BestRest Products PegPacker User manual

BestRest Products, LLC

www.bestrestproducts.com 6908 - 220th St. SW (425) 673-1023

info@bestrestproducts.com Mountlake Terrace, WA 98043 fax (425) 673-0502

PegPacker™

Auxiliary Fluid Carrying System for BMW

F800GS, R1100GS, R1150GS, R1200GS.

For Solo Riding ONLY

Thank you for purchasing a BestRest Peg-

Packer™. We truly appreciate every order. If

you have problems with the installation

please call us at the number above or send

us an email. May the Lord God bless you,

watch over you, and keep you safe as you

travel the world on your motorcycling adven-

tures.

David & Judy Petersen

Safety & Fuel Hazard Warnings

Please read these warnings.

They’re for your safety and

they’re very important.

Installing this product incorrectly could result

in a fire or explosion leading to serious bodily

injury or death to you or others.

Using this product other than as described

and approved by BestRest could result in a

fire hazard leading to serious bodily injury or

death to you or others.

Carrying flammable or explosive fluids exter-

nally on any vehicle presents an inherent

safety hazard. The only truly safe method of

carrying fuel is in your vehicle fuel tank.

Carry external fuel only when you anticipate

conditions where you won’t be able to get

gasoline through normal sources.

As soon as your vehicle fuel tank level has

been consumed, transfer fuel from the Peg-

Packer™to your vehicle fuel tank.

In the event of a collision or tip-over, exter-

nally mounted containers may leak, burst,

vent, or otherwise spill their contents. This

may result in a fire hazard leading to serious

bodily injury or death to you or others.

If the PegPacker™is mounted so that it’s

wider than your panniers, the Blitz®container

could be torn from it’s mounts and could spill

its contents. The Blitz®container is not abra-

sion resistant. If it contacts the road surface

the container may spill its contents. This may

result in a fire hazard leading to serious bod-

ily injury or death to you or others.

This product is designed for “off road use

only”. If you choose to use the PegPacker™

on the streets, you are doing so completely at

your own risk.

Read and follow all the safety warnings on

the Blitz®container. Read the colored sticker

on the end of the container, and read the

embossed warnings on the side of the con-

tainer.

When refilling the Blitz®container, place it on

the ground to prevent static charge and

sparking that may result in a fire or explosion

hazard. Read and follow the safety warnings

on the service station fuel pump.

Read all of the instructions before you begin.

If you don’t have proper tools or lack me-

chanical experience, DO NOT PROCEED.

Take the PegPacker™to a qualified me-

chanic for installation.

If you intend to use the container for potable

water, clean the inside with a dish detergent

solution and/or disinfectant. Mark the con-

tainer clearly so it doesn’t get mixed up with a

fuel container. Don’t ever put fuel in a con-

tainer intended for carrying water. Once

you’ve put fuel in a container, it can NEVER

AGAIN be used to carry potable water! Mark

water containers with white paint, or wrap

white tape around the handle so you don’t

accidentally mix water and fuel.

The PegPacker™is for SOLO riding only. It

should never be used when carrying a pas-

senger.

Failure to properly secure the nylon straps

could result in the container falling off the

motorcycle, resulting in a fire hazard leading

to serious bodily injury or death to you or

others.

Failure to tighten the nozzle may cause fuel

leakage and a fire hazard leading to serious

bodily injury or death to you or others.

Do not overfill the Blitz®containers. Leave

plenty of room in the container for expansion

of fuel. Hot weather will cause the gasoline

to expand, which may cause the nozzle to

leak. Allow for expansion by leaving an air

space at the top. The Blitz®container has an

embossed “SAFE FILL LEVEL”. Do not ex-

ceed this mark.

When opening a Blitz®nozzle, do so slowly to

allow vapors to safely escape. If you open

the nozzle too quickly, the fuel may spray

outward and cause a fire hazard leading to

serious bodily injury or death to you or others.

Do not smoke when you are opening, refill-

ing, mounting, or demounting the Peg-

Packer™. Keep the Blitz®container away

from any spark, flame, or other ignition

source.

Yeah, we know, these are dire warnings, full

of doom and gloom. We don’t mean to

frighten you, but we do want you to clearly

understand the risks involved when you carry

fuel externally. Use common sense.

BestRest assumes no responsibility for any

damages or injuries that may occur as from

using this product. Simply stated, you’re us-

ing this product at your own risk. Your legal

rights may vary from state to state, but if

you’re not willing to assume full and complete

personal liability for the safe and proper use

of this product, you shouldn’t be using it.

Return the product to BestRest for a refund.

Refer to the return policy slip attached to your

sales invoice for return authorization details.

