MAINTENANCE

ADDITION OF DISINFECTANT :

The control panel is equipped with an automatic system to determine the quantity of disinfectant.

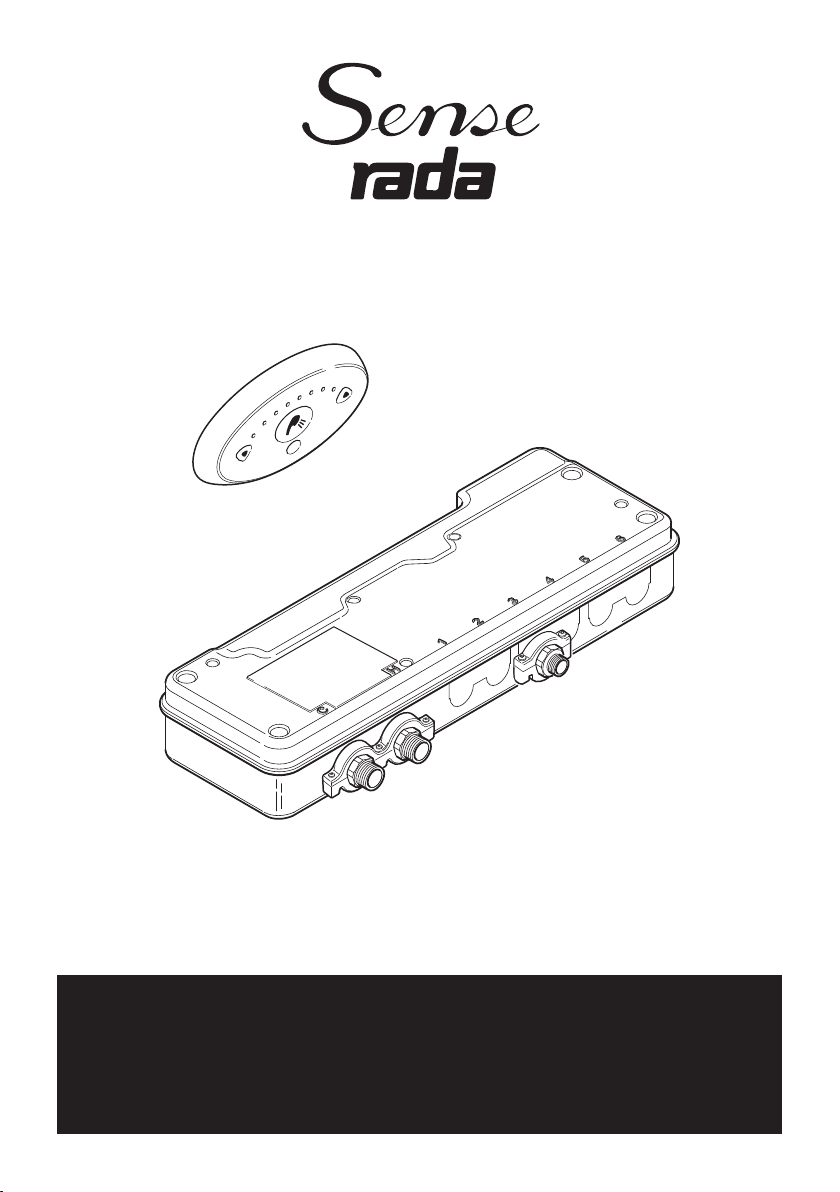

The disinfection system includes :

•1 lites tank receiving the disinfectant product.

•1X plunger with calibrated tube, located in the tank, and connected by a flexible going through the top of

the venturi (white plastic part).

•1 disinfection shower.

Dilution :

The mixing of water and disinfectant inside the disinfection shower is made in 2 stages :

First :

Manual dilution inside the tank.

Second :

The suction device (venturi) ensures a dosage of 10% of the aspirated product from the tank.

Exemple :

The disinfectant BFR 4.0 must be used with a final dilution of 0,4%.

1) Manual dilution inside the tank at 4%, that is 40ml of BFR 4.0 for 960ml of water.

2) Complementary dilution of 10% ensured with cold water by the suction device (venturi).

CLEANING OF THE CONTROL PANEL :

To clean the “rada sense” control panel, take the magnetic key and pass it in front of the infra red of the control

panel to desactivate it. (during 30 minutes) To reactivate the control panel, do the inverse operation.

Only use liquid products (liquid soap).

Don't use abrasive products like "scouring cream" to avoid scratches on the tub surface "Gelcoat".

Furthermore, to eliminate calcareous marks settled by water moving, we recommend to use the scaler (Gel Servex ).

Do not use liquid soap and the scaler (Gel Servex) on the control panel elements;

Rada sense mixer and whirlpool control.

6/7