TABLE OF CONTENTS

OVERVIEW.....................................................................................3

INSTALLATION TIPS......................................................................3

Tuning Note..................................................................................4

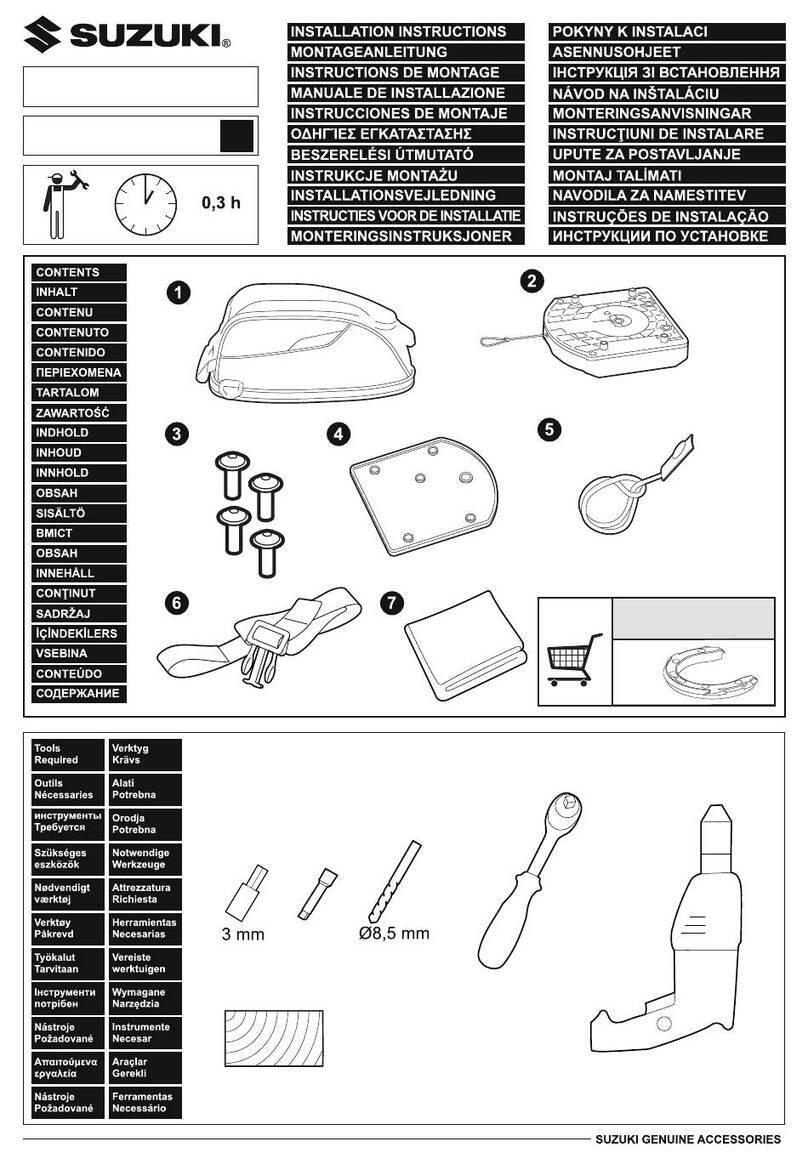

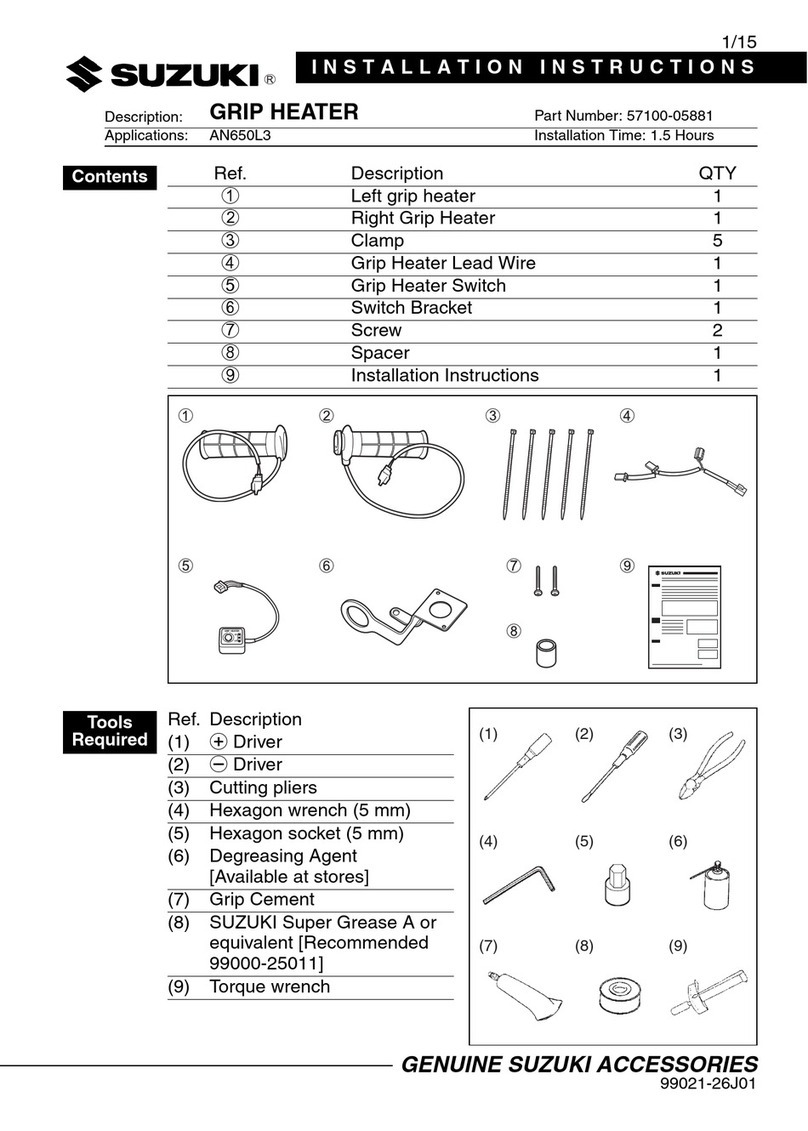

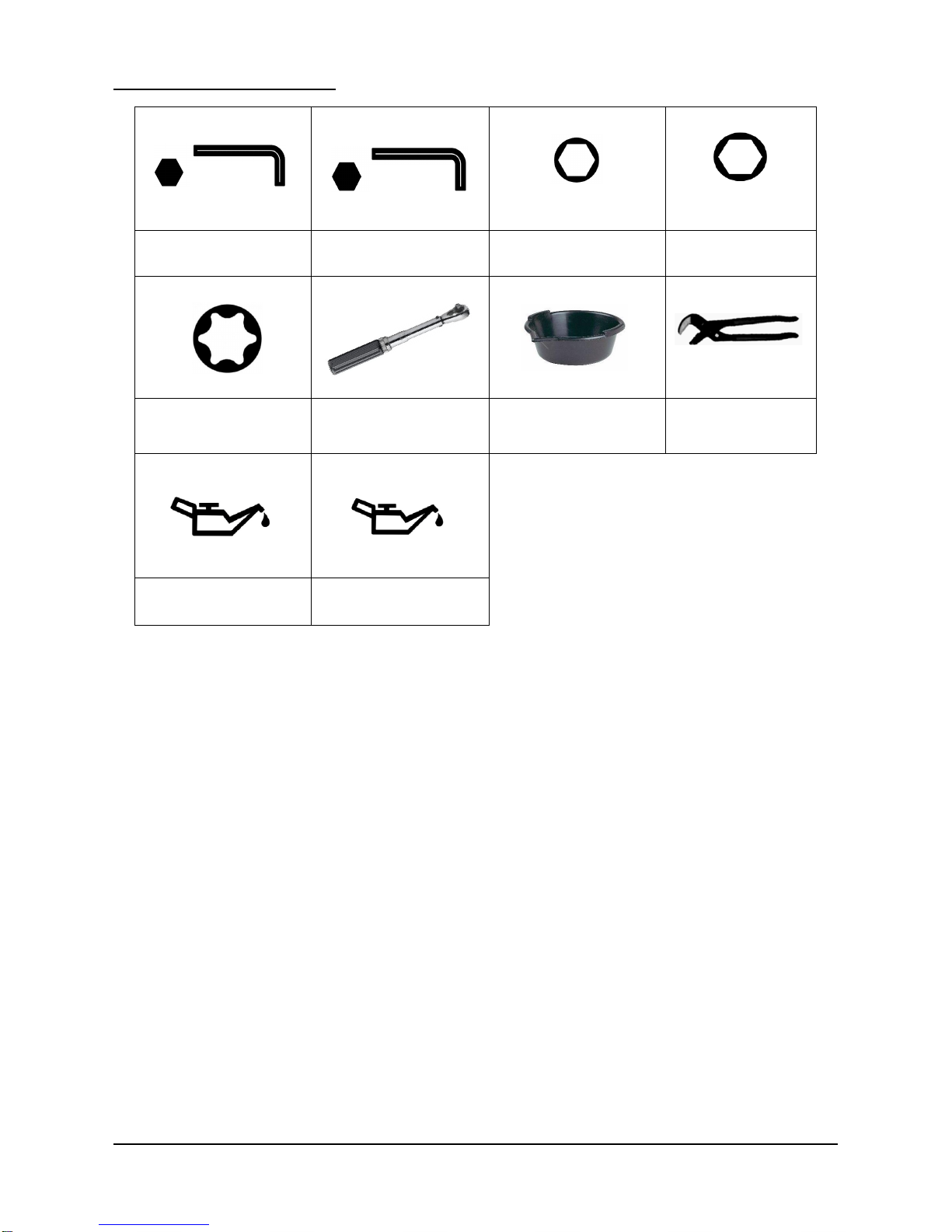

TOOLS NEEDED............................................................................5

INCLUDED PARTS.........................................................................6

DISASSEMBLE THE CLUTCH .......................................................7

INSPECT THE DAMPERS..............................................................9

INSTALL HUBS.............................................................................10

CLUTCH PACK INSTALLATION...................................................12

PRESSURE PLATE INSTALLATION............................................17

SLAVE CYLINDER INSTALLATION.............................................22

Step 1: Bleed the new slave cylinder..........................................22

Step 2: Replace OE slave cylinder.............................................25

SET THE INSTALLED GAP AND VERIFY BY CHECKING FREE

PLAY GAIN ...................................................................................32

Step 1: Find the starting point.....................................................33

Step 2: Learn how to check Free Play Gain...............................34

Two Ways to Check for Free Play Gain .....................................36

The Rubber Band Method..........................................................36

The Hand Method.......................................................................39

Step 3: Break-in the new clutch..................................................41

Step 4: Adjust the installed gap and Recheck Free Play Gain ...43

FREE PLAY GAIN ADJUSTMENTS .............................................45

MAINTENANCE............................................................................46

Disk inspection examples...........................................................48

TROUBLESHOOTING ..................................................................49

Performance issues....................................................................49

Clutch noise................................................................................49

EXP TUNING OPTIONS ...............................................................49

Changing the springs .................................................................50

Configuration chart.....................................................................52