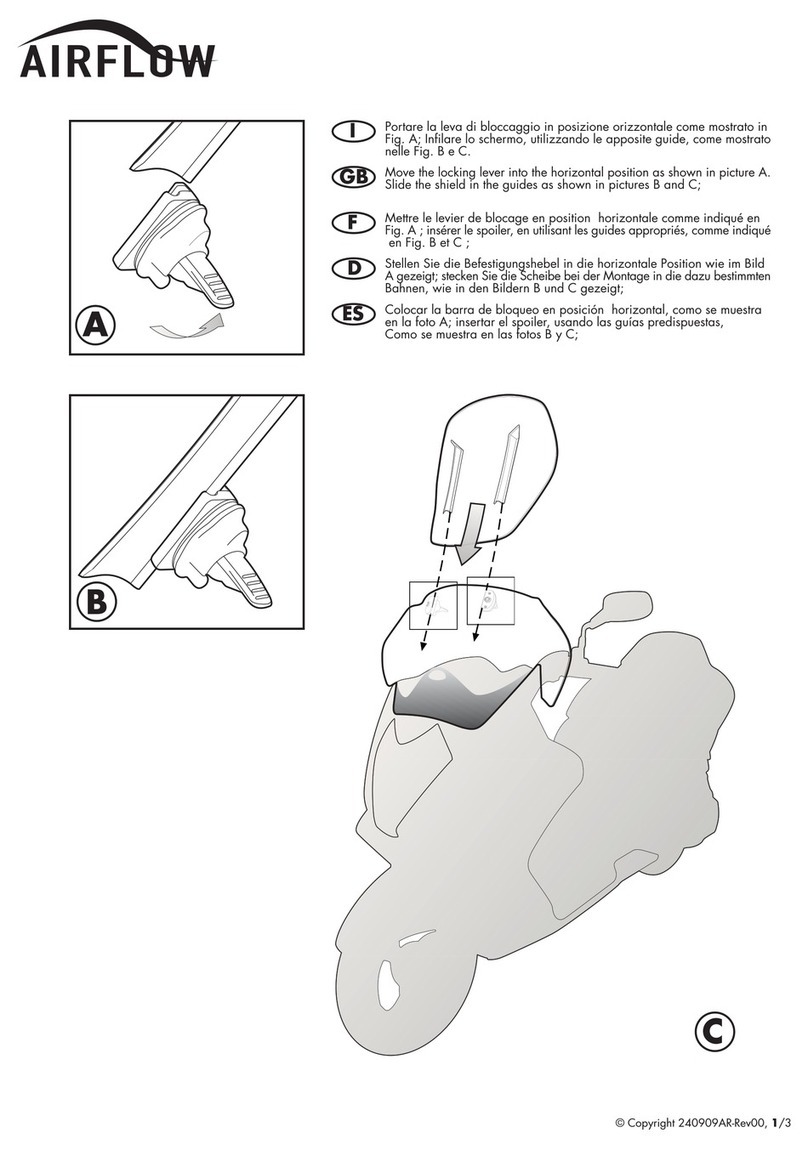

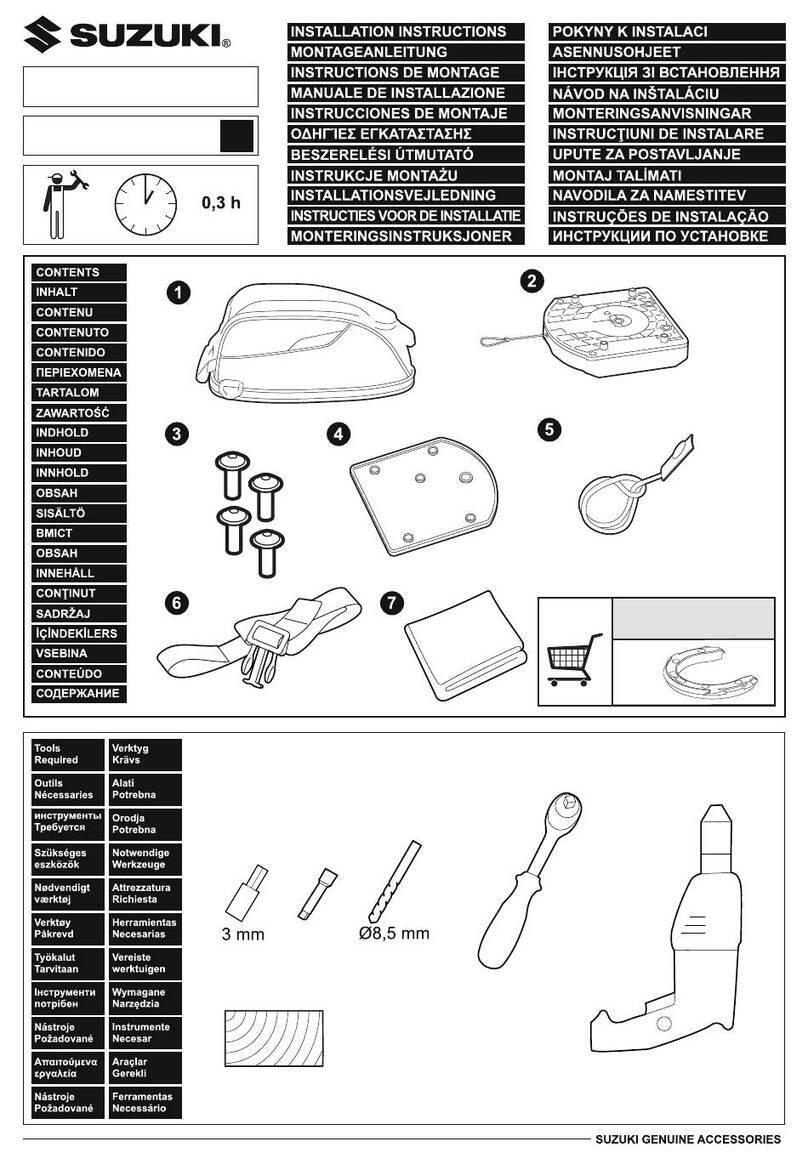

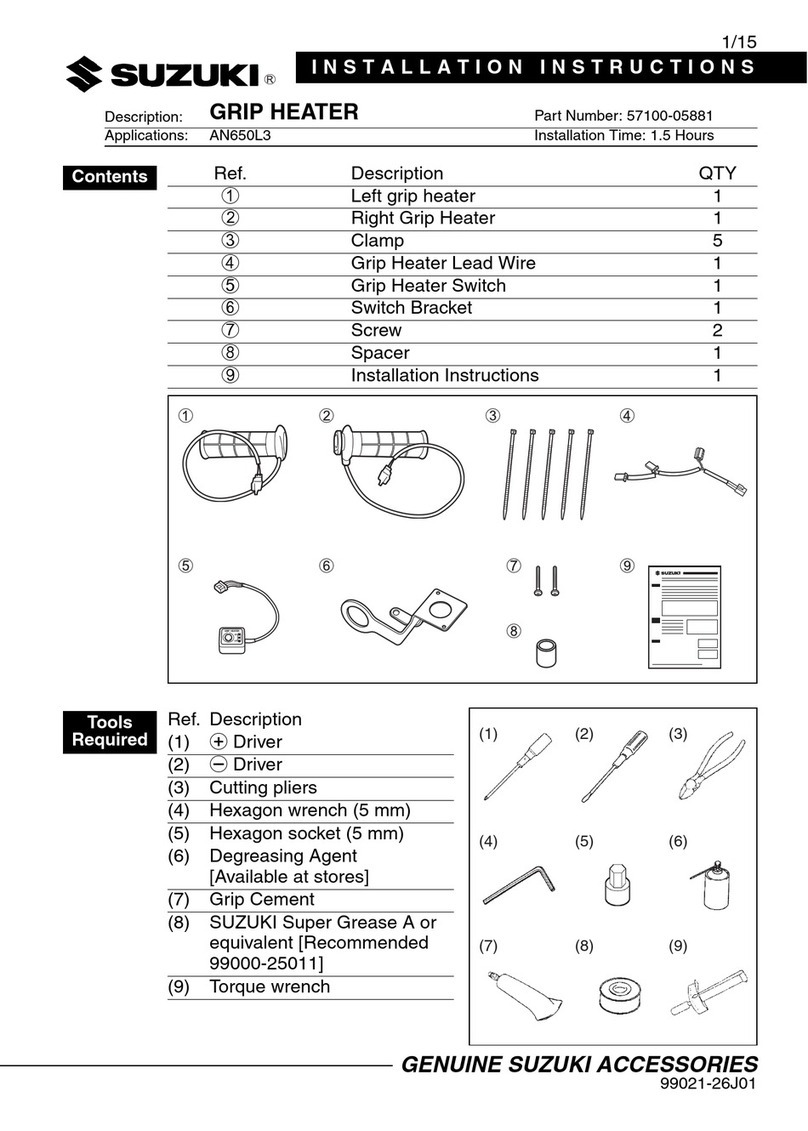

Installation

Please read ALL of the instructions before

you begin. You’ll be glad you did.

Tools needed for installation:

10mm box wrench(s)

10mm socket(s)

5mm hex key wrench

File or rasp

Cordless drill and ¼” drill bit

Fine tipped marker

Blue (semi-permanent) thread compound

The PegPacker™comes in 1 or 2 gallon

sizes. Installation of either size is identical.

The PegPacker™can be mounted on the left

or right side of the motorcycle. The alumi-

num shelf has curved slots to allow rotation of

the shelf to accommodate the geometry of a

motorcycle’s passenger footpeg bracket.

There are minor differences between mount-

ing the PegPacker™on the F800GS, and

mounting on other. We’ll cover those differ-

ences in the text.

