Page 2 of 10

©Retrotec Inc. 2014

1. Overview......................................................................................................3

2. What’s included ...........................................................................................4

3. Operation.....................................................................................................5

3.1 Connect Adapter between gauge and TEC fan speed controller ................................................ 5

3.2 Set the fan and range being used on the gauge.......................................................................... 5

3.3 Connect Pressure Tubing for Minneapolis Model 3™ ................................................................. 6

3.4 Connect Pressure Tubing for Minneapolis Model 4™ ................................................................. 6

3.5 Connect Pressure Tubing for Minneapolis Duct Blaster®............................................................ 8

4. Adapter Technical Details...........................................................................10

4.1 Fan Compatibility....................................................................................................................... 10

4.2 Gauge Compatibility .................................................................................................................. 10

4.3 LED Power Status Indicator .......................................................................................................10

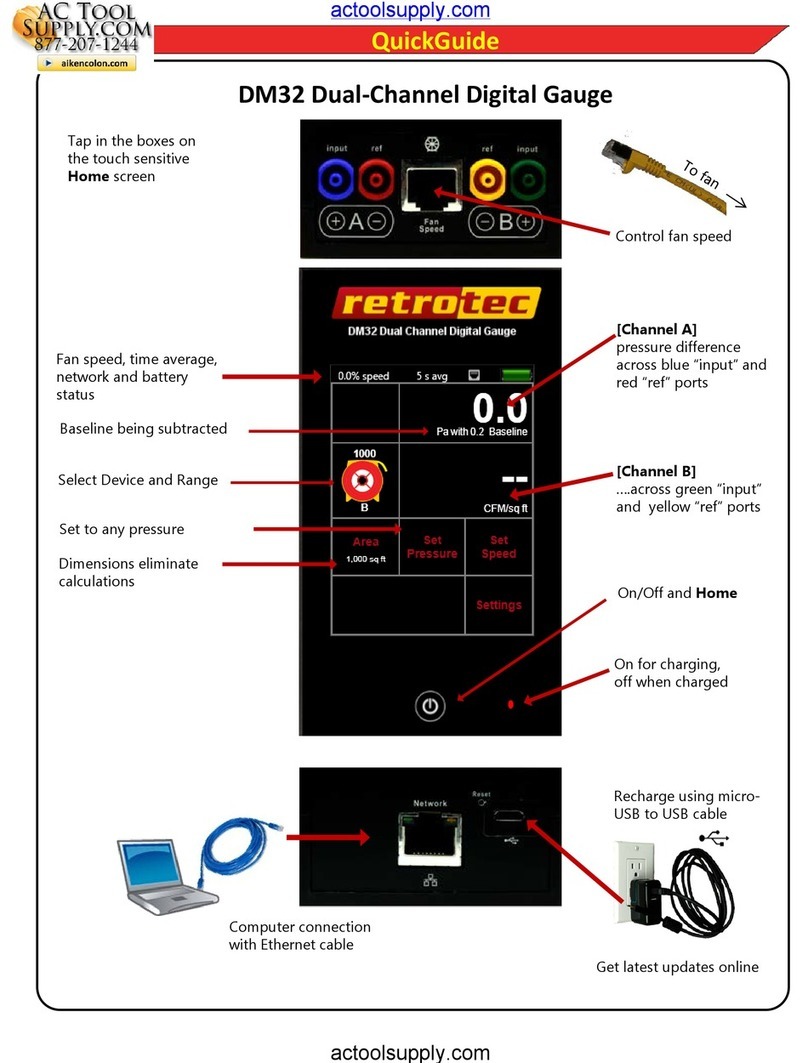

Extra Features the DM32 gives your TEC Devices

Pressurization testing no longer requires the use of an additional tube that is run to the other side of the

cloth. DM32 takes care of this in software and always makes the correct decision.

The True Flow Grid can be corrected in the gauge without using correction tables.

Hole Flow enables you to measure the flow rate from any supply or into any exhaust device just using a

box with a hole cut in it.

Hold readings and convert to any units used worldwide without a calculator.

Blower door can be used to measure air handler flow automatically. Since our Set Pressure can be any

value, simply measure the supply pressure. Set the pressure in the gauge to this pressure, and the

blower door willl measure the air handler flow.