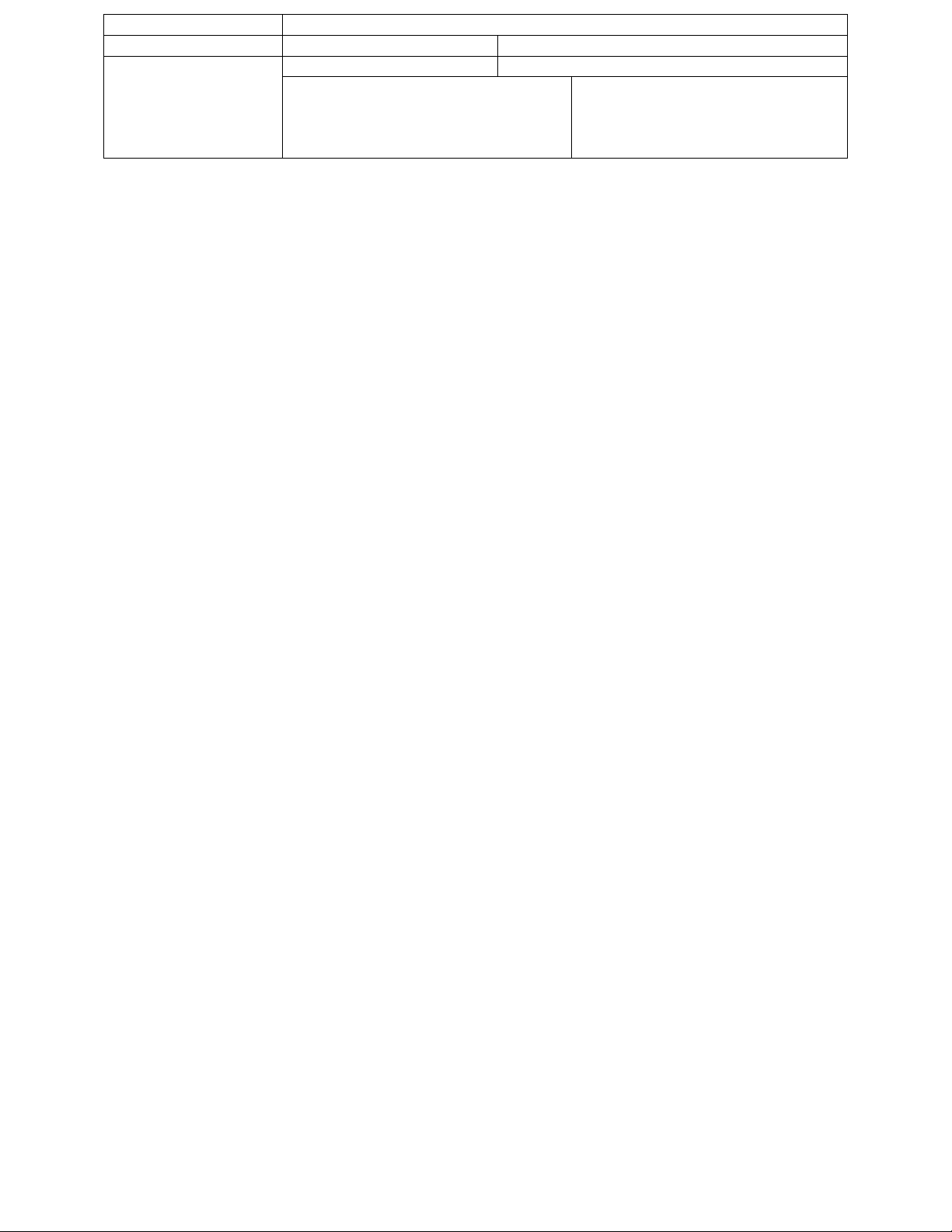

Soft-Cut Gas Saw Model GX-1500

Material Needed

Open Area to demonstrate

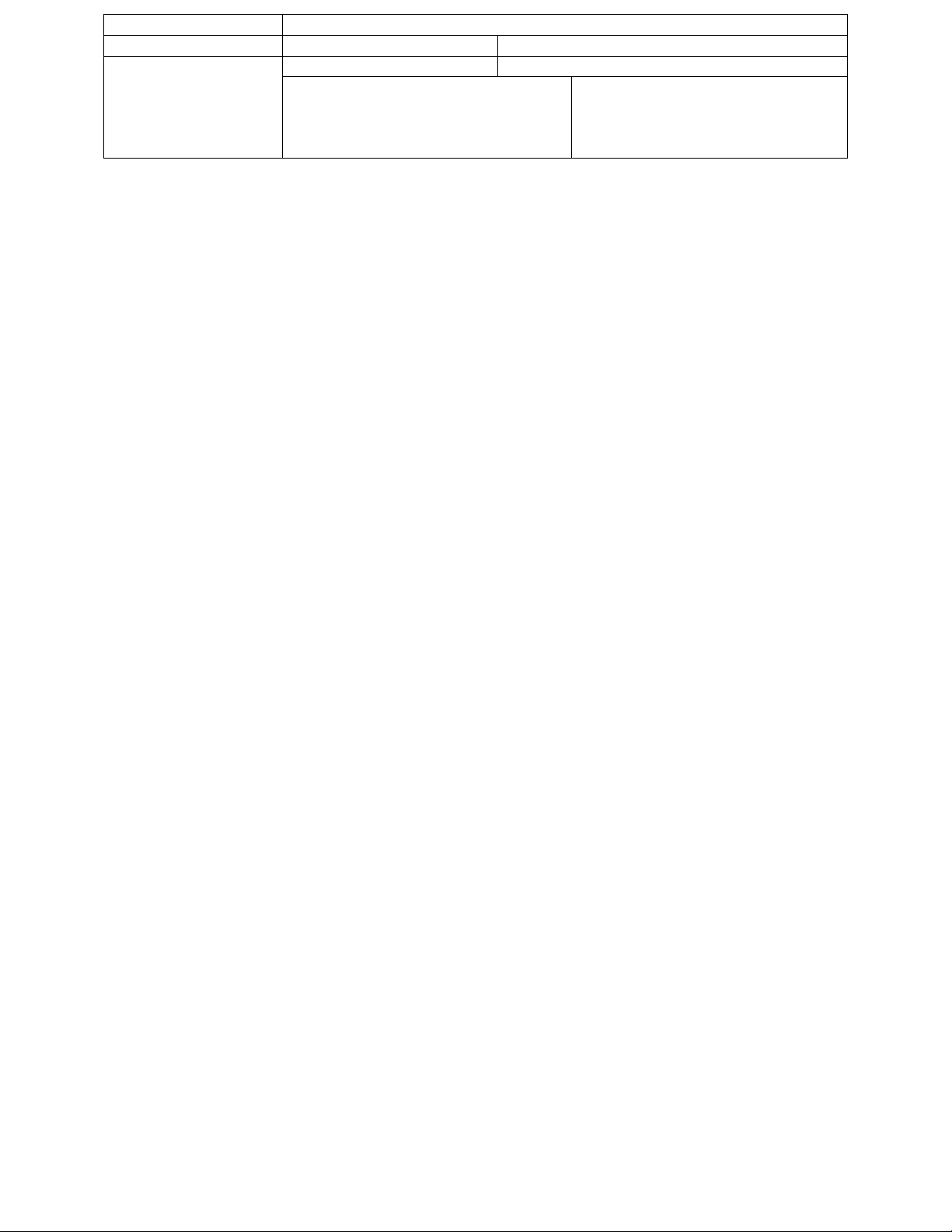

starting & shutdown procedures

Hard Hat-Safety Glasses-Face

Shield-Work Gloves-Steel Toe

/Composite Boots & Hearing

PLATE IS USED, THE EDGES WILL RAISE ON THE SAW CUT AND MAJOR

SPALLING WILL OCCUR WHEN TRAVELED UPON).

12. INSTALL BLADE COVER. (CLEAN INSIDE OF BLADE COVER THOROUGHLY)

13. LIFT FRONT OF SKID PLATE TO ENSURE THE BLADE SLIDES THROUGH THE

SKID PLATE FREELY. (DO NOT CHECK WHILE SAW IS RUNNING)

THE SKID PLATE IS THE MOST IMPORTANT PART OF THE SOFT-CUT SAW. IF

IT IS BENT, BOWED OR DAMAGED, SPALLING OR RAVELING OF A CUT MAY

RESULT, SO STORE PLATES CAREFULLY AND INSTALL THEM PROPERLY

GENERAL SAFETY RULES

1. AVOID DANGEROUS ENVIRONMENT. DO NOT USE SAW IN DAMP OR WET

LOCATIONS. KEEP WORK AREA WELL LIT. DO NOT EXPOSE SAW TO RAIN. DO

NOT USE SAW IN PRESENCE OF FLAMMABLE LIQUIDS OR GASES.

2. DRESS PROPERLY. DO NOT WEAR LOOSE CLOTHING OR JEWELRY WHICH

CAN BE CAUGHT IN MOVING PARTS.

