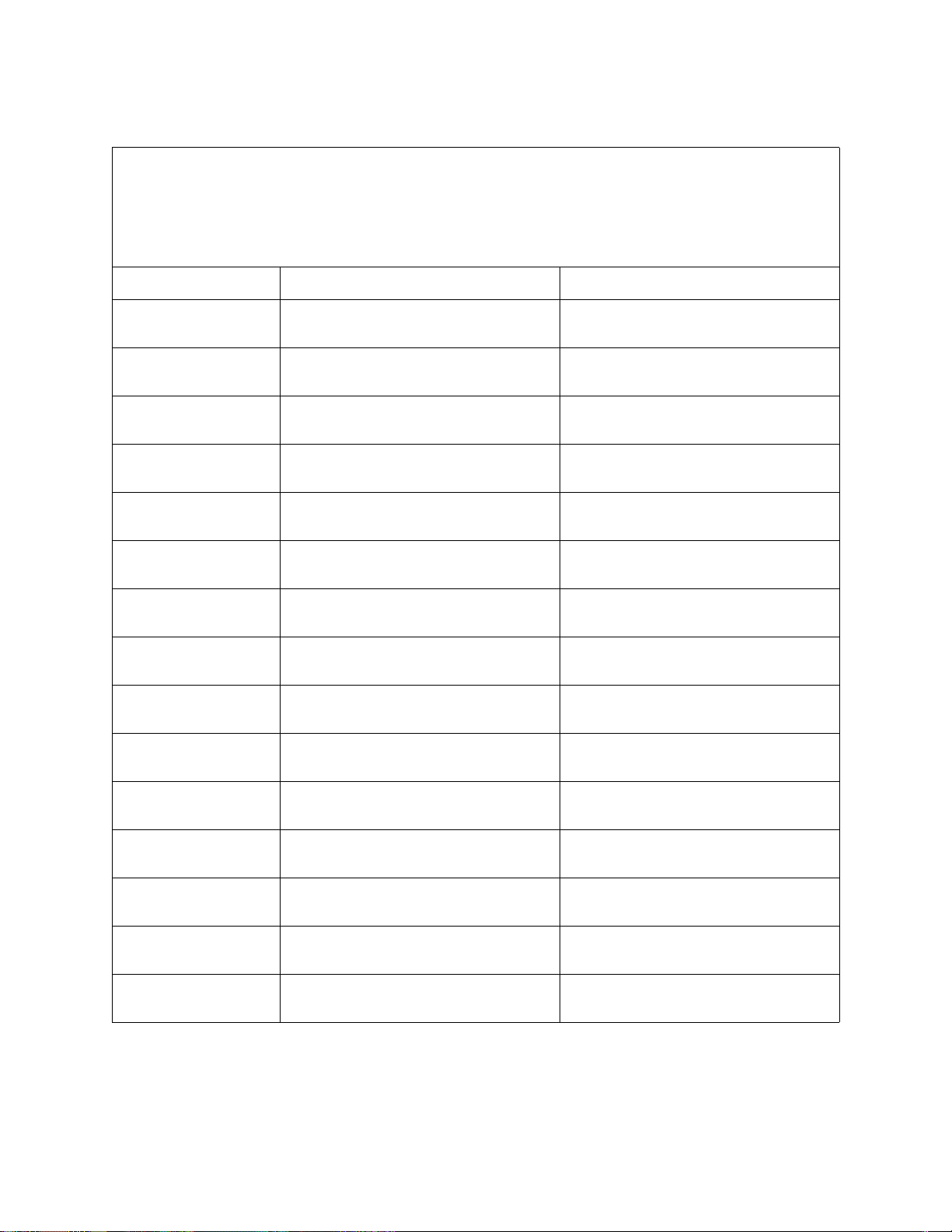

TABLE OF CONTENTS

REM - GRAINVAC VR12

9000-00-0042 R3 3

1. Introduction .......................................................................................................................... 5

1.1. Equipment Purpose.................................................................................................. 6

1.1.1. General Description.................................................................................... 6

1.2. Intended Use............................................................................................................ 6

