2

Table of Contents

Section Page

Table of Contents ..................................2

Safety Instructions for Miter Saw ...........2

Safety Signal Words ...........................2

Before Using The Saw ........................3

When Installing Or Moving The Miter

Saw ...................................................3

Before Each Use ....................................4

To Reduce The Risk Of Injury From

Jams, Slips Or Thrown Pieces ..........5

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears .......................5

Inspect Your Workpiece .........................6

Whenever Saw Is Running ....................7

Before Leaving The Saw .......................8

Glossary of Terms for Woodworking .....8

Motor Specifications and Electrical

Requirements ....................................9

Power Supply and Motor Specifications ..9

General Electrical Connections ..........9

110-120 Volt, 60 Hz. Tool Information 9

Motor Safety Protection ....................10

Wire Sizes .........................................10

Unpacking and Checking Contents .....10

Tools Needed ...................................10

Unpacking .........................................11

List of Loose Parts ............................11

Assembly .............................................12

Removing or Installing the Blade ......12

Assembling Extensions and Stop Block 13

Assembling Dust Elbow and Dust Bag .14

Getting to Know Your Miter Saw ..........15

Alignment (Adjustments) ......................16

Step One - Checking and Adjusting

Blade Squareness to Fence (Miter

Alignment) .......................................16

Step Two - Bevel Adjustments ..........17

Installing the Throat Plate .................18

Cutting Through Throat Plate ...........18

Mounting The Miter Saw ......................19

Safety Instructions for Basic Saw

Operations .......................................20

Section Page

Before Using The Miter Saw .............20

Before Each Use .............................. 20

To Reduce The Risk Of Injury From

Jams, Slips Or Thrown Pieces ........ 21

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears ....................21

Inspect Your Workpiece ......................22

Whenever Saw Is Running ..................23

Before Leaving The Saw ..................24

Basic Saw Operations ......................... 24

Body and Hand Position ................... 24

Miter Cut ........................................... 25

Bevel Cut .......................................... 25

Compound Cut .................................26

Cutting Bowed Material .................... 26

Workpiece Support ...........................27

Auxiliary Fence ................................. 27

Use and Operation of Extension Bars

and Stop Block ................................28

Cutting Compound Miters .................29

Using Carbide Tipped Blades ..............31

Maintenance and Lubrication ..............31

Maintenance .....................................31

Replacing Carbon Brushes ...............31

Lower Blade Guard ...........................31

Sawdust ............................................32

Lubrication ........................................ 32

RIDGID Recommends the Following

Accessories .....................................32

Recommended Accessories .............32

Prohibited Accessories ..................... 32

Basic Blade Requirements ...............33

Wiring Diagram .................................... 33

Troubleshooting Of Brake By

Qualified Service Person Only ........33

Troubleshooting Guide ........................ 33

Motor ................................................ 33

General ............................................. 34

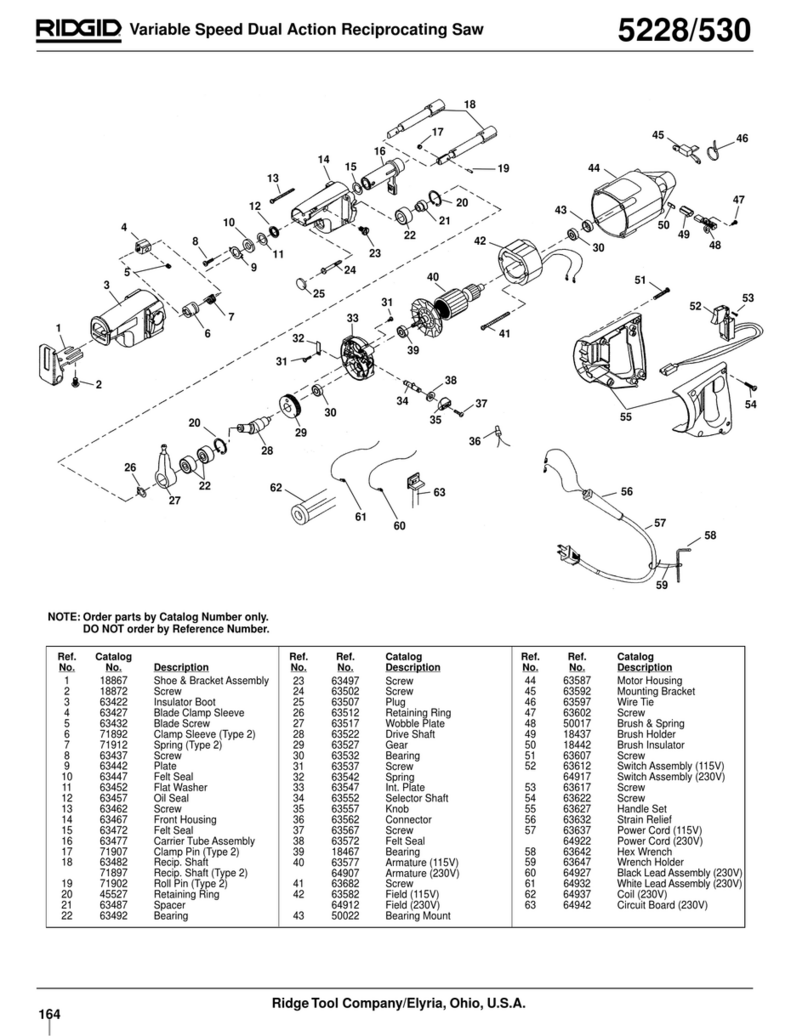

Repair Parts ........................................ 35

Notes ................................................... 42

Safety Instructions for Miter Saw

Safety is a combination of common sense, staying alert and knowing how your miter

saw works. Read this manual to understand this miter saw.

Safety Signal Words

DANGER: If the safety information is not

followed, someone will be seriously

injured or killed.

WARNING: If the safety information is not

followed, someone could be seriously

injured or killed.

CAUTION: If the safety information is not

followed, someone may be injured.