Manual cable marking: pre-termination

161

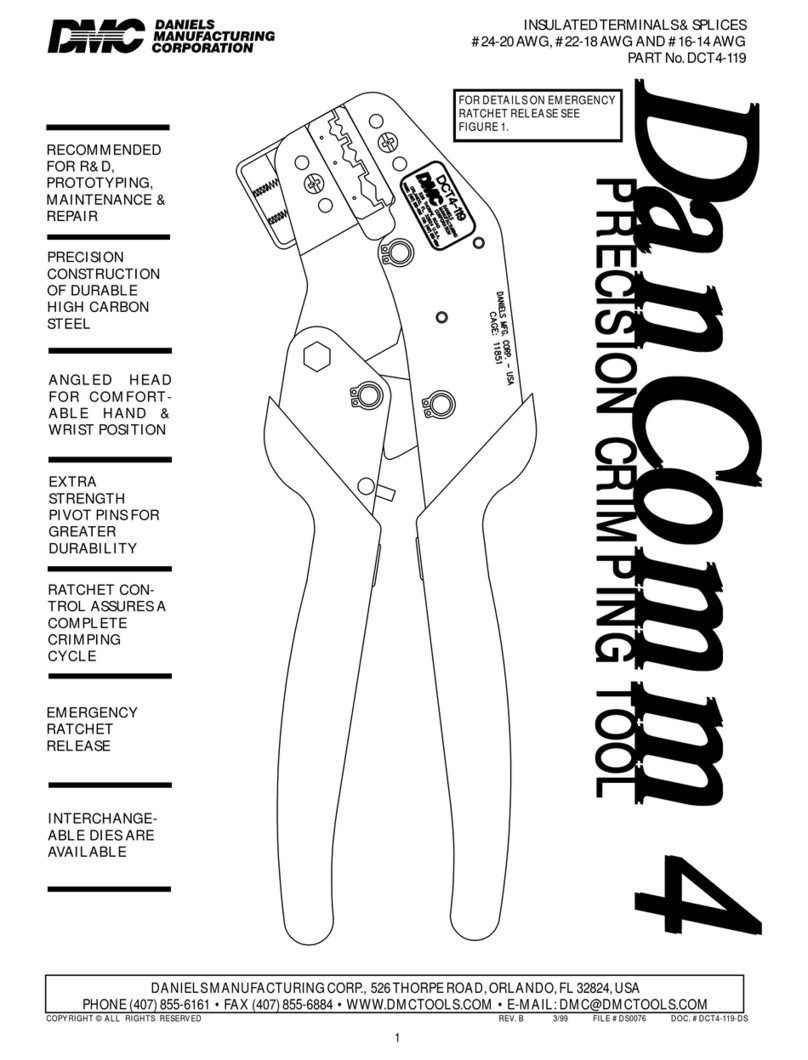

CTT Crimping solutions

AMP

DMC AF8 adjustable crimp tool

AF8 tool

Part number Military part

number

Description

AF8 M22520/1-01 Tool frame

TH1A M22520/1-02 Turret

TH4 M22520/1-03 Turret

TH163 M22520/1-04 Adjustable

positioner

UH2-5 M22520/1-05 Positioner

TP45 M22520/1-06 Positioner

TP85 M22520/1-07 Positioner

TH199S M22520/1-08 Positioner

TP360 M22520/1-09 Positioner

TP365 M22520/1-10 Positioner

TP465 M22520/1-11 Positioner

TH270 M22520/1-12 Positioner

TH285 M22520/1-13 Positioner

TH286 M22520/1-14 Positioner

TP485 M22520/1-15 Positioner

TP513 M22520/1-16 Positioner

TP651 M22520/1-17 Positioner

G125 M22520/3-1 Gage

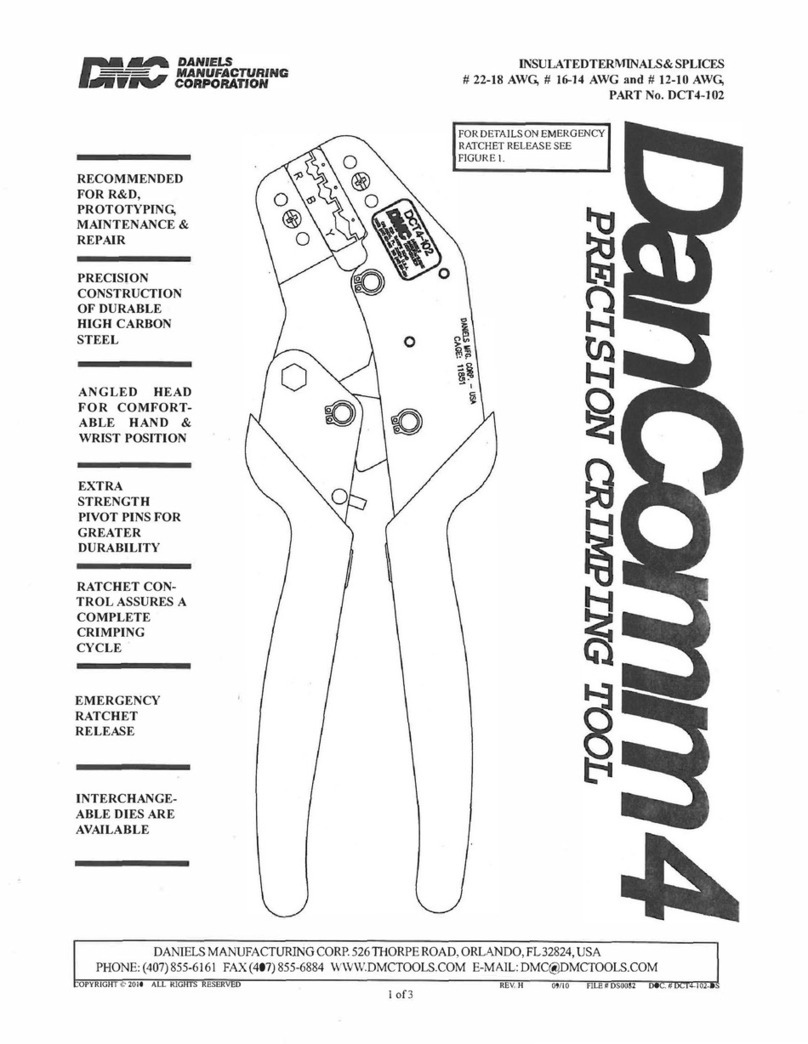

AF8 standard adjustable crimp tool

General information

1. AF8 (M22520/1-01) refers to basic tool without

poisitioner.

2. Wire crimp range 26 to 12 AWG.

3. The tool has a double action ratchet, and cannot be

opened without completing the cycle.

Tool must be in open position whenever positioner is

being installed, removed or released. Damage to turret

head and/or crimp tool may result if this procedure is not

followed.

1. Tool must be in open position.

2. Press positioner trigger latch which releases turret to

indexing position.

3. Place positioner onto retaining ring with alignment pin

in alignment hole.

4. After positioner is seated against retainer ring, tighten

socket head screw with 9/64" hex key.

5. Refer to data plate on positioner. From colour code

column, select the positioner colour that corresponds

with the appropriate part number and size of contact to

be crimped.

6. With tool in open position, rotate until colour coded

insert is in line with the index mark. Press turret until it

snaps in latched position.

7. Refer to data plate. From wire size column, determine

the selector setting that corresponds with the contact

bring used.

8. Remove spring clip from selector knob and rotate until

correct setting is in line with selector mark.

Installation of positioner

1. Insert contact and prepared wire through the indenter

opening into the positioner.

2. Squeeze handles together until ratchet releases.

Handle will return to open position.

Crimping instructions

1. With tool in open position, release turret. Loosen

screws until threads are disengaged from retainer ring

and remove with a straight lifting motion.

Removing positioner

Caution

CONNECT