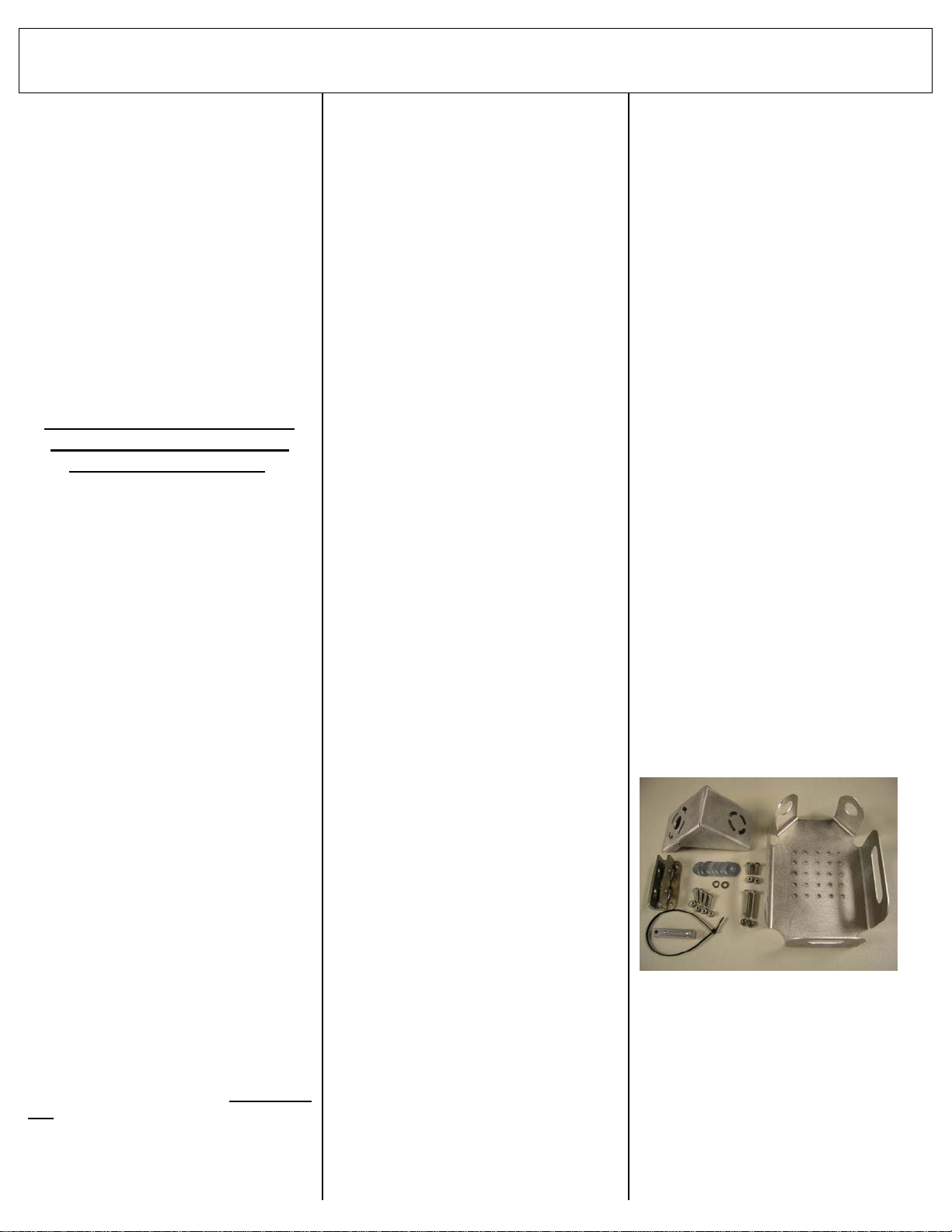

Sort out the parts and identify them.

At upper left is the aluminum shelf.

At far left is the stainless bracket

At lower left is the F800GS tension bar

(not needed for BMW 1100/1150/1200GS)

A ziptie encircles the tension bar

At right is the aluminum Blitz®carrier

(nylon straps not shown)

Other hardware included:

2

2-6x16 hex head screws

2-6x40 hex head screws

4-6x16 button head screws

2-6mm flat nuts

6-6mm nylon locknuts

2-small washers

11-large flat washers

2-rubber caps (not shown in photo)

1-rubber sheet (not shown in photo)

The PegPacker™can be mounted in a HIGH

or LOW position, depending on your needs.

That’s why the stainless bracket has 2 large

holes for the footpeg pivot pin, and 3 small

holes with threaded fittings. For 1-gallon

containers we prefer to mount them in the

HIGH position, for 2-gallon containers we use

the LOW position.

Remove the passenger footpeg. Pull the

cotter pin and washer (or remove the spring

circlip), and then pull the pivot pin holding the

footpeg in place. Push the footpeg inward to

release any tension on the pin.

Temporarily fit the stainless bracket in place

between the two flanges of the welded foot-

peg mount. Reinsert the pin to hold the

bracket in place. In this condition the bracket

is loose and would “flop” or rattle if there

wasn’t some method of providing tension for

the bracket. We have a clever way of solving

that problem.

Here’s a cross section of the system, looking

down from the top of the motorcycle.

The footpeg pin holds the stainless bracket in

place on the welded footpeg bracket. The

long screws hold the aluminum shelf to the

stainless bracket, AND the ends of the

screws also push against the aluminum

block. This forces the stainless bracket into

tension against footpeg pin. The flat nut acts

as a “jamb-nut” which tightens the aluminum

shelf against the stainless bracket, and also

keeps the system from loosening due to vi-

bration. Simple, huh? It works.

The aluminum block has two countersunk

holes to receive the ends of the 40mm

screws, to keep the block from moving. The

other thru-hole is for a zip tie so you can se-

cure the aluminum block to the motorcycle

and prevent loss.

R1100GS-R1150GS-R1200GS, there is no

need to use the machined aluminum block.

