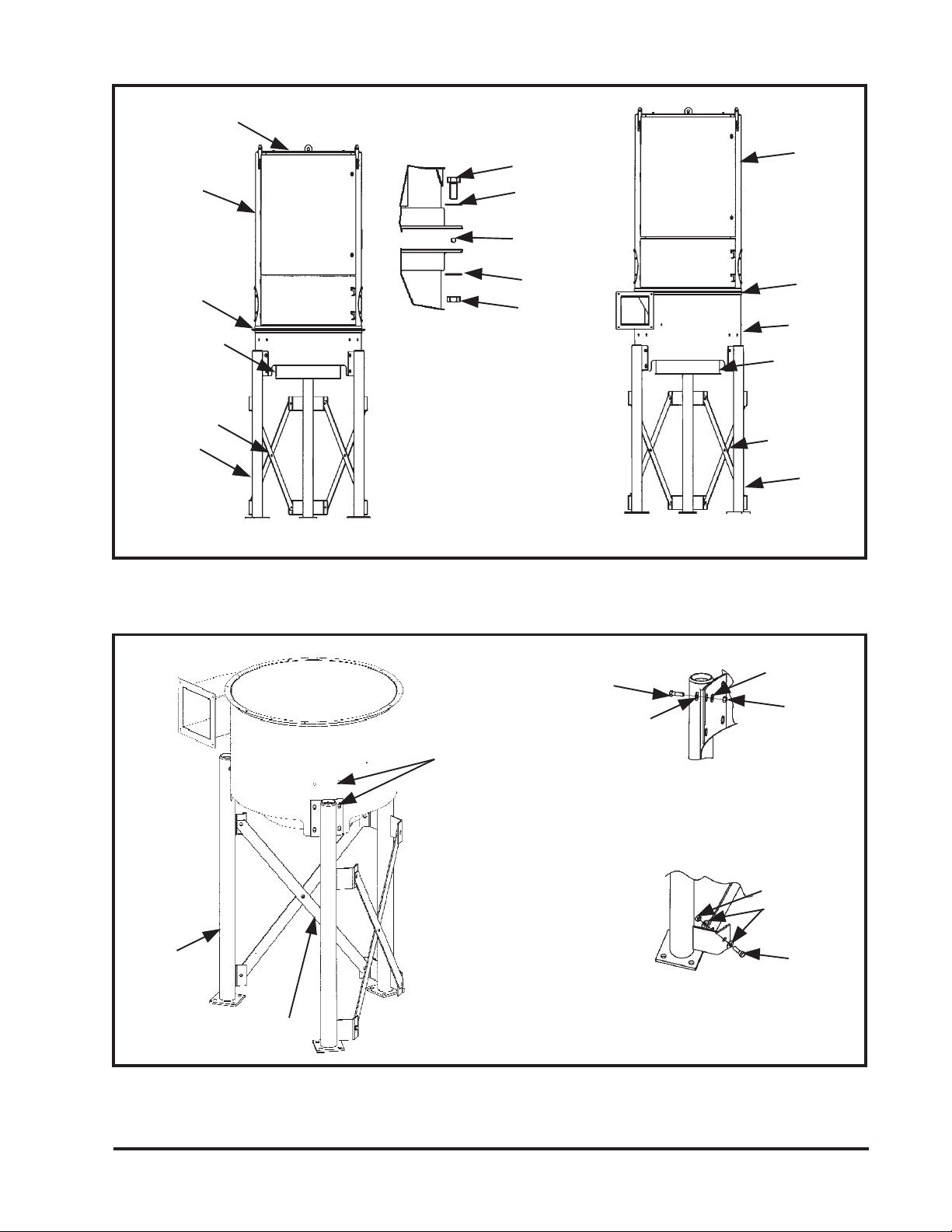

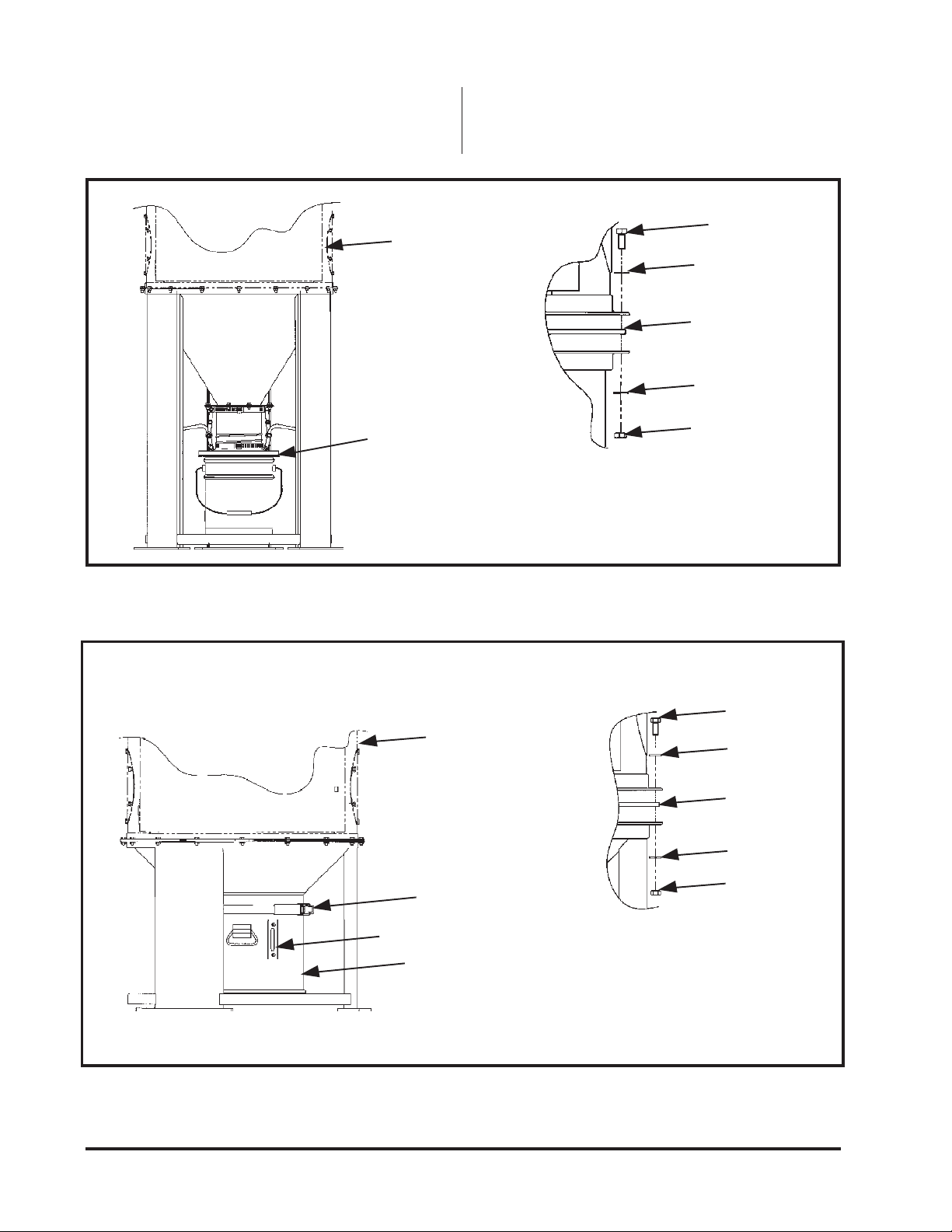

Figure 3 - Hopper and Separator Model

Installation ........................................... 7

Figure 4 - Legs to Hopper Separator Installation ... 7

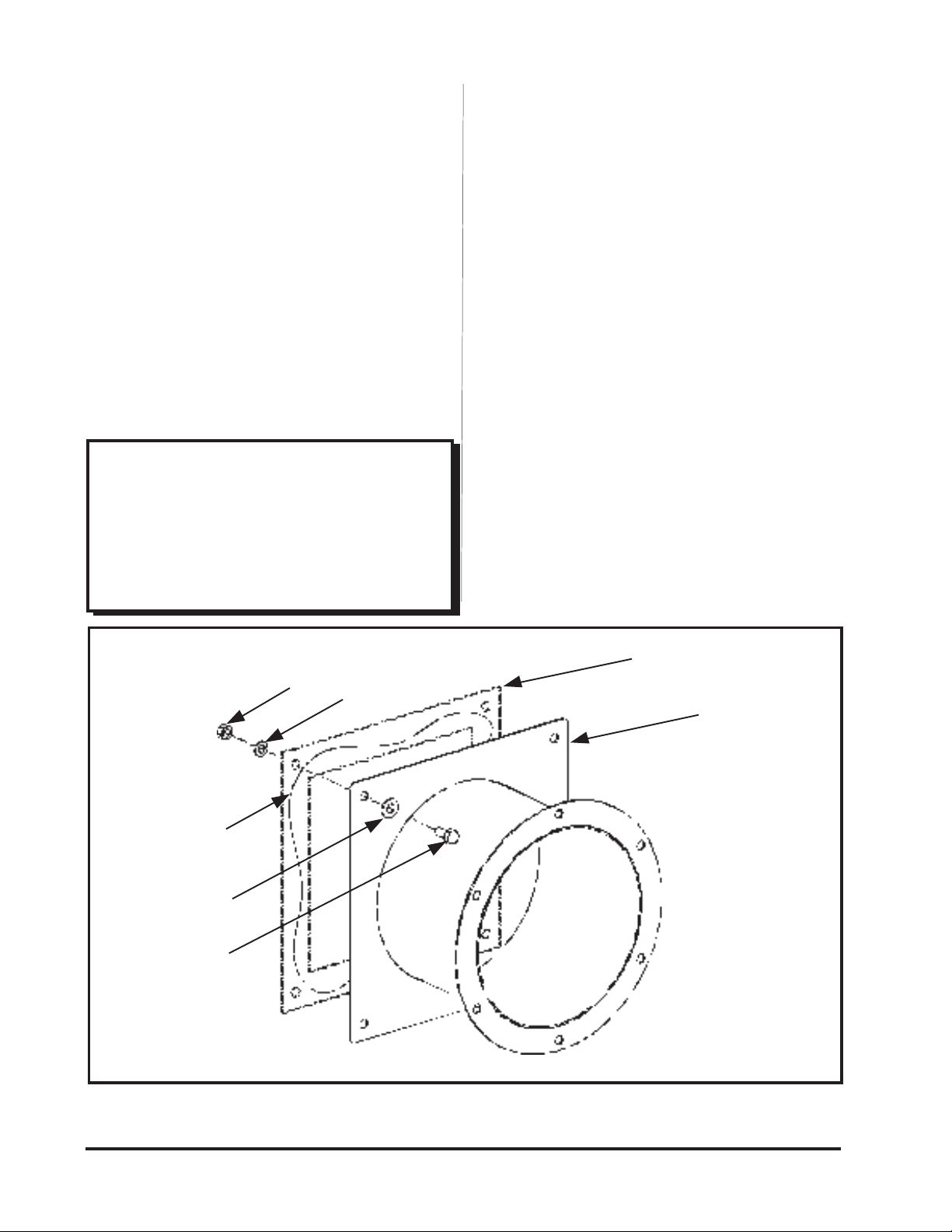

Figure 5 - Square to Round Adapter installation ... 8

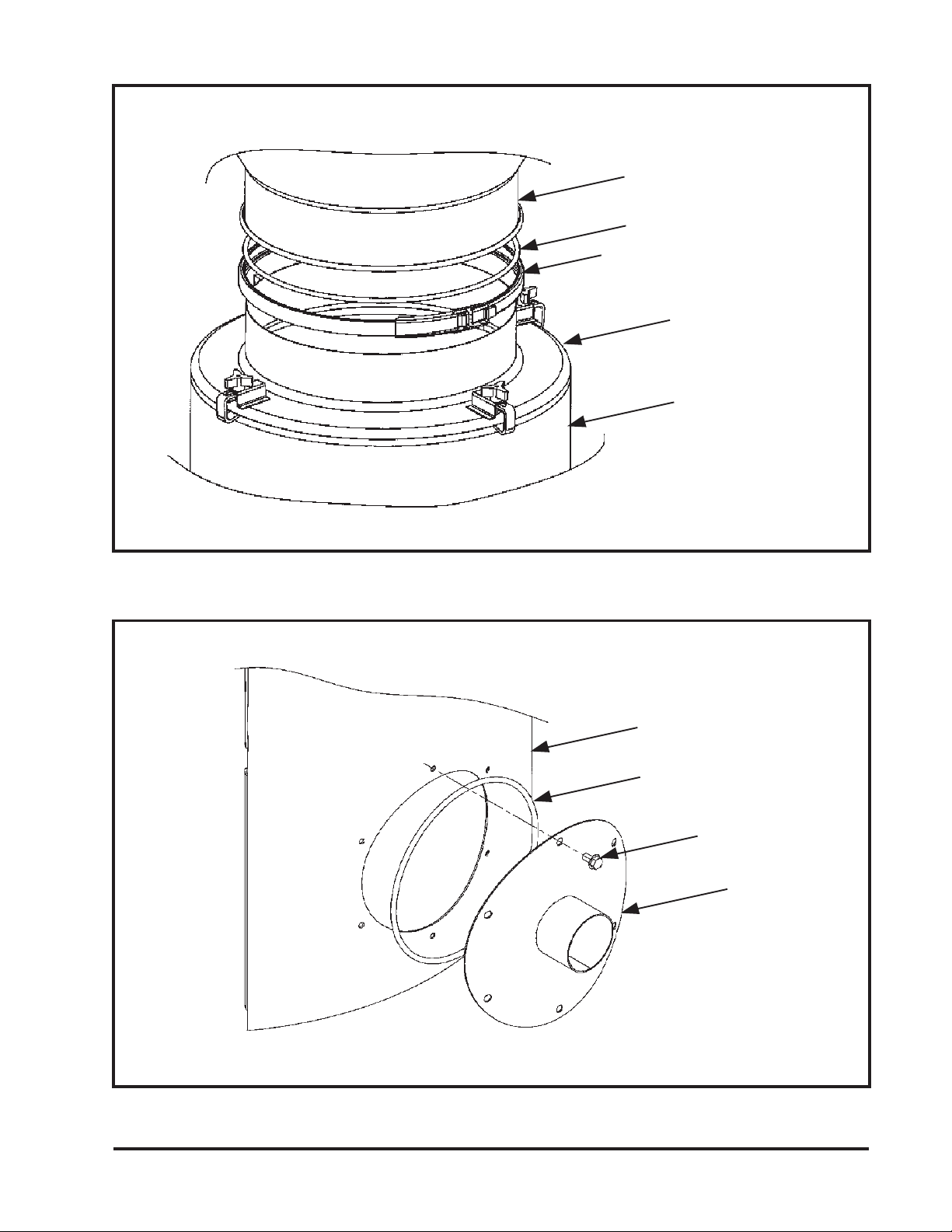

Figure 6 - 55-Gallon Drum Cover Pack

Installation ........................................... 9

Figure 7 - Inlet Collar Installation ......................... 9

Figure 8 - 5-Gallon Pail Pack Installation ............. 10

Figure 9 - 40-Liter Pail Pack Installation .............. 10

Figure 10 - Silencer Installation .............................. 11

Figure 11 - HEPA Filter Installation ....................... 12

Figure 12 - Outriggers Installation ......................... 13

Figure 13 - Ambient and Delta Pressure Switch

Installation .......................................... 14

Figure 14 - Magnehelic Gage Installation ............... 15

Figure 15 - 5-Gallon Pail Pack Insert...................... 15

