!

!

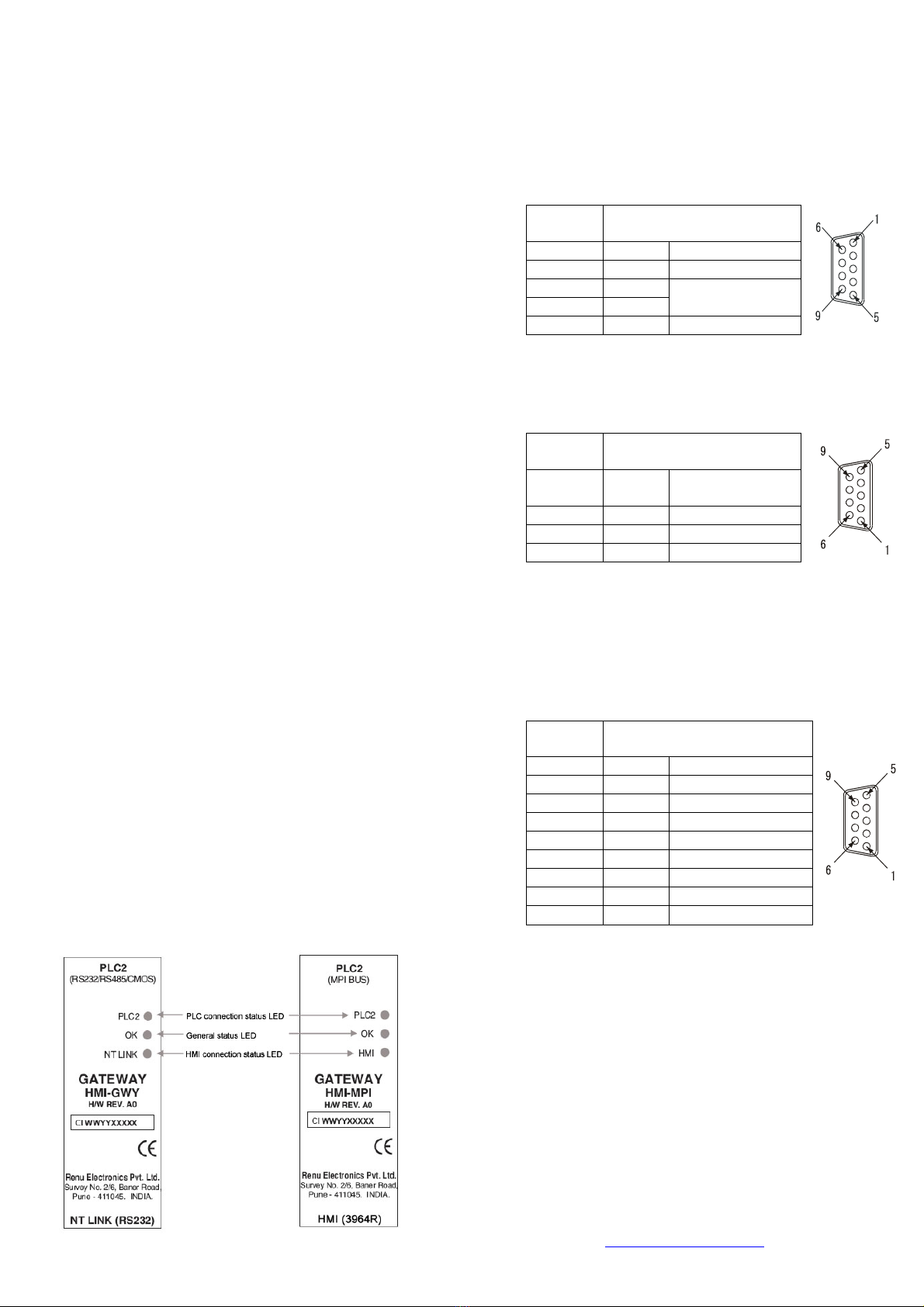

Model

GWY- MPI

GWY- HMI

PROTOCOL CONVERTER

INSTRUCTION SHEET

This sheet has important information on how the Unit is used.

Please read through this manual thoroughly before using the

Unit. And after reading this manual, please keep this manual

in a place where others can easily access for future

reference.

Renu Electronics Pvt. Ltd.

© 2006. All rights reserved

Safety Precautions

■Definition of Precautionary Information

WARNING Not following a precaution given as

a “Warning” may result in fatal or

serious injury.

■Warnings

WARNING Do not attempt to take the Unit apart

and do not touch any internal parts

while power is being supplied. Doing

either of these may result in electric

shock.

Precautions

1. When unpacking the Units, check carefully for any

external scratches or other damage. Also, shake the Units

gently and check for any abnormal sound.

2. Always tighten the connector screws after connecting

communication cables.

3. Double-check all the wiring before turning on the power

supply.

4. Confirm that the system will respond safely before turning

the power supply on or off.

5. Do not attempt to disassemble, repair, or modify the Units

in any way.

6. Dispose of the Units, according to local ordinances as

they apply.

Operating Precautions

You must allow sufficient leeway in ratings and performance

and provide proper fail-safe and other safety measures

when using the Unit in any of the following applications. Be

sure also to consult your PNSPO representative before

actually attempting any of these applications.

1. Applications under conditions or environments not

specified in user manuals.

2. Applications for nuclear reactor control, train facilities,

aviation facilities, motorised vehicles, furnaces, medical

equipment, amusement equipment and safety

equipment.

3. Applications strongly related to human life or property,

particularly those requiring safety.

Operating conditions

Operating temperature: 0°C to 60°C

Storage temperature: -20°C to 80°C

Humidity: 10% to 90%RH, Non-condensing

Weight : approx. 125 gramms

External Dimensions

The size of the Protocol converters is

105mm (length) * 51mm (width) * 40mm (height).

Correct Use

1. Do not install the Unit in any of the following locations.

•Locations subject to rapid changes in temperature.

•Locations subject to temperatures or humidities outside

the range specified in the specifications.

•Locations subject to condensation as the result of high

humidity.

•Locations object to splashing chemicals or solvents.

•Locations subject to corrosive or flammable gasses.

•Locations subject to strong shock or vibration.

•Locations outdoors subject to direct wind and rain.

•Locations subject to strong ultra-violet light.

2. Take appropriate and sufficient countermeasures when

installing systems in the following locations.

•Locations subject to static electricity or other forms of

noise.

•Locations subject to strong electromagnetic or

magnetic fields.

•Locations close to power supply lines.

•Locations subject to possible exposure to radioactivity.

3. Do not use benzene, paint thinner or other volatile solvents,

and do not use chemically treated cloths.