Instead the ends of the screws will push

against the inside of the welded footpeg

bracket. See the BIG GS installation section

on page 5.

For the F800GS, temporarily fit the machined

aluminum block in the footpeg bracket and fit

the footpeg pivot pin in place.

If the pin and aluminum bar won’t fit, you can

file a small notch in the bar, in the middle

between the two countersunk holes. You

won’t need to remove much material, just

enough so the pin will fit.

Thread the 2 flat nuts onto the long screws,

followed by a small flat washer and finally a

large washer. Keep the nuts up near the

heads of the screws.

The sequence of nuts and washers is very

important. Please pay close attention.

Fit the two screws into two holes of the alu-

minum shelf. You’ll be working with the

smaller series of slots. Hold the shelf up to

the footpeg bracket and get a general idea of

the angles involved, then select the two holes

that give you a mounting position that pro-

vides a level surface for the Blitz®container.

Place the stainless bracket on the aluminum

shelf and thread the two screws into the

LOWER fittings of the stainless bracket.

Thread the screws about halfway into the

stainless bracket, keeping the nuts up against

the heads of the screws.

Then place the stainless bracket in motorcy-

cle welded footpeg bracket, and insert the pin

thru all 4 holes.

If you’re mounting an F800GS system, make

sure the aluminum block is in place. The

bottom of the block should be even with the

bottom of the stainless bracket, and the ends

of the screws should penetrate into the coun-

tersunk holes.

Before you go any further, reinstall the

washer and cotter pin in the end of the foot-

Motorcycle frame and welded footpeg U-bracket

Footpeg pin

Stainless bracket w/threaded fittings

A

luminum block

(F800GS only)

6x40 screw

Flat nut

Small washer

La

r

ge washe

r

A

luminum shelf

File here

A

pply blue thread locking compound to the

upper ½” of the screws. Do NOT use red

com

p

ounds.

3

peg pin. If you don’t do this now it will be

harder to do when the pin is under tension.

Slip the zip-tie thru the hole in the aluminum

bar, and secure the bar to the footpeg frame

of the motorcycle.

As you tighten the two long screws, keep

their length about the same, in other words

tighten them equally. As they tighten they will

bring tension against the aluminum block, the

footpeg pin, and the stainless bracket.

The aluminum block should be parallel to the

stainless bracket, as shown in this photo.

As you tighten the long bolts, the tension

between the parts will increase and the

stainless bracket will become rigid in relation

to the welded footpeg bracket. Tighten the

bolts gently but firmly. Don’t over-tighten or

strip the threads. Keep the nuts up against

the heads of the screws,

Until now, the aluminum shelf has been free

to rotate on the circular holes. Adjust the

shelf so the top surface is level to the ground,

and tighten the jamb-nuts so the shelf can no

longer rotate. The shelf should be tight and

rigid at this point.

The stainless bracket has 4 holes, one in

each corner. The purpose of these holes is

to receive a “dead-man” screw. This screw

locks the shelf to the stainless bracket, pre-

vents rotation of the shelf on the bracket,

provides an additional fastening point, and

improves stability.

From the back of the stainless bracket, mark

the hole on the back of the shelf. Remove

the shelf and drill the hole, then refit the shelf

and place a short screw thru the hole.

Place a large flat washer on a 6x16 screw,

pass it thru the shelf and thru the stainless

bracket, and a nylon locknut on the end.

The above photo shows the dead-man screw

on an F800GS with the shelf in the LOW po-

sition.

When mounting the shelf in the HIGH posi-

tion, the dead-man screw might not have a

good drilling point so it might not be usable.

R1100GS, R1150GS, and R1200GS geome-

tries work well with the dead-man screw. We

strongly encourage using this option.

Mounting the shelf in the HIGH position.

Some riders will want to mount the Peg-

Packer™in the highest position. This maxi-

mizes leg clearance in the event you’re pad-

dling thru sand or mud.

Fit the stainless bracket to the welded foot-

peg bracket, using the footpeg pivot pin.

Fit the shelf to the UPPER two holes of the

stainless bracket.

Place a short screw (with a large flat washer

on it), thru the UPPER rounded hole of the

shelf, and thread it into the upper threaded

fitting of the stainless bracket.

Place one long screw (with flat nut, small

washer, and large washer as shown in the

earlier photos) thru the middle threaded hole

of the stainless bracket.

Place the second long screw (with flat nut,

small washer, and large washer as shown in

the earlier photos) thru the lower threaded

hole of the stainless bracket.

Now fit the stainless bracket onto the welded

footpeg bracket, and fit the footpeg pivot pin

thru all 4 holes of the brackets.

If you’re mounting an F800GS, use the ma-

chined aluminum block as described above.

Follow those procedures carefully.

If you’re mounting an R1100-1150-1200, skip

the aluminum block. It’s not needed. The

ends of the long screws will contact the

welded footpeg bracket and push against it to

providing tensioning.

Tighten the two long screws evenly until you

achieve tension between the stainless

bracket and the welded footpeg bracket.

Adjust the angle of the aluminum shelf to

achieve a level surface for the Blitz®.

