Press AutoStart/Resume Pushbutton –On Control Panel. “Manual Mode.” display shows

up.

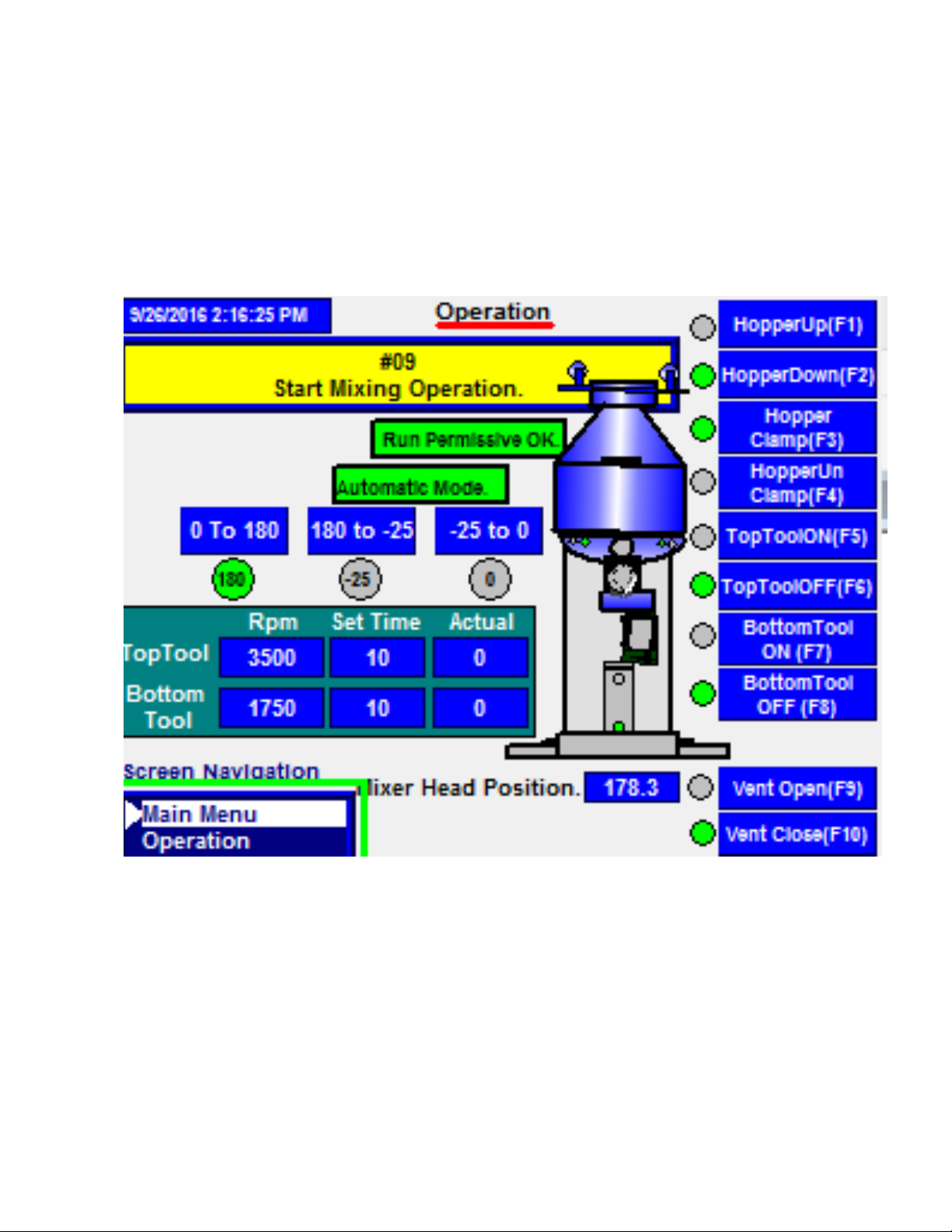

Local Message Display show current steps of operation.

System allows operator to initiate appropriate steps to run a full cycle.

For more detail see Flow Chart: Sequence Operation.

Manual operation can be Paused by pressing “Stop” Pushbutton and resumed by pressing

AutoStart/Resume Pushbutton. Estop can also be use for emergency stop of operation.