Figure 16 - Electrical Wiring Diagram .................... 16

Figure 17 - Filter Replacement ............................... 19

Figure 18 - Transformer Voltage Table .................. 26

Figure 19 - Control Box Assembly ......................... 27

Figure 20 - Control Box Assembly ......................... 28

Figure 21 - Wiring ................................................. 29

Figure 22 - Shaker Assembly .................................. 29

Notes and Cautions ..................................... 2

Data Sheet ................................................... 3

1.0 Introduction................................................. 5

1.1 Operational Explanation .............................. 5

1.1.1 Normal Operation ....................................... 5

1.1.2 Filter Cleaning ............................................ 5-6

2.0 Installation................................................... 6

2.1 Inspection .................................................... 6

2.2 Pre-Installation ............................................ 6

2.3 Location ...................................................... 6

2.4 Assembly of Hopper and Separator .............. 8

2.5 Assembly of Hopper and Separator

Attachments................................................. 8

2.5.1 Square to Round Inlet Adapter..................... 8

2.5.2 55-Gallon Drum Cover Pack ........................ 8

2.6 Assembly of Cabinet Attachments ................ 8

2.6.1 Inlet Collar .................................................. 8

2.6.2 5-Gallon Pail Pack ...................................... 10

2.6.3 40-Liter Pail Pack ....................................... 10

2.6.4 Silencer ....................................................... 11

2.6.5 HEPA Filter ................................................ 11

2.6.6 Outrigger Package....................................... 13

2.6.7 Pressure Switch ........................................... 13

2.6.8 Magnehelic®* Gage Pack ............................ 14

2.6.9 5-Gallon Pail Insert ..................................... 14

2.7 Ductwork ................................................... 16

3.0 Electrical ..................................................... 17

4.0 Operation ................................................... 17

5.0 Routine Maintenance .................................. 17

5.1 Dust Drawer Models................................... 17

5.2 Hopper Models ........................................... 17

5.3 Filter Element ............................................. 18

6.0 Service ........................................................ 18

6.1 Filter Replacement .................................... 18-19

7.0 Troubleshooting Guide ............................. 20-25

Parts Ordering Information ....................... 3, 30

Warranty .................................................... 30

FiguresFigures

FiguresFigures

Figures

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

Customer Name

Address

Shipping Date Installation Date

Model Number Serial Number

Filter Medium

Accessories

Other

Data SheetData Sheet

Data SheetData Sheet

Data Sheet

*Magnehelic is a registered trademark of Dwyer Instruments, Inc.