Tighten the jamb-nuts of the two longer bolts,

and tighten the upper short bolt. The shelf

should be in tension.

Once the screws and jamb-nuts are tight, fit a

rubber cap over the ends of the screws. This

finishes off the “look”, protects the screws,

and protects your leg.

Still awake? Keep reading.

Mounting the Blitz®carrier to the shelf.

Now you can plan how you’ll fit the aluminum

Blitz®carrier to the shelf. Place the Blitz®

container in the aluminum carrier and set

them on the shelf. Rotate and consider how

the Blitz®can best be mounted, so that it’s as

close to the motorcycle as possible, and as

far to the rear as possible to give you the

maximum leg clearance.

IMPORTANT NOTE: For structural and

safety reasons it’s important to maximize the

amount of carrier that is resting on the shelf

below. At least ½ of the carrier should be

resting fully on the shelf. The photos below

show different configurations, each of which

places the carrier securely on the shelf.

Short screw at top

With large washer

Long screw

Flat nut

Small washer

Large washer

Long screw

Flat nut

Small washer

Large washer

4

The next series of photos shows possible

installations of a PegPacker™on the right

side of an F800GS. The container is

mounted in the LOW position.

Above is a 1-gallon Blitz®. below a 2-gallon.

The next series of photos shows installation

of a set of 1-gallon PegPackers™on an

F800GS. The Blitz®containers are mounted

in the HIGH position.

Left side above, right side below.

And here’s what it looks like from above:

Depending on your panniers and frame ge-

ometry, rotate the Blitz®carriers to get the

best fit. We prefer to have one corner of the

plastic container touching the pannier. This

small point of contact prevents the system

from vibrating. Use a small piece of foam to

prevent the Blitz®from marring your pannier.

Once you’ve settled on the location of the

Blitz®, hold the aluminum carrier in place and

have a friend pull the plastic Blitz®container

straight up and out of the way - don’t allow

the aluminum carrier to move in relation to

the shelf below.

The bottom of the carrier has a series of

holes that MAY align with the circular holes in

the shelf. With luck you’ll be able to drop 4

screws down thru those holes, but usually

you’ll have to add some holes. We only hit 1

hole and had to drill 3 more holes.

From the underside of the shelf, mark the

carrier with a permanent marker. Remove

the carrier and drill the necessary holes.

NOTE: For structural and safety reasons it’s

EXTREMELY IMPORTANT that the carrier

be secured to the shelf with a minimum of

four (4) screws.

Don’t be limited by the holes we provided –

maximize the “footprint” and get your holes

as wide as possible.

Once your 4 holes are marked and drilled,

replace the carrier on the shelf. Place a large

flat washer on the 4 button head screws, and

drop the screws thru the holes.

On the underside of the shelf, place a large

flat washer on each screw, followed by a ny-

lon locknut.

In the above photo, the lower left washer

needed to be trimmed to fit inside the shelf.

IMPORTANT NOTE: For structural and

safety reasons it’s important to use a large

flat washer on the top and bottom for each

screw!

Tighten the screws and nuts.

To protect the plastic Blitz®container from

damage caused by the raised head of the

button screws, insert the rubber sheet into

the carrier. Trim the sheet as needed.

Reinstall the Blitz®container in the carrier.

Check for proper clearances, and confirm

that the PegPacker™fittings are tight.

4 button head screws w/

large washers

5

Mounting to the BIG GS Series

R1100GS / R1150GS / R1200GS

There are some minor mounting differences

between the F800GS (described in nauseat-

ing detail above), and the BIG GS series.

The footpeg pivot pin is a tight fit. You MAY

find that while you can get the pivot pin into

the top hole of the stainless bracket, it just

won’t fit into the lower holes. This is because

the welds and bends of the footpeg bracket

are hitting the corners of the stainless

bracket, preventing the bracket from fitting

into place.

To correct this issue you can use a rattail file

to slightly enlarge or elongate the pivot pin

holes in the stainless bracket. Don’t file the

holes of the welded footpeg bracket itself.

Alternatively you can file the ends of the

stainless bracket. This drawing shows the

area to file:

Or, elongate this hole slightly. (exaggerated)

It doesn’t take much filing to get the part to fit.

Unlike the F800GS system, the BIG GS sys-

tem relies on only one long screw to provide

tensioning between the welded footpeg

bracket, the pivot pin, and the stainless

bracket.

The lower screw should be fully tightened

until it makes contact with the welded

bracket.

Depending on your motorcycle and the

placement of the welded footpeg bracket, the

lower tensioning screw may not provide full

tension because the jamb-nut is bottomed

between the head of the screw and the small

washer. Rather than using a longer screw,

remove the small flat washer from the long

screw. This will allow the screw to penetrate

further. Keep the large flat washer on the

screw, along with the jamb-nut. Replace the

screw and tighten until the system comes into

tension, then tighten the jamb-nut to prevent

the shelf from rotating.

The upper long screw won’t make contact

with anything at the far end. Thread the

screw in about ¾ of its length, then tighten

the jamb-nut to secure the shelf to the

stainless bracket.

Follow the above instructions regarding

placement of the Blitz® carrier on the shelf.

