7

RGH25F RGS20 installation guide

For reliable operation, the SET UP LED should be at least Green,

ideally blue or purple when readhead is moved along the full axis travel.

Readhead mounting and alignment

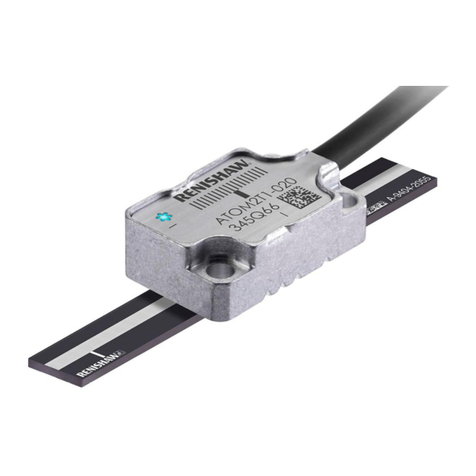

System description

The RGH25F encoder system consists of a common readhead in standard or UHV compatible form, coupled to

the interface, which gives accurate, industry standard outputs. There are 10 versions of the REF interface, offering

digital resolutions of 5 μm to 5 nm, and an analogue version giving 1 Vpp output. The digital REF interfaces are

available with a variety of different clocked outputs, each interface option having a different maximum speed and

minimum customer counter clock frequency, ranging from 1 to 50 MHz.

Mounting brackets

The bracket must have a at mounting surface, enable conformance to the installation tolerances, allow adjustment

to the rideheight of the readhead, and be sufciently stiff to prevent deection or vibration of the readhead

during operation. For easier installation, adjust the roll and yaw of the bracket with respect to the axis of readhead

travel before the RGH25F is attached. This can be done with a clock gauge and a precision square.

Readhead set-up

To set nominal rideheight, position readhead spacer with ‘L’shaped aperture under the optical centre of the

readhead to allow normal LED function during set-up procedure. Ensure that the scale, readhead optical window

and mounting face are clean and free from obstructions.

NOTE: Ensure readhead xing screws are tightened to 0.5 Nm-0.7 Nm.

Green Orange Red

Blue

Purple

Ya w

0° ± 0.5°

Pitch

0° ± 1°

Roll

0° ± 1°

0.8 ± 0.1 mm

Rideheight

SET UP LED colour, except

at reference mark position.

REF interface features

Self-tuning active correction

The REF interface actively corrects for input signal imperfections to optimise system accuracy.

Corrections are made for the following:

Automatic Offset Control (AOC) – adjusts offset independently for the sine and cosine signals

Automatic Gain Control (AGC) – ensures consistent 1 Vpp signal amplitude

Automatic Balance Control (ABC) – adjusts the gain to equalise the sine and cosine signals

These correction mechanisms operate over the full working speed range of the readhead. The user can

disable/enable the AGC by depressing the CALIBRATE button for greater than 3 seconds.

REF Interface LED diagnostics

The REF interface SETUP LED provides visual feedback of signal strength, error condition and reference

mark phasing, for setup and diagnostic use.

LED Indication Status Alarm

output*

SET-UP Incremental Flashing purple High signal alarm condition;

Signal level >135% Ye s

Purple Normal set-up;

Signal level 110% to 135% No

Blue Optimum set-up;

Signal level 90% to 110% No

Green Normal set-up;

Signal level 70% to 90% No

Orange Low signal;

Signal level >50% and <70% No

Red Low signal;

Signal level >20% and <50% No

Flashing Red

Low signal alarm condition;

Signal level <20%;

System in error

Ye s

Flashing Blue Over speed; system in error Ye s

Reference mark

(when traversing

the reference mark

<100 mm/s only)

Red ash Well phased reference mark No

Orange ash Poorly phased reference mark No

Blank ash Reference mark not phased No

CAL/AGC Operating Yellow AGC is active No

Blank AGC inactive No

Calibration Slow Yellow

ashing Calibration routine underway No

Fast Yellow

ashing Calibration failure No

*Alarm output will take the form of 3-state or line driven differential E signal depending on interface conguration.

Also some congurations do not output overspeed alarm. See Interface part numbers in the RGH25F encoder system

data sheet for details.

System calibration