Rekluse Core EXP - Hydraulic Page 5

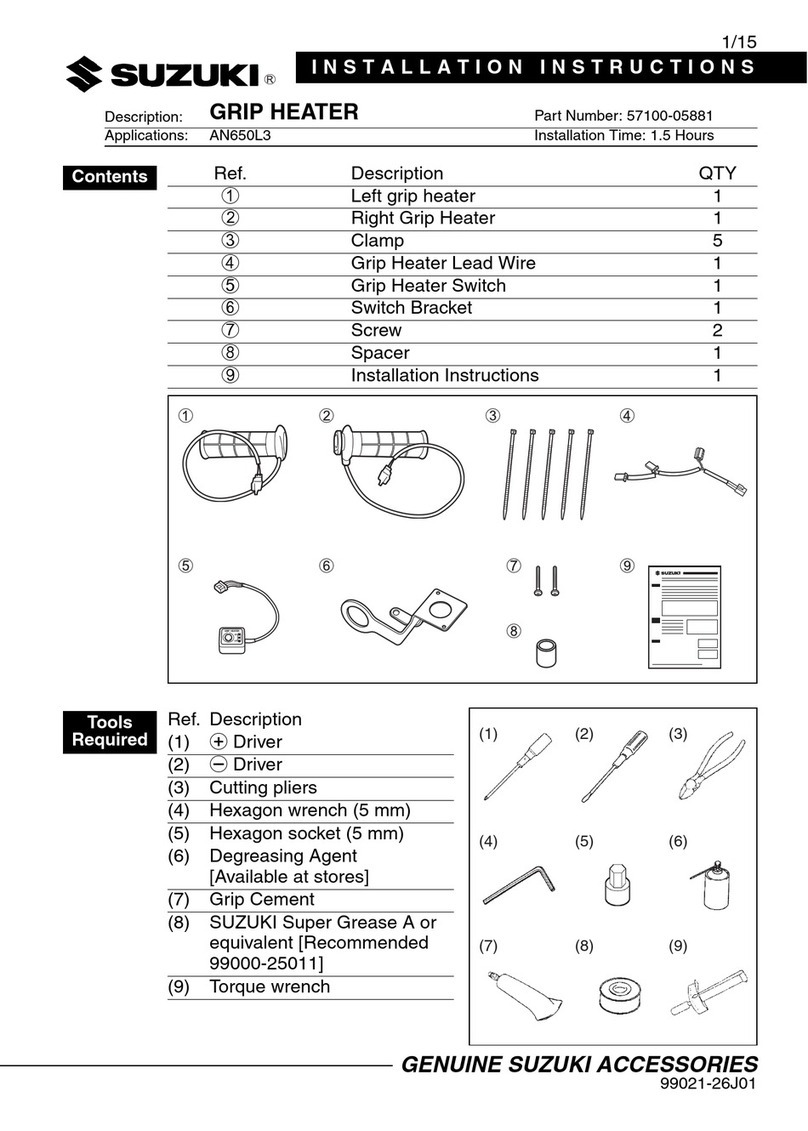

HUB & CLUTCH PACK

INSTALLATION

6. Install the new center clutch hub on top of the

OEM thrust washer.

NOTE: Rekluse has determined that some models

have slight variance between the center hub and

the main shaft. If your Rekluse center hub seems to

be too tight to fit on the main shaft please follow

these steps:

1. Pre-heat your oven to 200°F (94°C).

2. Using appropriate hot part handling protective

gear, place your center hub in the oven for 10

minutes.

3. Using appropriate hot part handling protective

gear, remove the center hub from the oven and

immediately install on to main shaft.

4. Wait until the center hub has completely cooled.

5. Resume installation at step 6.

This installation process will ensure appropriate

center hub fitment.

7. Torque the nut to 50 ft-lb (70 N-m). Bend both

tabs of the lock washer up.DO NOT OVER

TORQUE, or the clutch will drag and damage

may occur.

8. Install the new clutch pack.

NOTE: The first plate installed is the 0.040”

Rekluse Steel Plate. Proceed to install the rest

of the clutch pack alternating frictions (6x) and

remaining drive plates (6x).

NOTE: Some OEM Baskets have “half-slots” at

the top of the basket tangs. Rekluse products

require that all friction disks, including EXP

disk, are seated into the MAIN (deeper)

basket slots.