Table of Contents

1Notes on the Manual ............................................................................................................................. 6

1.1 Explanations of the Safety Instructions ............................................................................................. 7

1.2 General Safety Instructions ............................................................................................................... 8

1.3 Repairs............................................................................................................................................... 9

2Confirmation ........................................................................................................................................ 10

3Technical Data ..................................................................................................................................... 11

3.1 Use of the Device for the Intended Purpose.................................................................................... 11

3.2 Emissions......................................................................................................................................... 12

3.3 Maximum Load ................................................................................................................................ 13

3.4 Receptacle Volume.......................................................................................................................... 13

3.5 Feed Grain Size............................................................................................................................... 13

3.6 Degree of Protection........................................................................................................................ 14

3.7 Dimensions and Weight................................................................................................................... 14

3.8 Required Floor Space...................................................................................................................... 14

3.9 Rated Power.................................................................................................................................... 14

4Packaging, Transport and Installation .............................................................................................. 15

4.1 Packaging........................................................................................................................................ 15

4.2 Transport.......................................................................................................................................... 15

4.3 Temperature fluctuations and condensed water ............................................................................. 15

4.4 Conditions for the Installation Site................................................................................................... 15

4.5 Installation of the Device.................................................................................................................. 16

4.6 Insert tensioning rod ........................................................................................................................ 17

4.7 Connect the control unit................................................................................................................... 18

4.8 Wall mounting and bench arrangement of the control unit.............................................................. 19

4.9 Electrical Connection....................................................................................................................... 19

4.10 Type Plate Description..................................................................................................................... 20

5Operating the Device .......................................................................................................................... 21

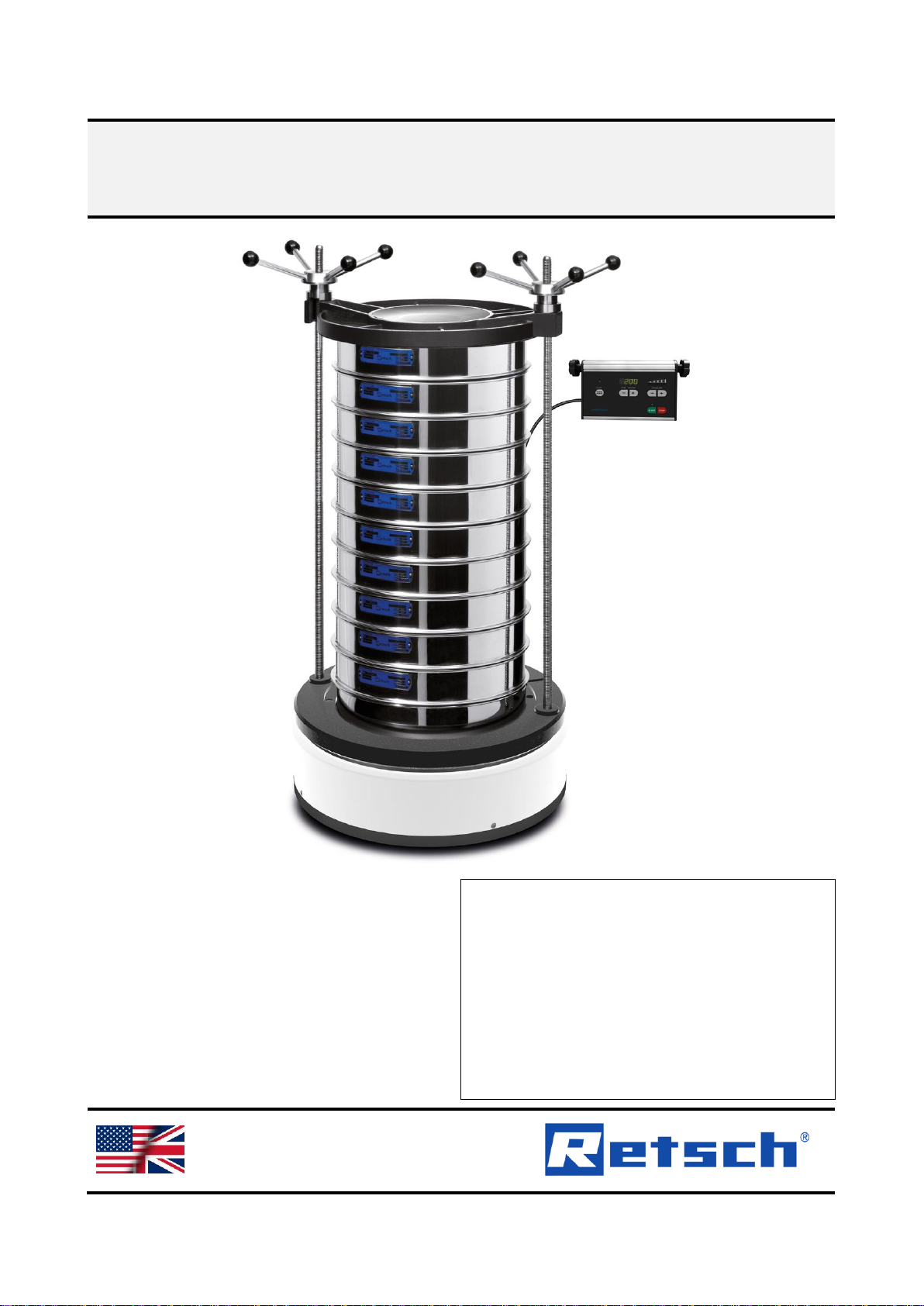

5.1 Views of the Instrument................................................................................................................... 21

5.2 Overview table of the parts of the device ........................................................................................ 22

5.3 Operating elements and displays .................................................................................................... 23

5.4 Overview Table of the Operating Elements and the Display........................................................... 23

5.5 Inserting and Clamping the Test Sieves.......................................................................................... 24

5.6 Operating the Device....................................................................................................................... 25

5.7 Switching On and Off....................................................................................................................... 26

5.8 Starting and stopping....................................................................................................................... 26

5.8.1 Starting......................................................................................................................................... 26

5.8.2 Stopping....................................................................................................................................... 26

5.9 Setting the sieve values................................................................................................................... 27

5.9.1 Timer............................................................................................................................................ 27

5.9.2 Amplitude..................................................................................................................................... 27

5.9.3 Interval......................................................................................................................................... 28

6Wet sieving........................................................................................................................................... 28

6.1.1.1................................................................................................................................................... 29

6.2 Required accessories ...................................................................................................................... 29

6.2.1 Preparation for wet sieving .......................................................................................................... 29