en

5

Before flushing the system

ÎDisconnect the expansion vessel from the solar

thermal system.

ÎConnect the pressure hose of the filling and flush-

ing station to the fill valve (5) of the pump station.

ÎConnect the flushing hose of the filling and flush-

ing station to the drain valve (3) of the pump sta-

tion.

ÎClose the ball valve of the pump station (4).

ÎOpen the fill valve (5) and the drain valve (3).

ÎSwitch on the filling pump of the filling and flush-

ing station.

ÎFlush the solar thermal system for at least 15

minutes by means of the filling and flushing sta-

tion until the discharged solar fluid is free of gas

bubbles and dirt particles.

ÎDuring flushing, bleed the solar thermal system

several times until the discharged solar fluid (e. g.

Tyfocor®, see chap. 11) is free of air bubbles.

ÎOpen the ball valve of the pump station (4).

After flushing the system

ÎConnect the expansion vessel to the solar ther-

mal system.

ÎClose the drain valve (3) of the pump station

while the filling pump is running.

BAR

ÎIncrease system pressure (approx. 3.5 - 4 bar).The

system pressure can be read from the pressure

gauge.

ÎClose the fill valve (5).

ÎSwitch off the filling pump.

ÎCheck the pressure gauge to see whether the

system pressure reduces and eliminate leaks

where necessary.

ÎSlowly discharge the heat transfer fluid by means

of the drain valve (3) until the operating pressure

is set.

ÎRemove the hoses of the filling and flushing sta-

tion and screw the caps onto the fill and drain

valves. Manually start the solar thermal pump at

maximum speed (see controller manual) and let

the fluid circulate for at least 15 minutes.

ÎBleed the solar thermal system several times.

ÎCheck the system pressure at the pressure gauge.

%

ÎCheck the antifreeze ratio (not required if a

ready-mix is used).

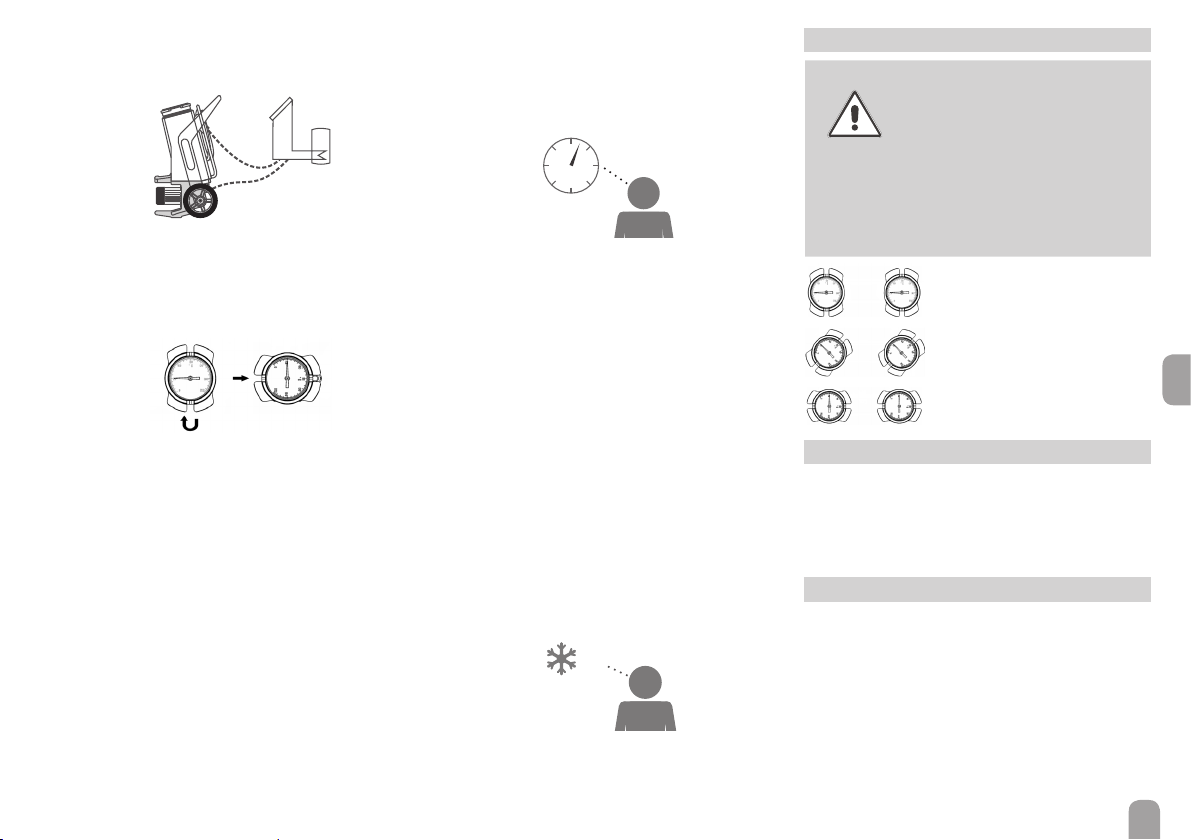

4 Ball valve positions

WARNING! Scald danger! Damage by

overpressure!

