2. Scale installation procedure.

Refer to the relevant RGH22 or RGH41 system installation guides for general details of scale

application including: location, orientation, protection and operating environment. Also scale and

mounting surface (substrate) preparation.

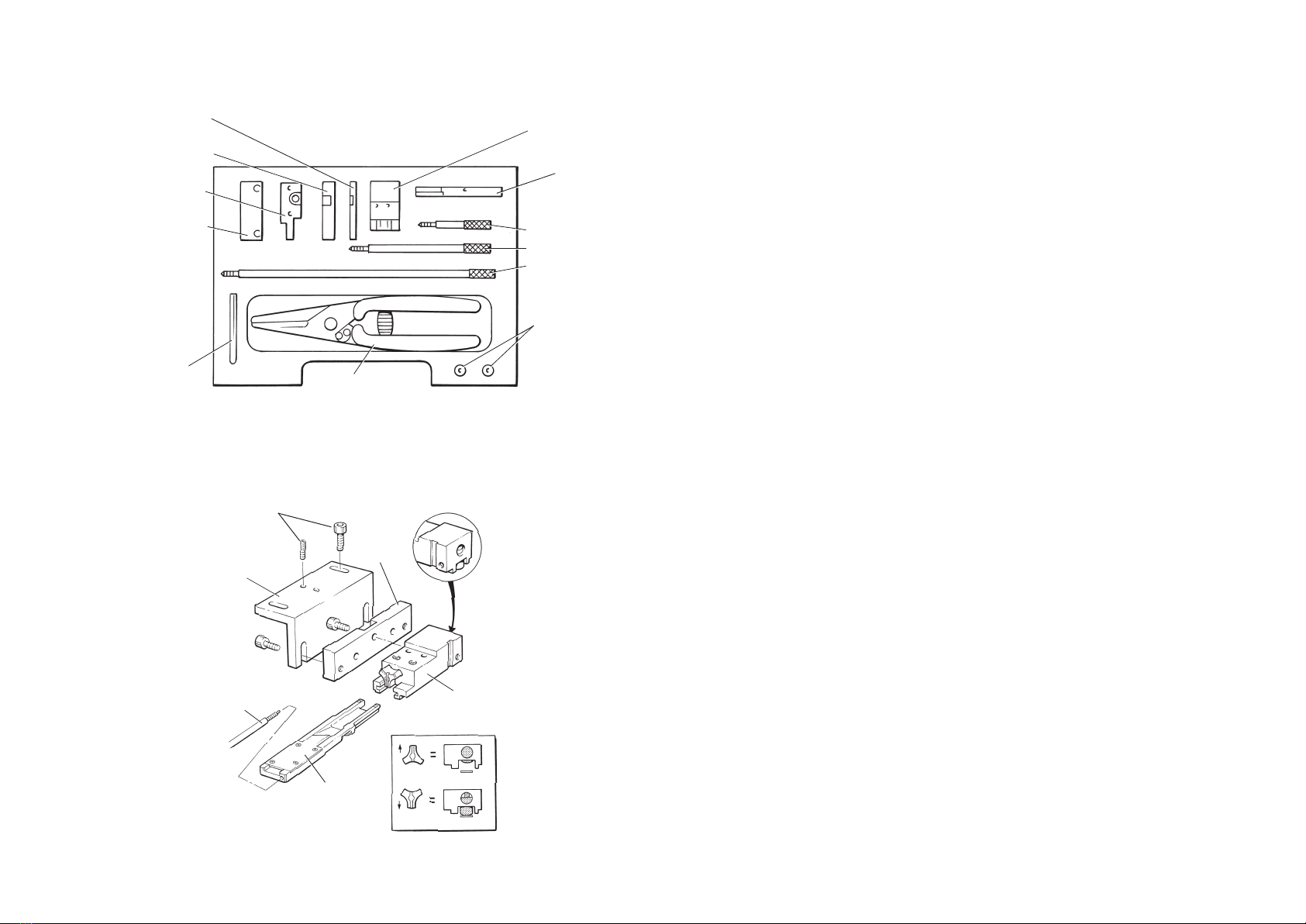

2.1 Applicator assembly.

Select an appropriate adaptor, as described in section 3, and attach it to the applicator body using

the screw and hexagon key provided. This will give either 11.5 mm or 15.5 mm offset dimension

from the scale centreline to the mounting face.

2.2 Axis preparation.

Refer to the relevant RGH22 or RGH41 system installation guides for axis preparation details.

Mark a line on the substrate parallel to the axis guideway at the desired position of the scale centreline.

