6 Sentry Equipment Corp

General Description

The Sentry® Saf-T-Vise STV-LP1 and Saf-T-Vise STV-LP2 Series insertable tool holders are multi-functional tools that

can be equipped to monitor pipeline corrosion, inject chemical into the process, or sample the pipeline medium. The

holders are engineered to specic site applications with a variety of materials and connection styles and sizes. Design

pressure and temperature requirements determine the model series and sealing technology of the holder.

The holders are designed with a patented locking collet which secures the rod/shaft within the process stream until

released by the operator. A process bleeder valve is standard on holders to allow depressurization of the holder after

closure of the process isolation valve. The ability to fully retract the rod/shaft out of the pipeline while under pressure

allows for pigging without bringing the line down.

The standard Saf-T-Vise STV-LP1 and Saf-T-Vise STV-LP2 Series models are designed to be inserted and retracted by

hand, without the need for a separate tool. However, the Saf-T-Vise STV-LP2 series holder comes standard with tool

threads, allowing the use of a tool for the retraction of a bent or stuck rod.

Specications

STV-LP1 STV-LP2

weight 4 to 7 lb

1.8 to 3.2 kg

10 to 35 lb

4.5 to 16 kg

materials 316 SS 316 SS;

other alloys available

insertion pressure

(MOP)

750 psi at 100°F

52 bar at 38°C

1/4 in: 1000 psi at 100°F

69 bar at 38°C

3/8 in: 750 psi at 100°F

52 bar at 38°C

1/2 in: 420 psi at 100°F

29 bar at 38°C

pressure rating

(MAP)

2000 psi at 100°F

138 bar at 38°C

4000 psi at 100°F

275 bar at 38°C

temperature rating

min/max (seals)

PTFE:

0°F / 450°F

-18°C / 232°C

PTFE: 0°F / 450°F

-18°C / 232°C

graphoil: 0°F / 1000°F

-18°C / 538°C

process connection 1 in NPT ½, ¾, 1, 1½ or 2inNPT

or ange

insertion depth 11, 17, 23, or 29 in

28, 43, 58, or 74 cm

up to 6 ft

up to 1.8 m

rod/shaft OD 3/8 in 1/4, 3/8 or 1/2 in

holder types corrosion coupon, atomizer,

sample or injection quill

Installation

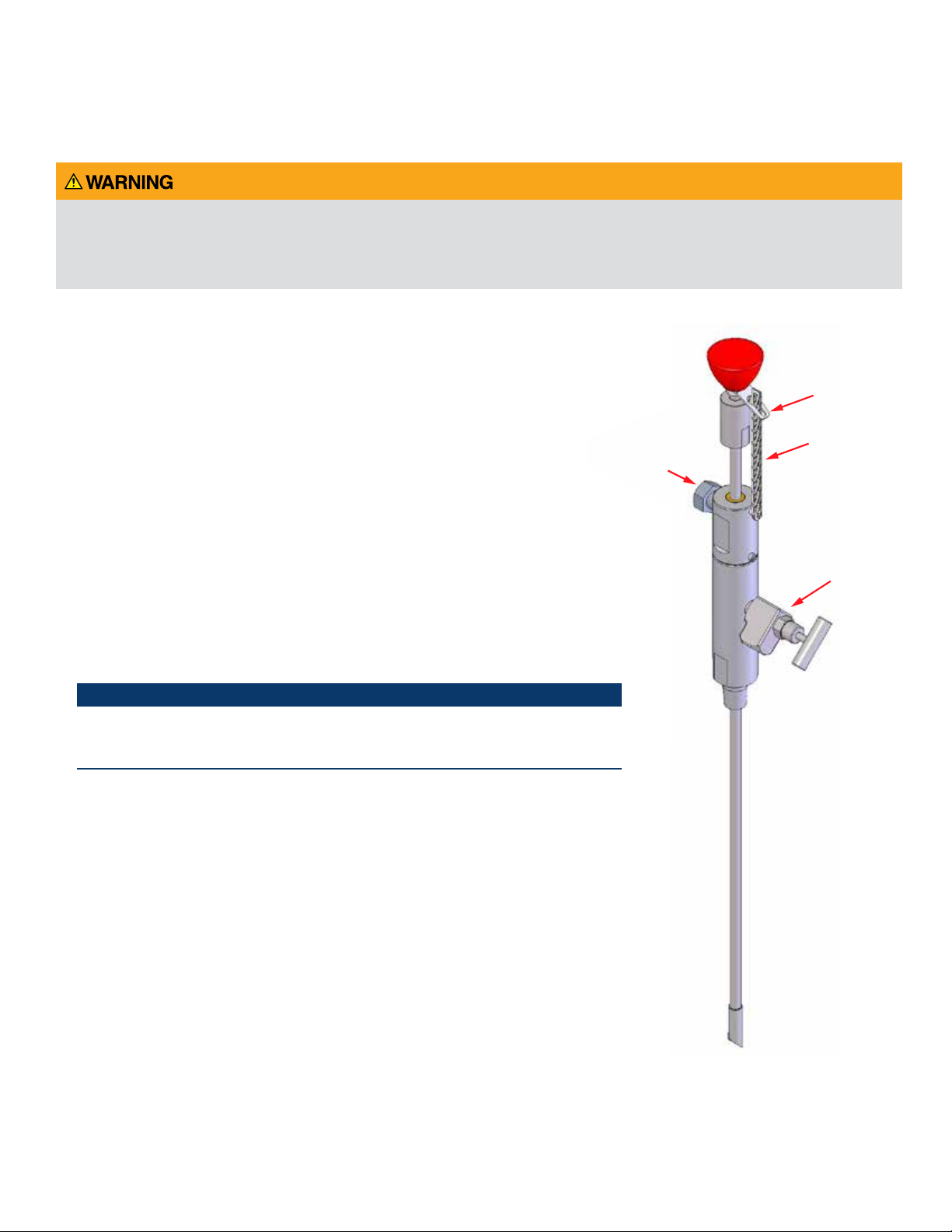

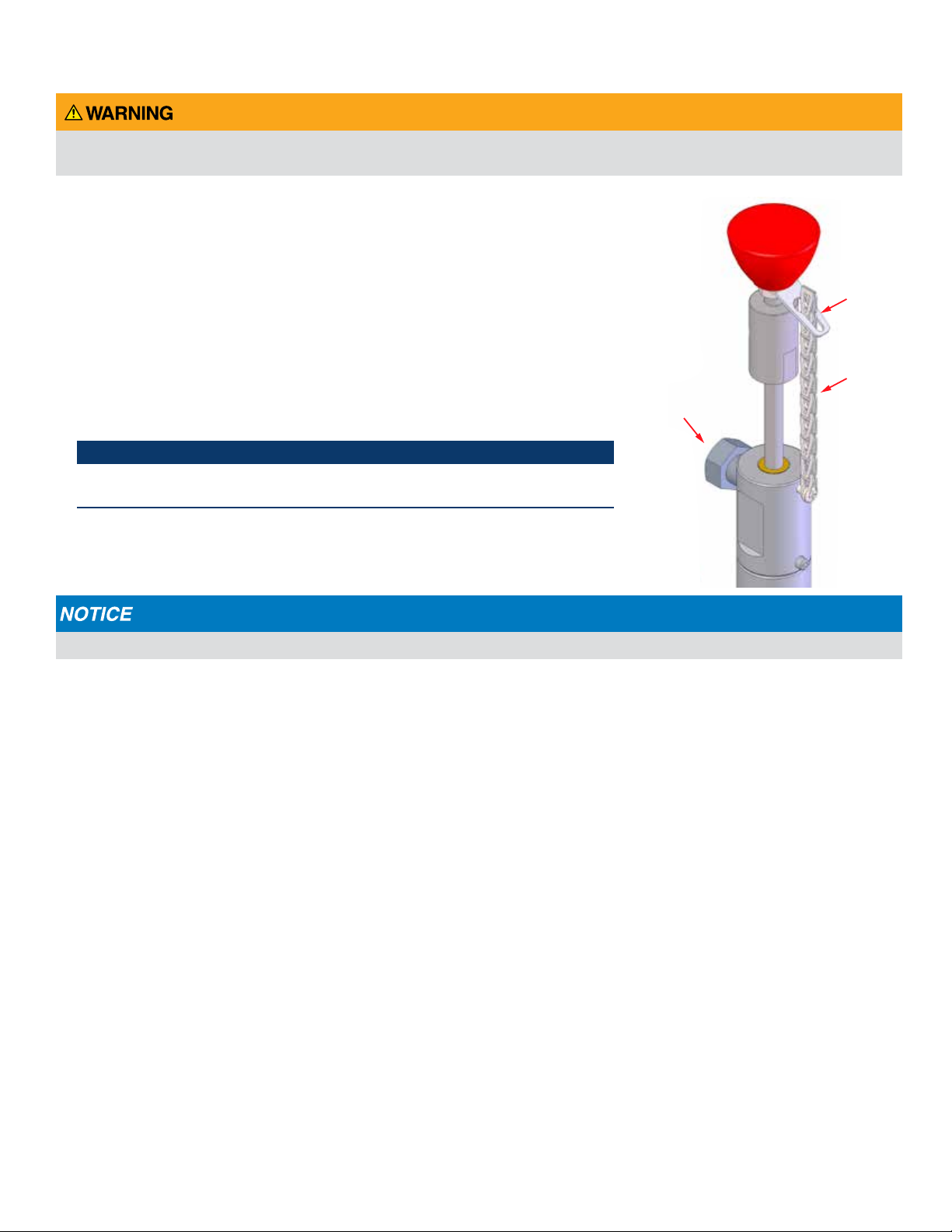

The Saf-T-Vise STV-LP1 and Saf-T-Vise STV-LP2 tool holders attach to a pipeline isolation valve by means of either a

anged or NPT threaded connection. A holder is installed or removed during the operation and maintenance of the

equipment as detailed in the following sections.

Welded Stop

Rod/shaft

Lower body

assembly

Upper body

assembly

Collet

lock bolt

insertion knob

Safety

chain

Upper body

set screw

Bleeder

valve

NPT pipeline

connection

PDF Created on 7/28/2015 1:25:34 PM