Revision: 24/03/2011 Page 10of17

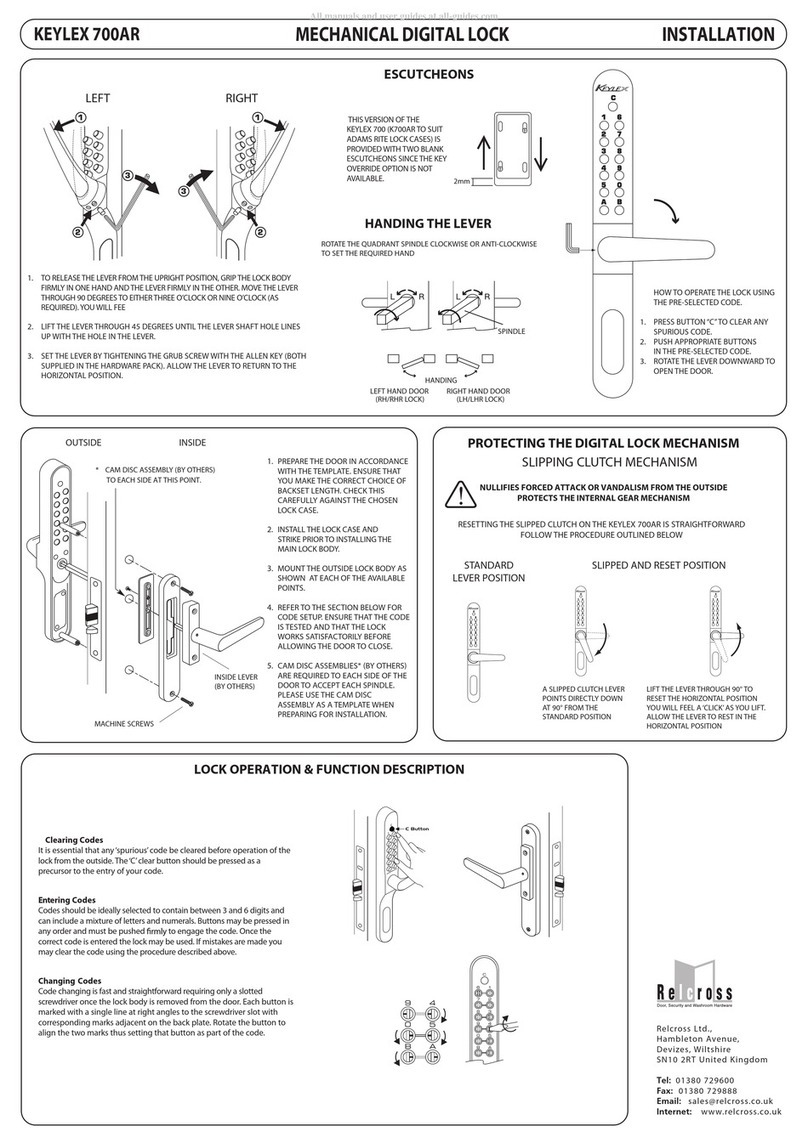

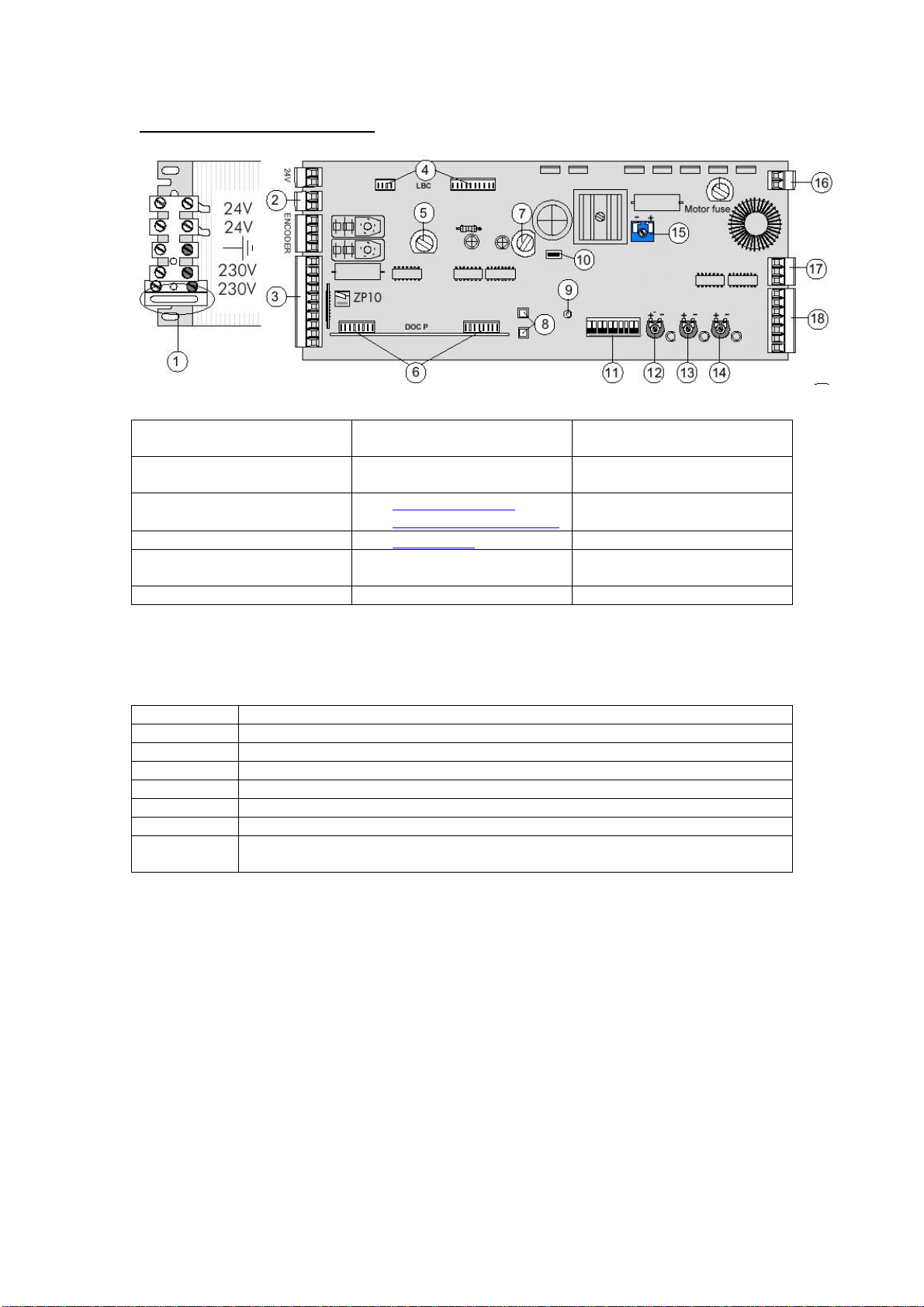

ZP 10 Motherboard Layout

Keytodrawing

1. Fuse -240VAC supply 2. 24 VDC Backup battery

connection 3. 10 wayconnector

4. LBP7 connection for

7032board 5. Fuse 6. DOC PConnector

7. Fuse 8. Chiursura (close)

Apertura (Open)buttons 9. LED

10.Reset Switch 11. Dipswitches 12.VEL – Doorspeed

13.RAL– Slowdown speed 14.TCA– Time at open

position 2-16 seconds 15.Forza– MotorTorque

16.Motorconnections 17.To slave unit(ifused) 18.7wayconnector

Please note: slight variationsoccur, more recent ZP10 boardshavea motorfuse and trimmersare

in slightlydifferent locationsin that items12 13 &14 are adjacent to eachother.

10 wayconnector pinouts(see item3):

Pins Description

10 &11 24 VACaccessorypower-15Wmaximum(600 mAapprox)

1 &2 Shorted out assupplied – use withswitch foremergencyorkeySto disable

2 &R1 Normallyopen contactsforpush button and/orPIR motion detector

2 &R2 Normallyopen contactsforsafetysensoropeningside (set Dipswitch 9 to on)

2 &R3 Not used

2 &M Normallyopen contacts-can be used with manualpush button

2 &C1 Normallyclosed contactsofsafetysensoron closing side – re-open on

closingcycle when contactsopen (set Dipswitch8 to off)

Switching contacts are all voltfree, normallyopenswitches

Amanualpush button orotherPIRwith normallyopen contactsisconnected across pins2 &R1

Safetysensor–opening side setdipswitch9toON, connectsensornormallyopencontact

connectedacross pins2&R2. The operatorwillhalton the opening cycleandcontinue oncethe

objectorperson hasmoved. Acamswitchtoinhibitthe safetysensors at the closed position will

prevent unnecessaryactivation

Safetysensor–closing side set dipswitch8to OFF &safetysensornormallyclosed contact

connectedacross pins2&C1. The operatorwillstop&re-open,remaining intheopenposition–

the redLEDonZP10 boardwill illuminatewhilstthe circuitbetween 2&C1 isopen &theoperator

willnot close.

Providingtheloaddoesnotexceed15Watts(approx600mA)the sensors maybe powered from

the 24VACaccessoryconnection – caution, overload willcausedamage.