BEFORE STARTING — Rotate the external pump shaft by

hand to prime the pump. Start the pump motor and check for

oil flow thru the oil sight or in the oil troughs. If oil is not

circulating, reverse the motor shaft rotation and recheck.

Internal pumps on YBX units do not require priming, but check

for oil flow through the oil sight after the unit has been started.

RECHECK OIL LEVEL — After operating the unit for 2 or 3

minutes, shut down and immediately recheck the oil level

before oil lines drain. This reading will indicate the true

operating oil level. Add oil, if necessary, to raise level to the

“full” mark on the dipstick.

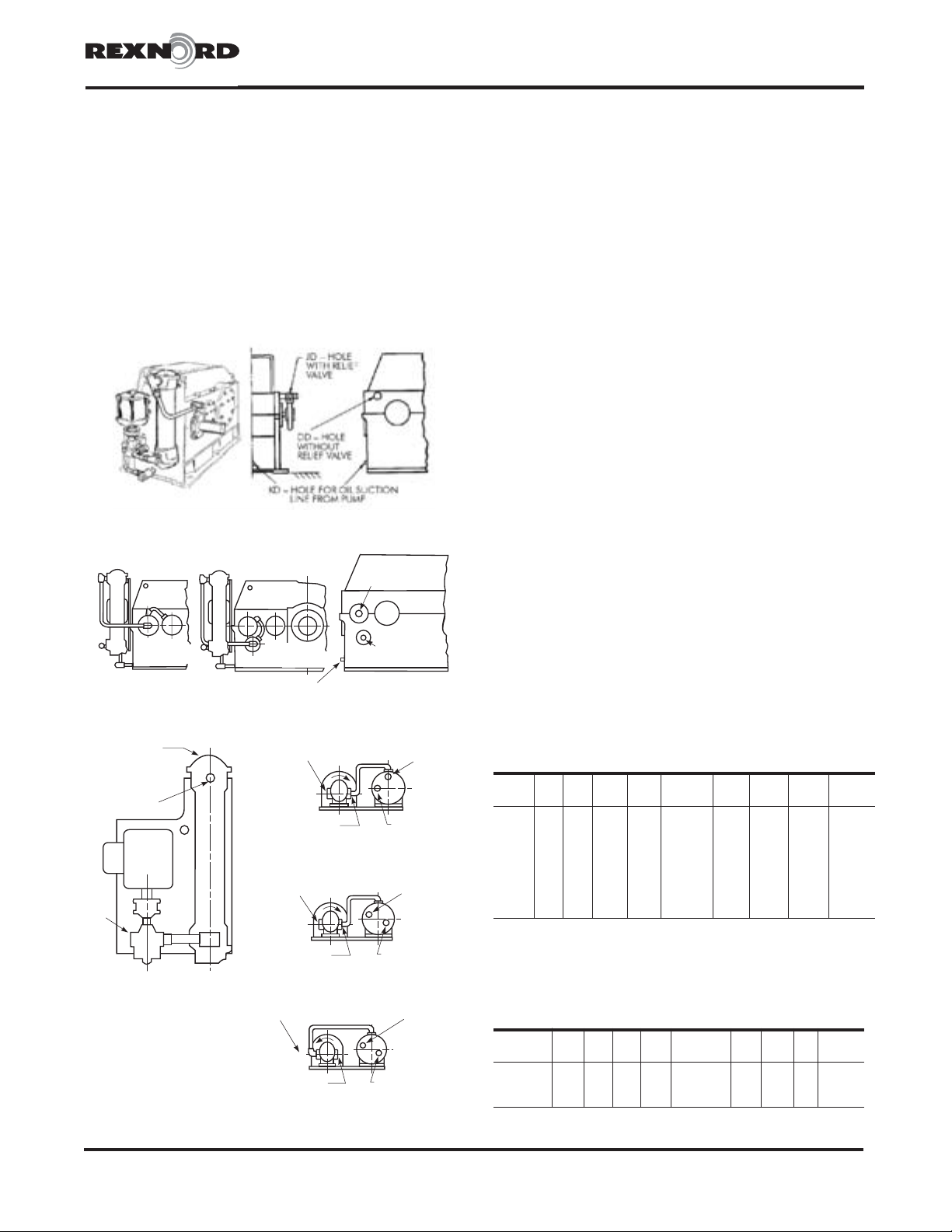

JET SPRAYS — Drives equipped with this system may be

identified by the oil piping shown in Figure 2. A jet of oil is

directed to the H.S. shaft bearings, while a spray of oil

lubricates the H.S pinion.

Check to see that an even spray of oil emerges from the nozzles

onto the pinion and that oil is flowing through the H.S bearings. If

not, disassemble the clogged portion and clean the oil passages

with a wire. Flush thoroughly to remove any contaminant.

Oil must be free of lint or any contamination that may clog the

lubrication nozzles or oil passages.

WATER FLOW — Be sure that all parts of the system are

clean and that the exchanger is full of fluid. Maintain the

specified rate of oil and water flow. Avoid excessive flow of

cooling water since this may cause tube failure through

erosion and may decrease cooling efficiency.

Add antifreeze per manufacturer’s specification to closed

water supply systems. However, note that antifreeze reduces

the rate of heat dissipation.

The additional thermal horsepower capacity provided by the

cooler is based on a 1:1 oil/water flow rate, a 55°F(31°C)

inlet temperature difference between oil and water,

90°F(32°C) inlet water temperature and maximum inlet water

pressure of 50 psig.

Adjust the water flow rate within the flow range shown on the

cooler or unit water circulation plate to maintain a reducer

operating temperature range of 140° to 160°F(60° to 71°C).

The minimum value of the range is for clean water at a

minimum velocity to prevent fouling of the tube bundle. For

brackish water, a flow rate of 2 times the minimum value is