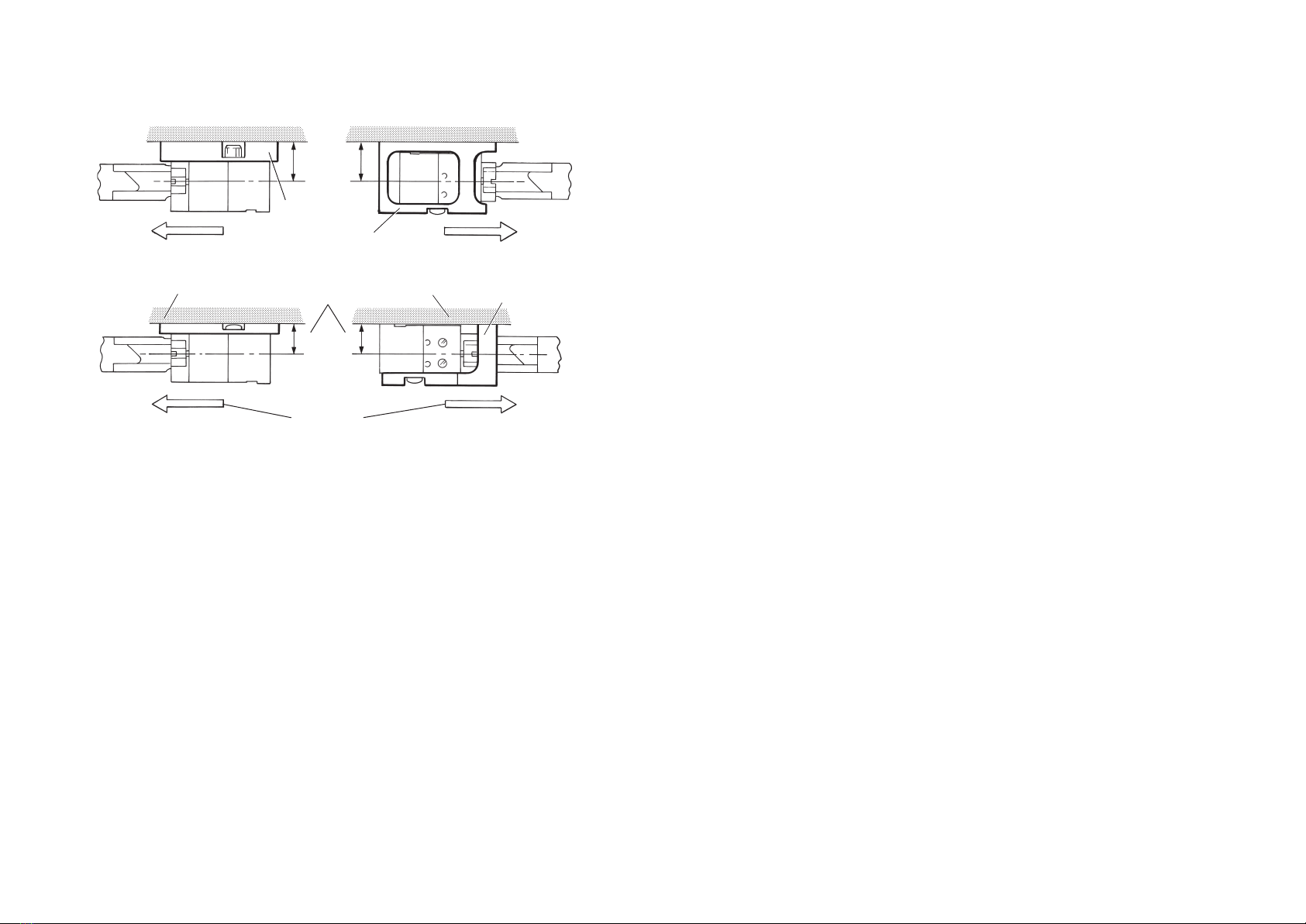

2.3 Readhead mounting bracket alignment.

To lay the scale at a given position using the

RGA22 applicator, it is necessary to set the

machine bracket, on which the readhead mounts,

at the appropriate offset given in 2.1 above,

from the known scale centreline position.

1. Set the machine bracket with 11.5 mm or

15.5 mm offset from scale centreline,

as appropriate, depending upon which

way round the readhead is to be mounted.

This can be done by measurement or

by attaching the assembled applicator to

the machine bracket, locating it into the

readhead setting gauge and adjusting

the position to align the setting gauge

notch over the marked centreline,

see Figure 2a.

2. Adjust the readhead mounting bracket

to ensure that the readhead mounting

face is square to the scale’s mounting

surface and parallel to the axis guideway

within the tolerances shown in Figure 2a.

2.4 Scale guide preparation

1. Cut scale to the required length and feed into

the scale guide slot. The scale prole is

symmetrical, therefore it can be applied

either way round.

Hint: To ensure that the scale backing paper

engages in the splitter blade, carefully roll

back the leading 5-10 mm and then

re-attach. Do not fold the backing paper

as this will prevent correct engagement

2. Feed the scale as far as point X,(Figure 2b),

checking that the backing paper is removed

correctly by the feeding action.

3. If required, lock scale at this position

by tting and lightly tightening the

extension handle as shown.

Do not use excessive torque as this

could damage the scale guide or scale face.

2.5 Scale application

1. Move the axis to the start of travel, noting direction of scale application.

2. Turn plunger release knob to the UP position to ensure that applicator plunger is retracted.

3. Engage the scale guide into the applicator head

until the detent clicks

(see Figure 2c).

Figure 2b Scale insertion

Scale Release

paper

Scale guide

‘Lock’ Extension handle

X

Figure 2c Scale positioning

20

Start of

measuring length

Limit stop

Limit of

travel

Plunger release knob

‘UP’-retracted

Extension

handle

‘unlock’ End of

scale mark

Scale

centre-line

mark

Notch aligns with

scale centre-line

Readhead

setting gauge

Figure 2a Applicator set-up

*0.5 - 1.0

F-Axis guideway

15.5- Adaptor M - 9531-0193

11.5-Adaptor M-9531-0191

0.1 F

0.15

*

Adaptor

Machine bracket

3