Here’s photos of the completed system on

the R12GS and R12GSA.

Shelf in place on R12GS, above.

1-gallon Blitz®in place on R12GS, below.

2- gallon Blitz®in place on R12GS, below.

1-gallon Blitz®in place on R12GSA, above.

2-gallon Blitz®in place on R12GSA, below.

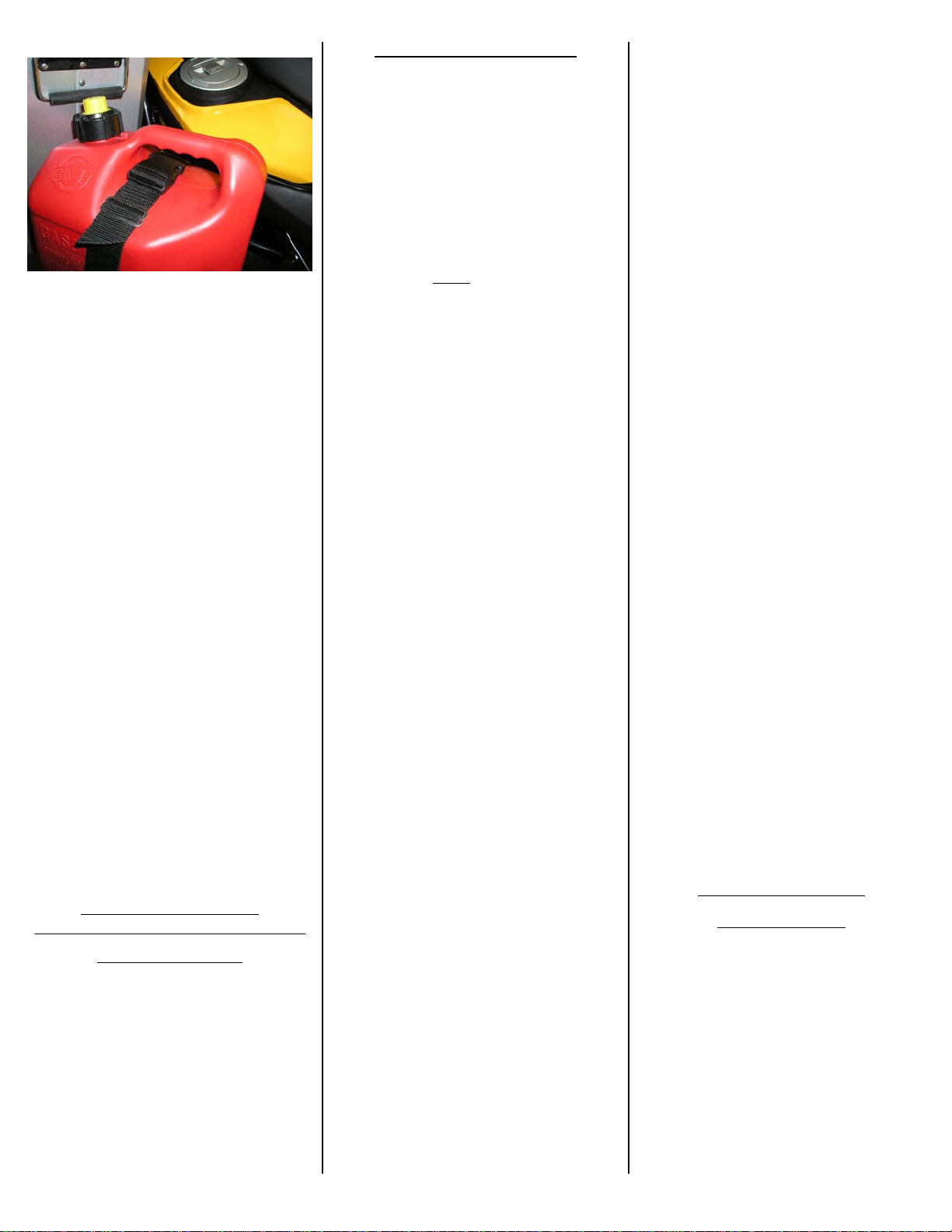

Nylon Straps

Each PegPacker™is supplied with a 2” wide

nylon strapping system. This system is de-

signed to provide a safe and secure method

of securing the Blitz®container to the alumi-

num carrier, while still enabling easy access

when fluids are needed.

This is accomplished by means of metal fig-

ure-8 fittings, and a pinch release nylon buck-

le system. To release the buckle pinch the

two sides until the buckle releases. To se-

cure the buckle, push the ends together until

both tabs CLICK and lock.

The nylon straps are configured by BestRest,

and should not be changed. Should you

need to reconfigure the straps for any reason,

replicate our system without changes. If a

nylon strap is improperly configured it could

result in the Blitz® container coming loose

from the motorcycle, with potentially serious

consequences. See page 1 for the hazards.

6

The nylon strapping system can be adjusted

by moving the straps thru the metal figure-8

fittings.