1.2.1. Misuse........................................................................................................ 6

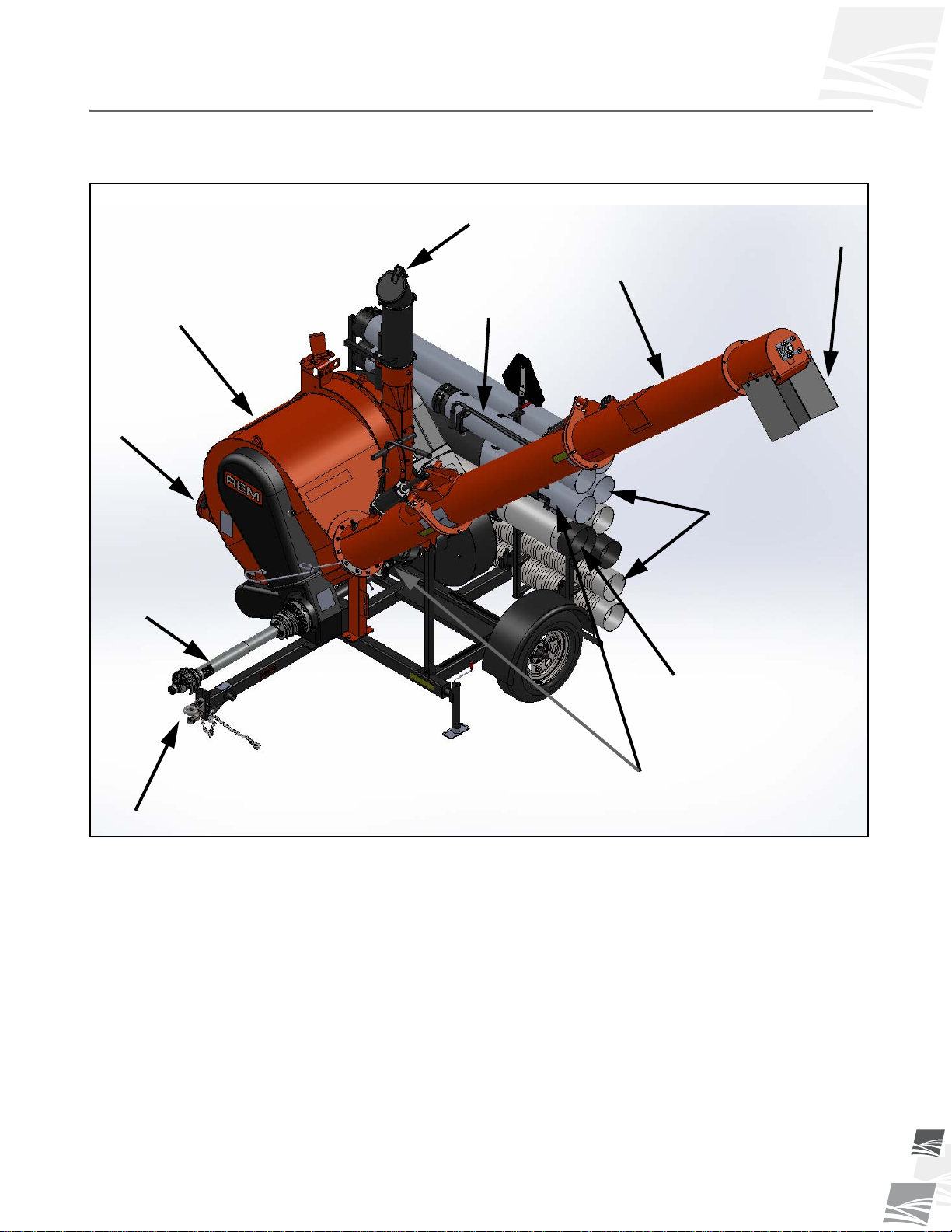

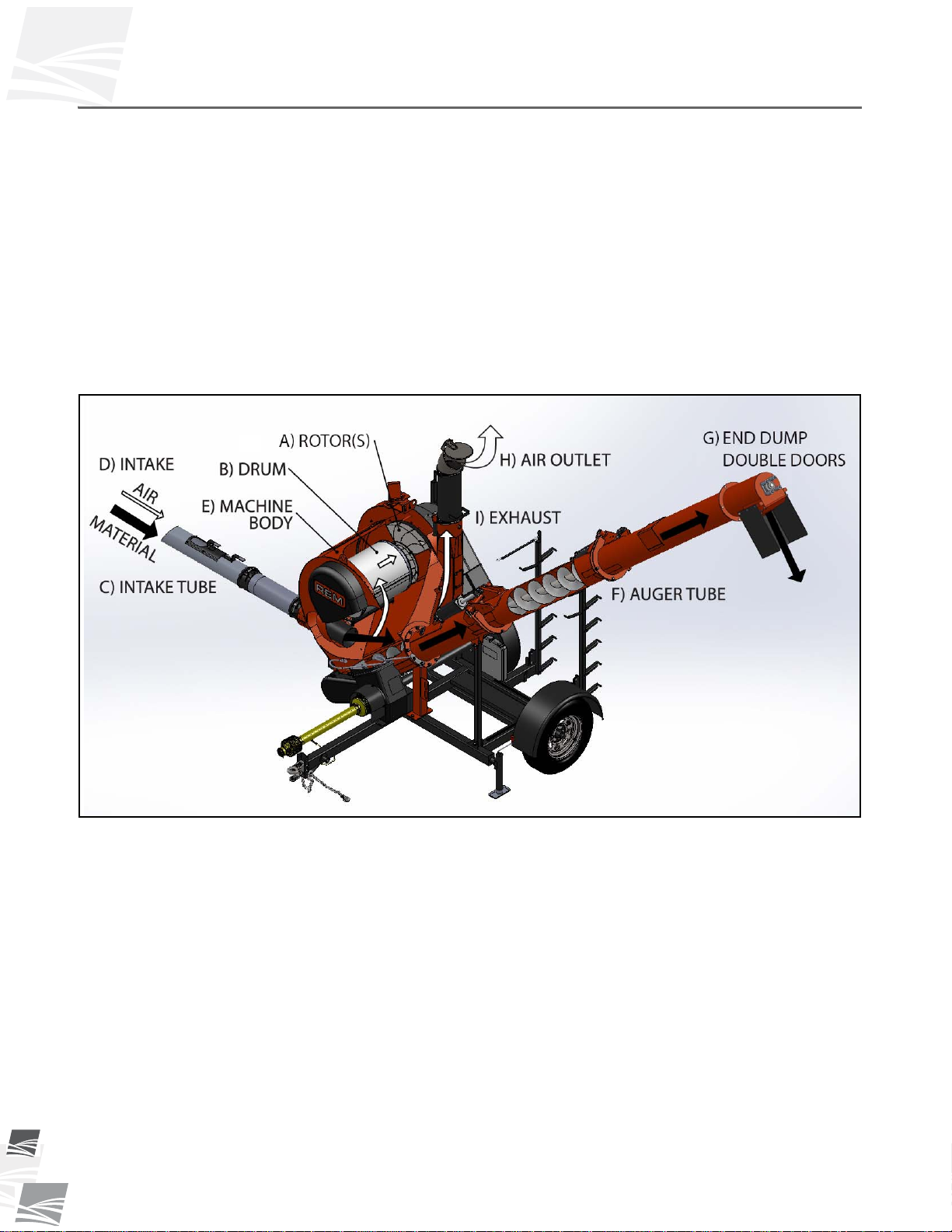

1.3. Components Overview............................................................................................. 7

1.3.1. Functional Overview................................................................................... 8

2. Safety .................................................................................................................................... 9

2.1. Safety Alert Symbol and Signal Words .................................................................... 9

2.2. General Safety ......................................................................................................... 9

2.2.1. Personal Protective Equipment (Required to be Worn)............................ 10

2.2.2. Safety Equipment Required...................................................................... 10

2.3. Work Area Safety................................................................................................... 10

2.4. Overhead Power Lines........................................................................................... 11

2.5. Drives and Lockout Safety ..................................................................................... 12

2.5.1. PTO Driveline Safety................................................................................ 12

2.5.2. Hydraulic Power Safety............................................................................ 12

2.6. Rotating Parts Safety ............................................................................................. 13

2.7. Rotating Flighting Safety........................................................................................ 13

2.8. Tire Safety.............................................................................................................. 13

2.9. Safety Decals......................................................................................................... 14

2.9.1. Decal Installation/Replacement................................................................ 14

2.9.2. Safety Decal Locations and Details.......................................................... 14

3. Transport............................................................................................................................. 27

3.1. Transport Safety..................................................................................................... 27

3.2. Attaching & Transporting GrainVac with Tractor or Truck...................................... 28

4. Operation ............................................................................................................................ 31

4.1. Operating Safety .................................................................................................... 31

4.2. Pre-Operational Checklist ...................................................................................... 31

4.3. GrainVac Lockout................................................................................................... 32

4.4. Machine Break-In................................................................................................... 32

4.5. Tractor Requirements............................................................................................. 33

