AT120A-E; AT140A-E; AT150A,B,D-F; AT160B; AT175A-D,F TRANSFORMERS

68-0054—06 2

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

a sample unit may not match the listed specifica-

tions exactly. Also, this product is built and tested

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

Models: AT120A-E; AT140A-E; AT150A,B,D-F; AT160B;

AT175A-D,F.

Electrical Ratings: See Table 1.

aRefer to regulation curves.

bVoltage is 27.0V on AT150F and AT175F models.

Wiring Connections:

“A”, “C”, and “D” models: Primary—9 inch (230 mm) leadwires;

Secondary—screw terminals.

“B” and “E” models: Primary—9 inch (230 mm) leadwires or

fixed 1/4 inch (6 mm) quick-connects. Different length

leadwires and leadwires with stripped ends or with termi-

nals attached also available. Specify when ordering.

Secondary—9 inch (230 mm) leadwires or fixed 1/4 inch (6

mm) quick-connects. Different length leadwires, leadwires

with stripped ends or with terminals attached, and screw

terminals also available. Specify when ordering.

“F” models: Primary and Secondary—9 inch (230 mm) lead-

wires.

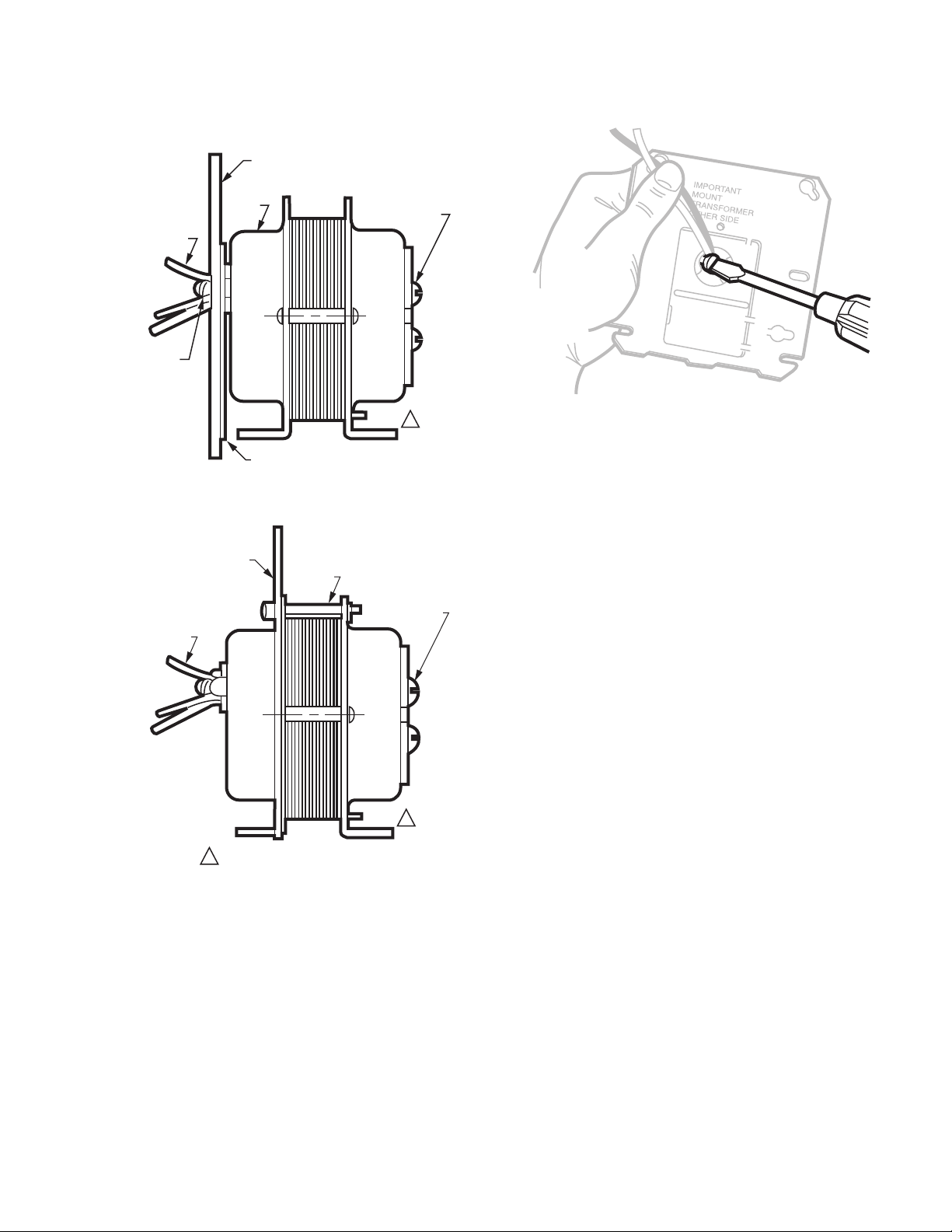

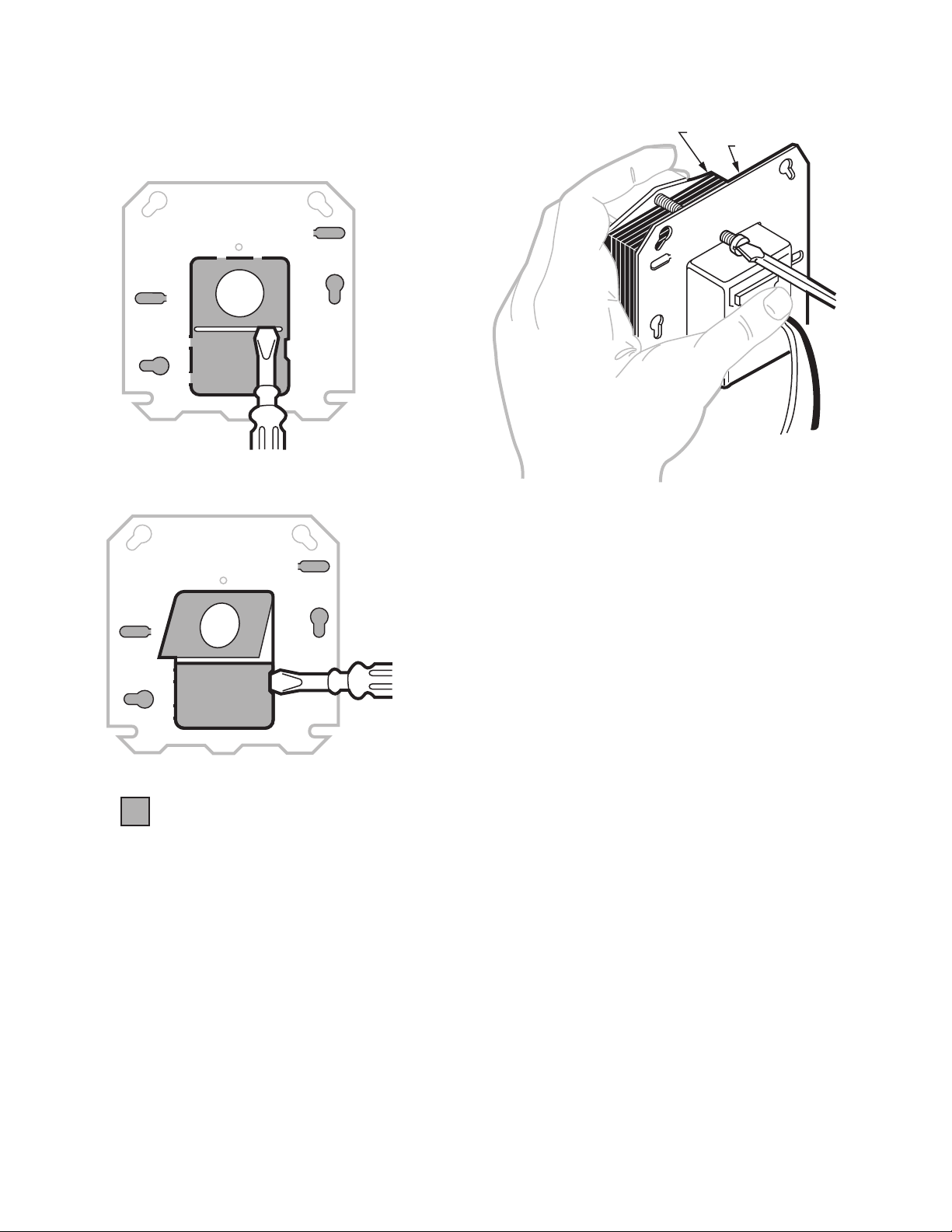

Mounting Means:

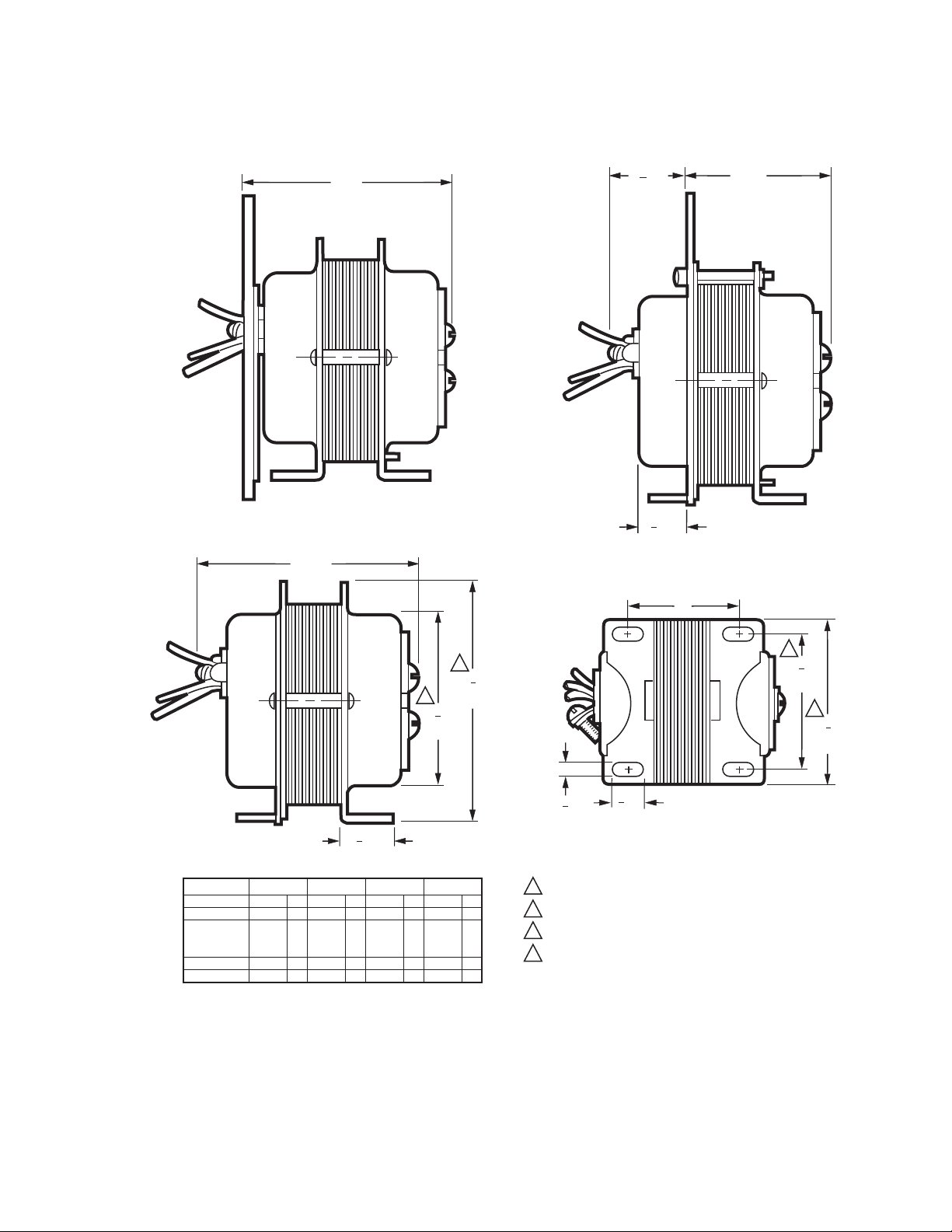

Dimensions: See Fig. 1 through 5.

Regulation:

See transformer regulation curves, Fig. 6 through 10.

Overcurrent Protection:

Inherent on AT120, AT140, and AT150. Thermal fusible link on

AT160 and AT175. Circuit breaker on AT150F and AT175F

models.

Approvals:

UNDERWRITERS LABORATORIES INC. LISTED (“A”, “C” and “F”

models): File No. E14881, Guide No. XOKV.

UNDERWRITERS LABORATORIES INC. COMPONENT RECOG-

NIZED (“B,” “D,” “E” models): File No. E14881, Guide No.

XOKV2.

All models conform to Underwriters Laboratories Inc. Stan-

dard UL 1585.

NATIONAL ELECTRICAL CODE: Class 2 not wet, Class 3 wet.

Optional Specifications:

End bells or caps on “B” through “E” models.

Terminations on “B” through “E” models.

Circuit breaker reset button on “F” models.