3. PROPER PERSONEL PROTECTIVE EQUIPMENT REQUIRED FOR THE USE OF

THIS SAW IS A HARD HAT, SAFETY GLASSES, FULL FACE SHIELD AND

HEARING PROTECTION. IF THE CUTTING OPERATION IS DUSTY, A DUST MASK

MAY BE REQUIRED.

4. STAY ALERT. WATCH WHAT YOU ARE DOING. USE COMMON SENSE.

5. BARRICADE WORK AREA TO WARN OTHERS OF THE WORK BEING DONE.

6. DO NOT OVERREACH, KEEP PROPER FOOTING AND BALANCE AT ALL TIMES.

7. CHECK SAW THOROUGHLY PRIOR TO USE, CHECK SAFETY GUARDS, CHECK

FOR ALIGNMENT OF MOVING PARTS, BINDING OF MOVING PARTS, BREAKAGE

OF PARTS, MOUNTING AND ANY OTHER CONDITIONS THAT MAY AFFECT ITS

SAFE OPERATION.

8. DO NOT FORCE SAW. IT WILL PERFORM MORE EFFICIENTLY AND SAFER AT

THE RATE FOR WHICH IT WAS DESIGNED.

9. AVOID ACCIDENTAL STARTING. REMOVE KEY FROM SWITCH WHEN

CHANGING BLADES.

10. CAUTION: DO NOT USE DAMAGED BLADES

DANGER: KEEP HANDS AWAY FROM CUTTING AREA AND BLADES

BLADE GUARD: KEEP BLADE GUARD IN PLACE

STORAGE:

WHEN NOT IN USE, THE KEY SHOULD BE IN THE OFF POSITION. THE GAS

VALVE SHOULD BE IN THE OFF POSITION. THE BLADE SHOULD BE REMOVED

AND THE MACHINE LOWERED SOTHE BLADE GUIDE IS ON THE FLOOR TO