When the ball valve is closed, too

high pressure may occur in the

blocked-off line if it is heated.

ÎIn order to prevent scald

danger and damage by

overpressure, make sure

the blocked-off line is not

heated.

Non-return valve in operating

position, fluid flow in flow direc-

tion only.

Ball valve open, fluid flow in both

directions possible.

Ball valve closed, no fluid flow.

5 Draining the system

ÎOpen the ball valve (4).

ÎOpen the air vent at the highest point of the sys-

tem (above the collectors).

ÎOpen the drain valve.

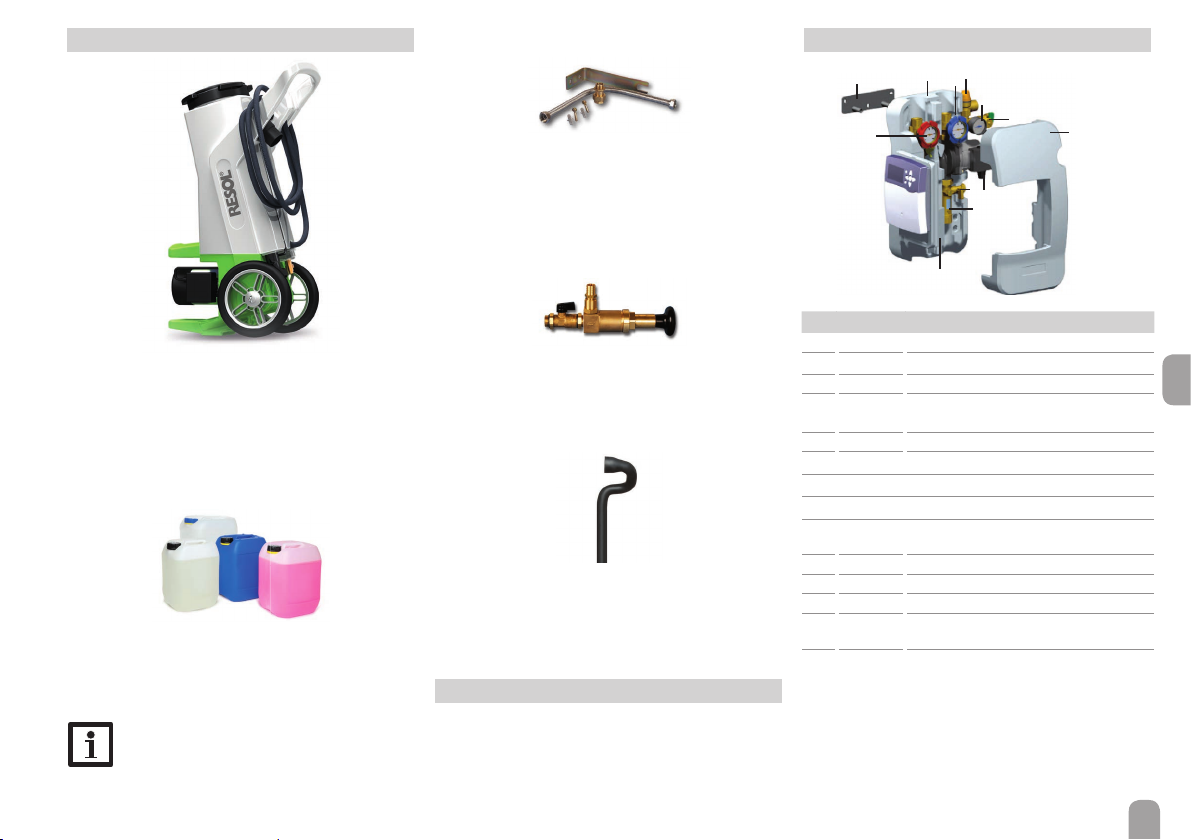

6 Non-return valves

The non-return valves of the pump station are inte-

grated into the ball valves in flow and return and have

an opening pressure of 20 mbar.

In order to completely drain the system, the non-

return valves have to be opened.

ÎFor this purpose, turn the handles of the ball

valves by 45°.

ÎFor normal system operation,open the ball valves

completely.