National Electrical Code:

Class 2 not wet, Class 3 wet

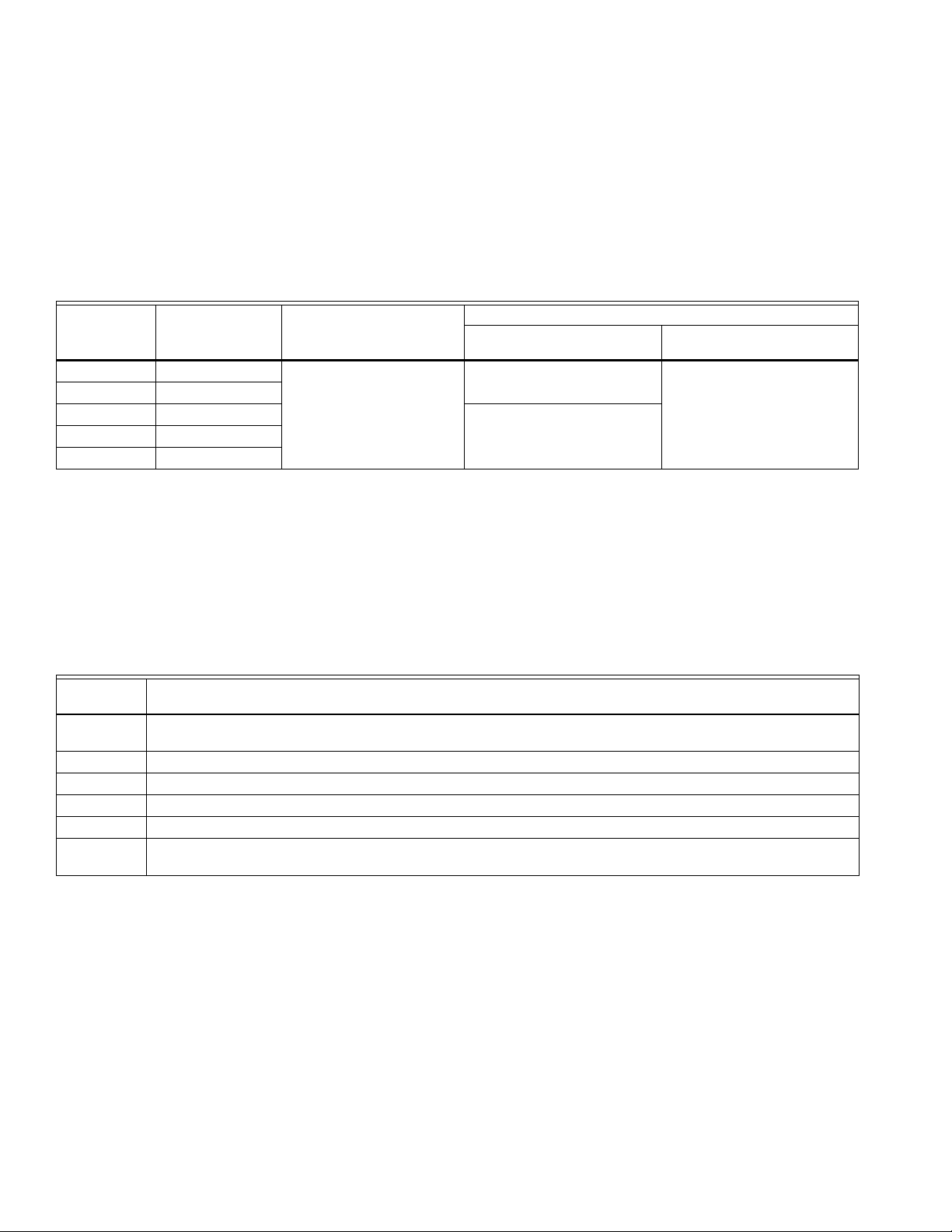

Table 1. Electrical Ratings.

Model

Number

Output Rating at

100 Percent Power

FactoraPrimary Input Voltage

(60 Hz)

Secondary Output Voltage

Open Circuit At Rated Power Output

AT120 20 VA 120, 240, 277, 480, 120/240,

208/240, 240/277, 277/480,

120/208/240, 208/240/480,

or 208/277/480V

27.0 24.0

AT140 40 VA

AT150 50 VA 27.5b

AT160 60 VA

AT175 75 VA

Model Suffix

Letter Mounting Means

A Includes clamp for outlet box knockout, 4 x 4 inch mounting plate for 2 x 4 inch or 4 x 4 inch outlet box, and

mounting feet for surface mount.

B Foot-mounted.

C Includes clamp for outlet box knockout.

D Integral 4 x 4 inch mounting plate fits 2 x 4 inch or 4 x 4 inch outlet box.

E Panel mounted with two No. 8 screws (not included).

F Includes 1/2-14 NPSM conduit connector and lock nut for mounting on plate or panel (not included) with 7/8 in.

knockout, and mounting feet for surface mount.