4.6. Positioning and Set-Up........................................................................................... 33

4.6.1. Jack Stabilizer Set-up............................................................................... 36

4.6.2. Auger Hydraulic Lift.................................................................................. 36

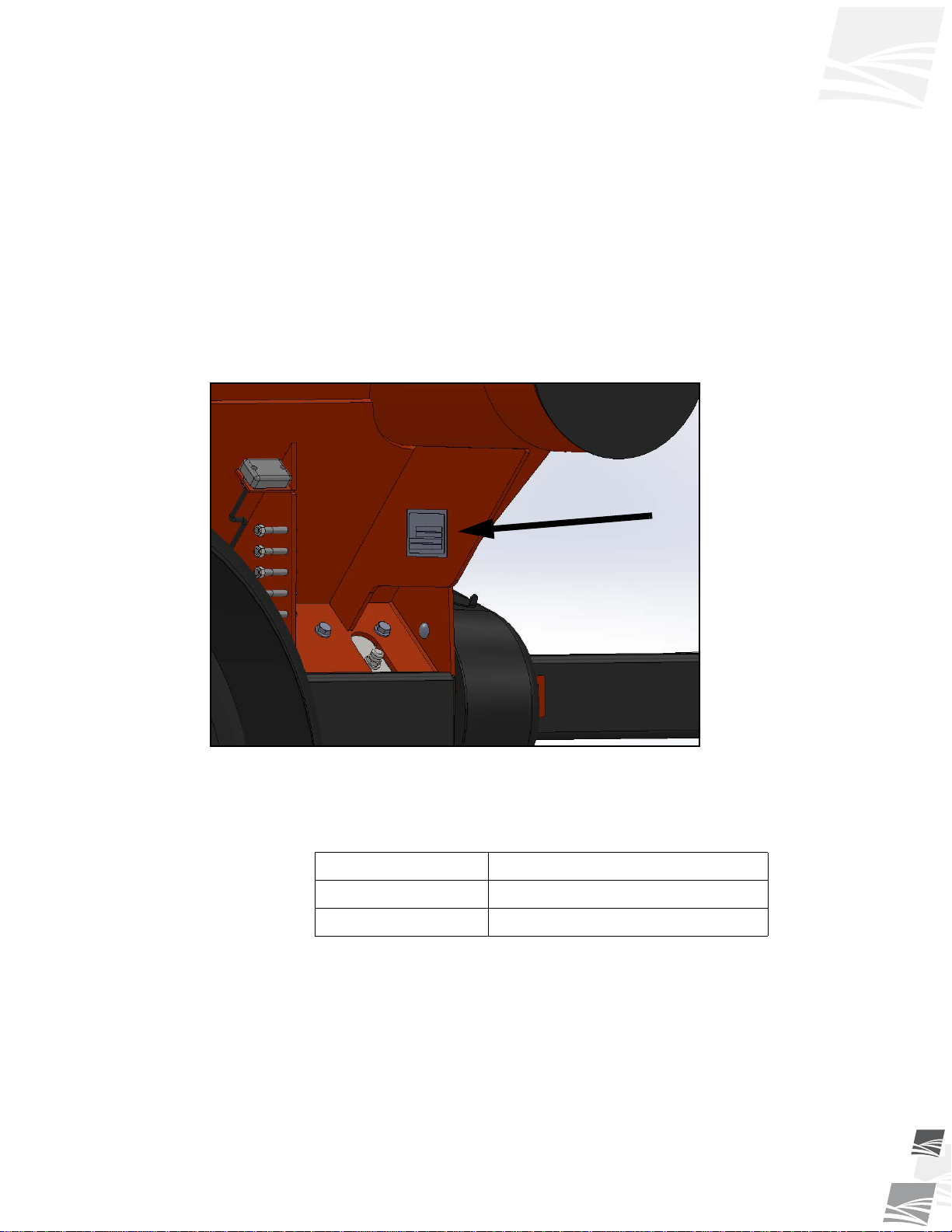

4.7. REM Tachometer / Hour Meter.............................................................................. 38

4.8. Grain Vacuum Operation Procedure...................................................................... 39

4.8.1. Applications & Characteristics of Hoses & Tubes .................................... 45

4.8.2. The “9 S’s of GrainVac Performance” ...................................................... 45

4.9. Shutdown Procedures............................................................................................ 46

4.9.1. Normal Shutdown..................................................................................... 46

4.9.2. Emergency Shutdown .............................................................................. 48