One of the straps is adjustable at the nylon

buckle; the other one is not. The “male” fit-

ting is fixed and cannot be adjusted. The

“female” fitting can be adjusted by pulling the

strap thru the fitting. To create tension on the

straps, grip the loose end of the strap that

projects from the “female” portion of the

buckle, and pull.

Secure loose ends of the straps by running

them thru the figure-8 fittings. Don’t leave

ends loose or the strap could work itself

loose. Loose straps can constitute a safety

hazard, refer to page 1.

Every time you ride the motorcycle you

should check the straps on the PegPacker™.

Adjust as necessary.

The nylon straps should be inspected on a

daily basis for signs of fatigue, wear, or abra-

sion. Pay special attention to the points

where the straps pass thru and around the

openings in the aluminum Blitz®carrier.

If the straps get cut, become fatigued or are

otherwise damaged the Blitz®container could

fall from the motorcycle. Refer to page 1 for

potential hazards.

Visit our online SmugMug photo repository to

view larger images of the photos shown in

these instructions:

www.bestrest.smugmug.com

Alternative Applications

The PegPacker™can also be used as a

camera-mounting platform. The series of

rounded holes on the upper shelf will fit with a

RAM®ball mount. Instead of fitting a Blitz®

carrier, install a RAM®mount and use the

system to hold your video camera.

More Safety and Legal Notices

Off-road travel and/or riding on washboard

surfaces will place high stress levels on the

mounting system. Off road travel can lead to

premature metal fatigue and/or structural

failure. Likewise, a tip-over or other collision

can cause a similar failure.

To reduce the chance of metal fatigue, do not

allow the PegPacker™to vibrate or oscillate.

You can reduce this vibration by running a

second strap (not included) thru the handle of

the plastic container and around a frame

member, then gently cinching the strap to

take out any free movement. Normally this

second strap is not needed, but we mention it

for informational purposes.

If structural failure of the mounting system

occurs, the bracket and container could fall

beneath the wheel, interfere with control of

the motorcycle, and result in handling or con-

trol problems.

It‘s very important to check the brackets on a

daily basis for signs damage, metal fatigue,

and/or loose or missing hardware. If these

are discovered you should immediately re-

move the PegPacker™from service until

repairs can be made.

Do not proceed with product installation

unless you are qualified to complete the in-

stallation in a safe fashion and as described

herein. Do not use these products unless

you have read all instructions and understand

how these products work and what limita-

tions, if any, they may have.

It is the responsibility of the Consumer to

evaluate the suitability of these products for

personal use. Consumers must evaluate

whether these products meet their needs and

whether these products can be mounted and

used in a safe fashion. The Consumer ac-

cepts full and complete responsibility for se-

lection of products and for mounting and

maintenance of these products. The Con-

sumer agrees to follow and abide by all in-

structions, warnings, recommendations, or

other information supplied or published by

BestRest Products.

It is the Consumer's responsibility to inspect

all screws, fasteners, straps, nozzles, and

other fittings on a daily basis, tighten or re-

place them as necessary, and to regularly

inspect the entire system for signs of missing

parts, excessive wear, metal fatigue, or im-

minent failure. Should any of these be ob-

served the assembly should be removed from

the motorcycle and not used until inspected

and repaired by BestRest.

BestRest Products, it's employees, agents,

and owners assume no liability whatsoever

for property damage, personal injury or other

losses resulting from the Purchaser's failure

to properly maintain the products, for unau-

thorized modifications of any kind, for use of

unauthorized parts (including bushings,

screws, pins, straps or other fasteners), or for

use of any BestRest Product in a fashion not

intended by BestRest or described as a sug-

gested application in BestRest literature.

Because installation of these products is

done by others outside our control, we cannot

assume any liability or responsibility whatso-

ever for improper or unsafe installation, or

installation which is contrary to published

instructions, for products that are improperly

secured or maintained, or that are improperly

tightened or otherwise secured, or which are

otherwise improper fitted to the motorcycle.

Only authorized, and approved replacement

parts, assemblies, nuts, washers, screws,

fasteners or fittings may be used when

mounting, installing, or repairing any

BestRest Product. Authorized replacement

parts may be purchased only from BestRest

Products. Parts from other sources or ven-

dors are not covered under warranty and will

void any Consumer claims against BestRest

or others. Any use, modifications, or applica-

tions of any BestRest Product, other than

those authorized by us in writing, are specifi-

cally prohibited.

BestRest products are warranty against de-

fects in workmanship or materials for 90 days

after purchase by the original retail customer.

PegPackers™that have been modified by

the consumer are not covered under war-

ranty.

Warranty does not cover damage caused by

collision or accident.

PegPackers™that have been drilled or

mounted are not eligible for return.

Blitz®containers that have been filled with

any type of fluids, including fuel or water, are

not eligible for return.

For legal disclosures and a description of our

warranty, please refer to our website:

www.bestrestproducts.com

www.pegpacker.com

“PegPacker” is a trademark of BestRest Pro-

ducs, LLC

“Blitz” is a registered trademark of Blitz USA.

The Blitz®fuel container nozzle is covered

under US Patent #D434,328.

©2008 BestRest Products LLC. All rights

reserved.

Table of contents

Other BestRest Products Motorcycle Accessories manuals