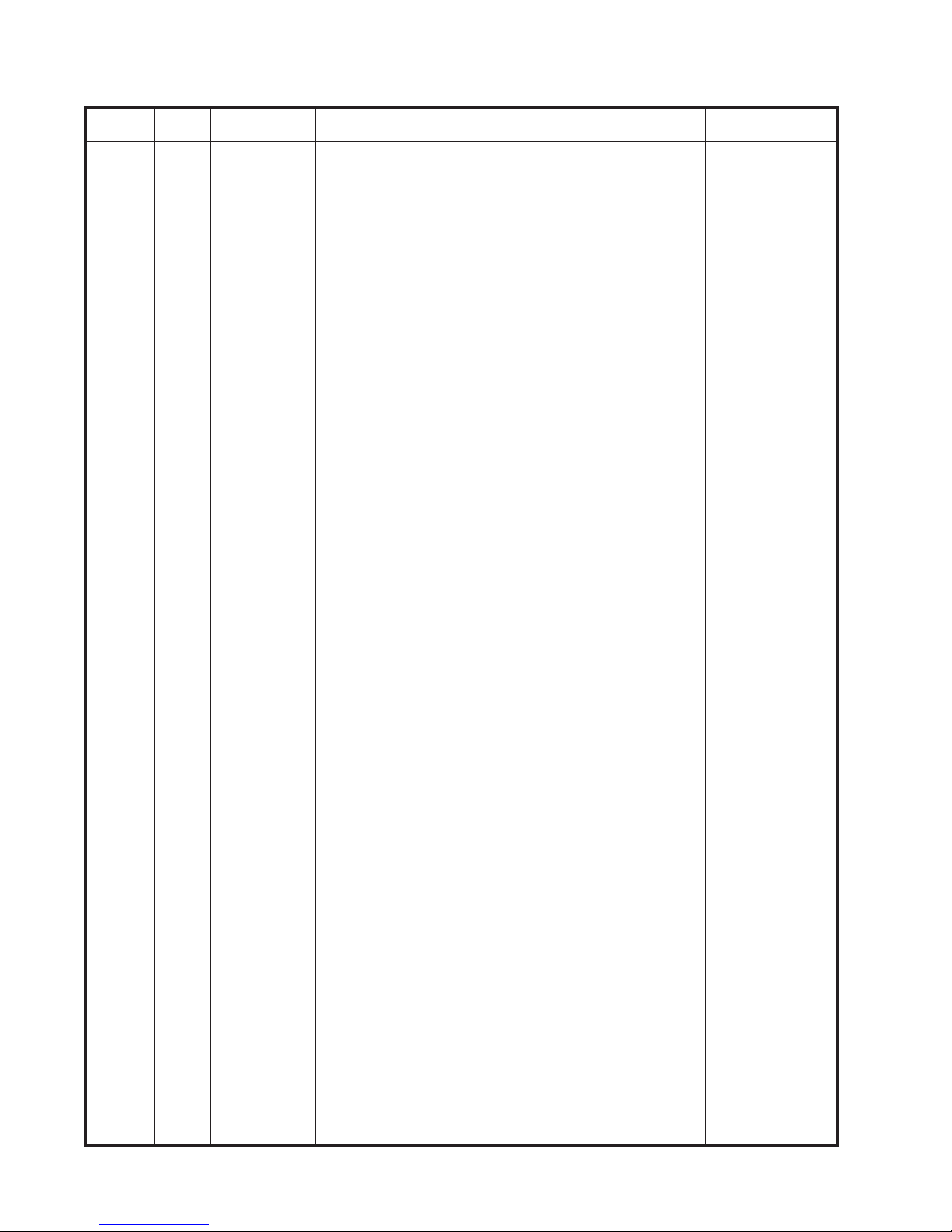

10

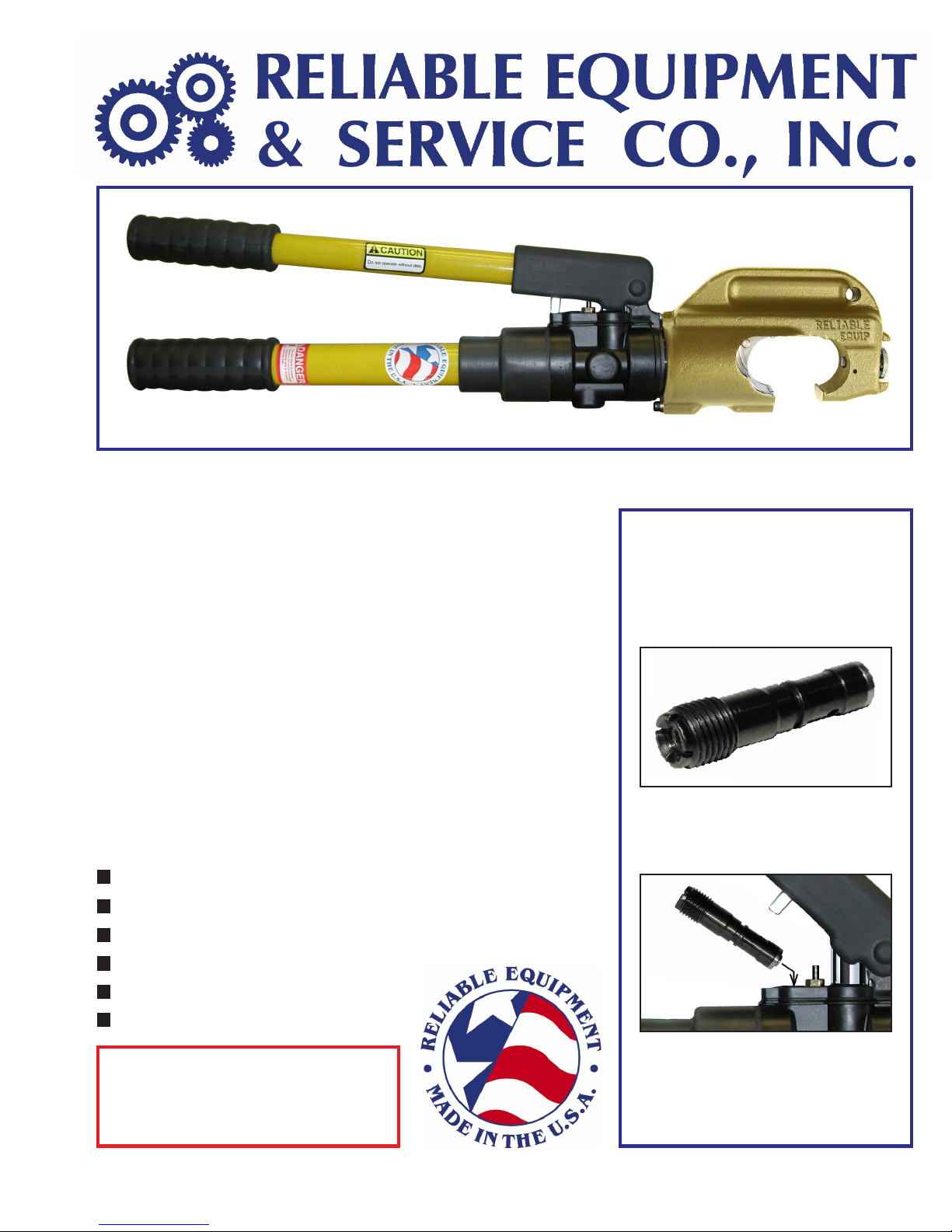

MAN. HYD. CRIMPING HANDLE PARTS LIST

ITEM QTY PART NO DESCRIPTION DRAWING #

1 1 R19101 BODY, MACHINED 2

7 1 R18007 RETURN SPRING 2

8 1 R18008 CAP, SPRING 2

9 1 R18009 SNAP RING, CAP STOP 2

10 1 R19010 REAR STOP 1

12 2 R18012 HARD BALL, 7/32 DIA. 1, 2

13 2 * R18013 O’RING 1, 2

14 2 * R18014 BU RING 1, 2

15 1 R18015 RELEASE PLUNGER 2

16 1 R18016 SPRING, RELEASE 1

17 1 R18017 BRASS NUT 2

18 1 R18018 SIDE PLUG 2

19 1 R18019 PINTLE, SIDE PLUG 2

20 1 R18020 CHECK CAP 1

21 1 R18021 BALL, 3/16, FEED CHK. 1

22 1 R18022 FILTER BODY 1

23 1 R18023 SCREEN, BRASS 1

24 1 R18024 FINGER CLIP 1

25 1 R18025 MOUNT, BODY HANDLE 1

26 1 R18026 RESERVOIR PLUG ASSY, R410-55 1

27 1 R18027 MAGNET, ASSY R410-55 1

28 1 R18028 HANDLE, FIBERGLASS BODY, 430-10HT 1

29 1 R18029 PUMP ARM, FIBERGLASS, 410-30 2

30 1 R18030 SHOULDER HOUSING 2

31 1 R18031 POINTER 2

32 1 R18032 RELEASE FINGER 2

33 4 R18033 BRONZE BUSHINGS 2

34 1 R18034 KNUCKLE 2

35 1 R18035 FAST ADV. PLUG 1

36 1 R18036 SET SCREW, 6-32 X 3/16 2

37 1 R18037 3/32 BALL 2

38 1 R18038 LOWER CHK. SPRG. 1

39 2 R18039 UPPER CHK SPRG. 1

40 1 R28540 PISTON INJECTOR 2