Manual Mode Operation Steps

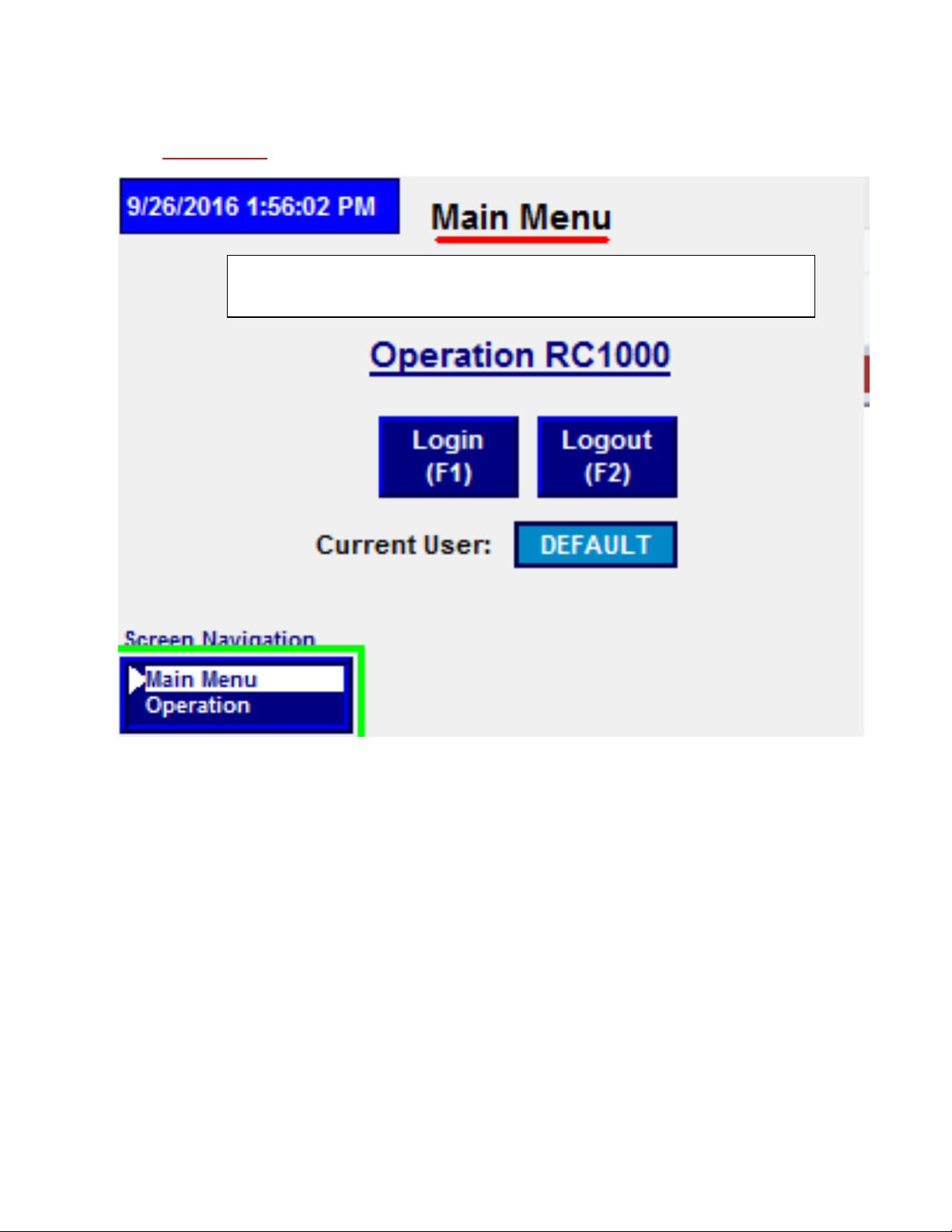

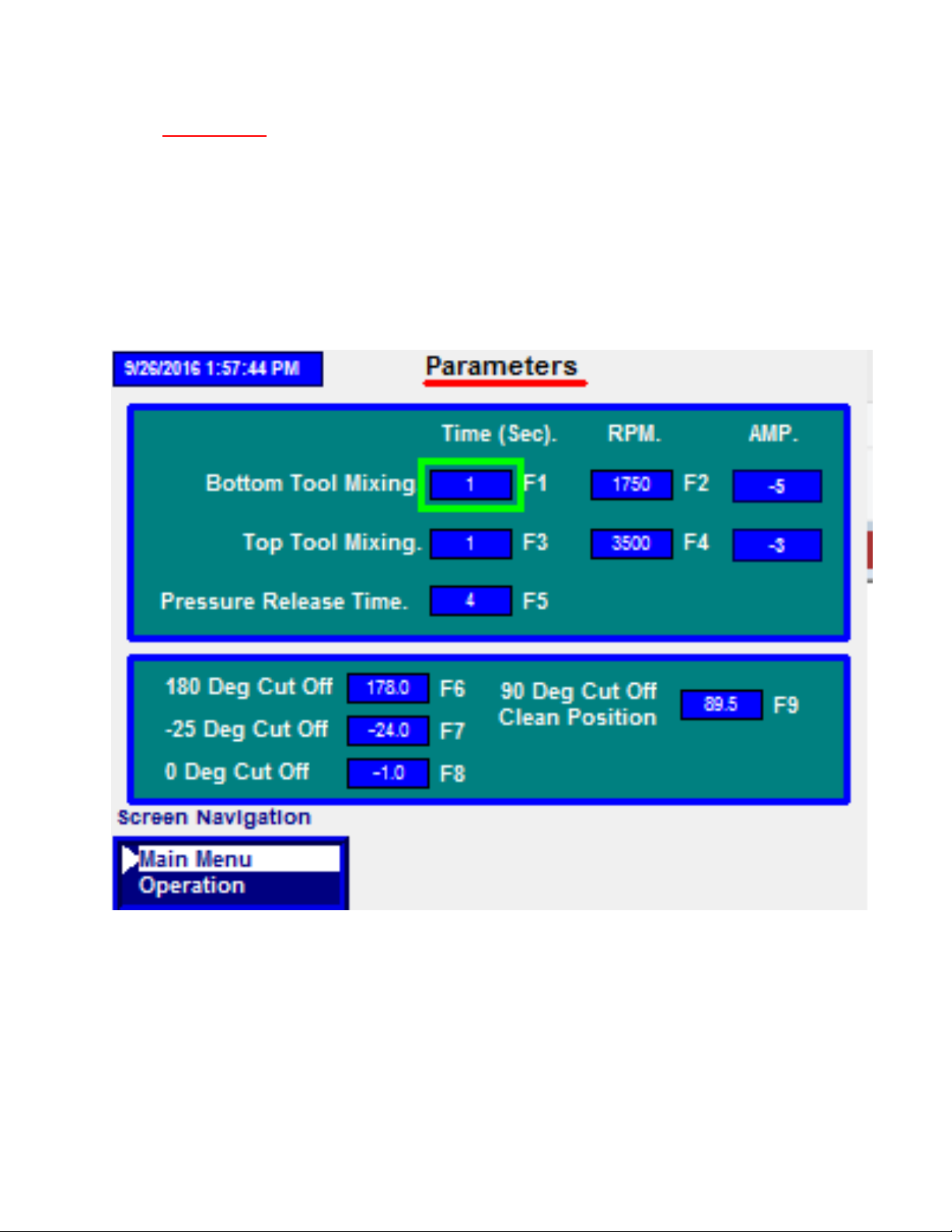

Enter Parameters in the Parameters Screen

Select Reset and AutoStart/Restart (Yellow & Green Button on Control Panel) to reset/abort to

a new batch

Roll Hopper into place

When Hopper is in place, Green Start permissive indication is given and hopper image is shown

on the PLC

"Hopper Up (F1)" indication is given in Yellow Box

Select Hopper Up Push Button on Control Panel or F1 on PLC

Once Hopper is lifted, "Hopper Clamp (F3)" indication is given

Select Hopper Clamp Push Button or F3 on PLC

Once Hopper is clamped, "Hopper Down (F2)" indication is given

Select Hopper Down Push Button or F2 on PLC

Once hopper cylinders are down, "Rotate to 180 Deg (ILPB7)" indication is given

Select Rotate to 180 Deg (ILPB7) Push Button and keep Push Button pressed

Once Hopper is at 180 degrees, "Run Tool (F5 & F7)" indication is given.

To run the top tool, select the Top Tool Push Button and then F5 on the PLC

To run the bottom tool, select the Bottom Tool Push Button and then F7 on the PLC

To run both tools at the same time, select Both Tools Push Button and then F5 & F7 on the PLC

Tool RPM's, Set Times, & Accumulated Times can be seen on the PLC

Once the tools are run, "Rotate to -25 Deg (ILPB6)" indication is given

Select Rotate to -25 (ILPB6) Push Button

Once hopper at -25 degree position, "Jog Tools (F5 & F7)" indication is given

Select F5 & F7 to jog the mixing tools to knock material that has built up during the cycle

"Rotate to 0 Deg (ILPB5)" indication is given

Select to Rotate to 0 Degree (ILPB5) push button

Once hopper is at 0 degree position, "Hopper at 0 Deg" indication is given

"Vent Open" indication is given

Select Vent Open push button to vent pressure and keep pressed down.

"Hopper Up (F1)" indication is given

Select Hopper Up push button or F1 on PLC