8

TOOL SPECIFICATIONS

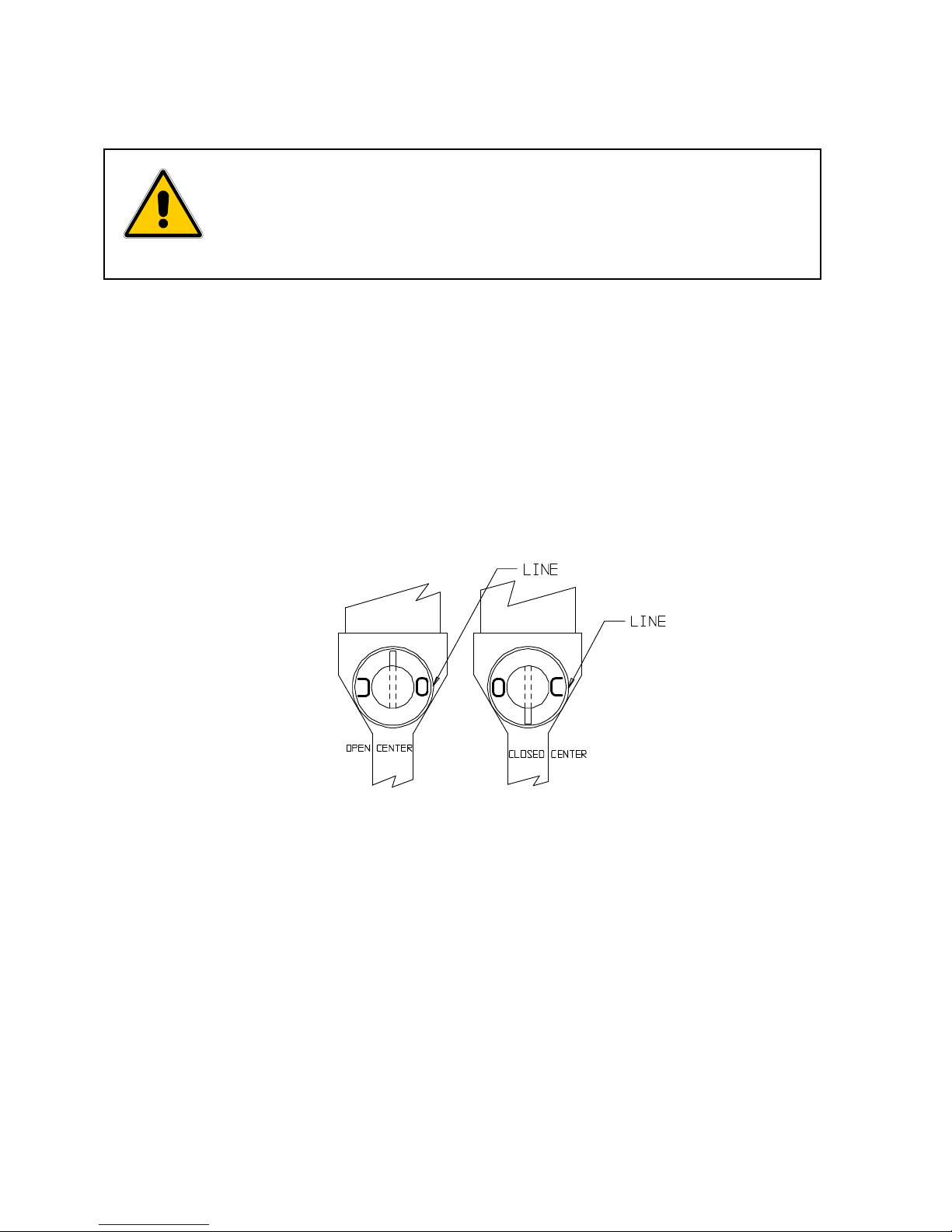

System...........................................................................Open-Center or Closed Center

Overall Length .................................................................................82 inches (202.28 cm)

Handle Width........................................................................................ 7.5 in. (19.05 cm)

Opreating Pressure (Min. - Max.)............ 1,750 psi (121 bar) - 2,000 psi (138 bar)

Flow (Minimum).................................................................................... 4 gpm (15.1 l/min)

Flow (Recommended) ......................................................................... 5 gpm (18.9 l/min)

Flow (Maximum)................................................................................... 6 gpm (22.7 l/min)

Pressure Relief (Maximum) .............................................................2,000 psi (138 bar)

Back Pressure (Maximum).................................................................200 psi (13.8 bar)

Pressure & Return Ports .................................................................................... 3/8 NPT

Weight with Blade................................................................................. 9.3 lbs. (4.0 kg)

Blade Diameter (Maximum) ...................................................................9 in. (22.86 cm)

Arbor (DD type)..................................................... 5/8” x 7/8” (15.88 mm x 22.23 mm)

Blade Rating (Minimum)................................................................................. 5,400 rpm

Cutting Depth........................................................................................... 3.5 in. (89 mm)

HYDRAULIC FLUIDS

All hydraulic fluids that meet these listed specifications or the listed HTMA

specifications may be used for this tool.

@ 100OF (38OC) ............................................................... 140 TO 225 S.U.S.

@ 210OF (99OC) ............................................................ 40 S.U.S. (minimum)

FLASH POINT ........................................................ 340OF min. (170O C min.)

POUR POINT..... ..................................................... -30OF min. (-34OC min.)

These specifications must be strictly adhered to for this tool to function

properly. Any deviation can cause tool damage, severe injury or death.

Use only factory specified parts when repairing and/or replacing.

Severe tool damage or personal injury may occur with non-specified parts.

Always use appropriate blades meeting applicable industrial safety

specifications for the use intended by the manufacturer.

WARNING

Blade must be installed to rotate in the correct direction. Follow the blade manufacturer’s

instructions and refer to the illustration later in this manual.

Inspect blade for wear or damage before installing and before each use. A damaged

blade may break causing a hazard for the operator, other personnel and/or bystanders.

Failure to heed these warnings could result in severe bodily injury or death.