required to prevent suspended solids from settling. The

maximum value of the range is based on a maximum velocity

to avoid erosion of the tube bundle.

MAINTENANCE

HEAT EXCHANGER — It is important that the inside parts are

kept clean. Inspect the exchanger periodically and clean

thoroughly. Inspect all tubes carefully for possible corrosion or

foreign material. Bleed the oil side of the cooler periodically if

air tends to collect in the system.

For open systems, drain vertical coolers by removing the two

zinc anodes and loosening the bottom bonnet. Disconnect and

drain the lines on horizontal open systems. Blow out all lines.

Heat exchangers are equipped with zinc anodes to minimize

galvanic corrosion. Inspect after first month of service and

periodically thereafter, depending on the severity of corrosion.

If 50% of the anode is used up, replace it.

Check the reducer oil level periodically. If it is ABOVE the

high level mark on the dipstick, have the oil analyzed for

water content. Moisture or water in the oil may indicate

that the heat exchanger is leaking. If so, replace the

exchanger immediately and change the oil.

EXTERNAL PUMP —Correct shaft alignment is essential;

check with a straightedge across the flanges of the coupling,

or use a feeler gauge between the faces of the coupling

halves at 90° intervals. The pump is a positive displacement

rotary type with a mechanical seal. Refer to manufacturer for

detailed maintenance.

INTERNAL PUMP — The lubricating pump on the 2000YBX2

exchanger cooled units is a positive displacement rotary type

manufactured at Falk. If maintenance is required, refer to the

Factory for detailed instructions.

OIL FILTER —If the filter is a Purolator, cleaning of the

element is accomplished by rotating the hand wheel several

turns once a week. Remove the filtering element and scrub

with a fiber bristle and a non caustic solvent at oil change

intervals. Flush out housing with solvent. If the filter is a

Marvel, follow the above element cleaning procedure, and

when reassembling, be sure that the “O” ring is properly

seated in the head groove.

JET LUBRICATION SYSTEM DISASSEMBLY —Disconnect

piping and remove the housing end covers. The oil manifold

with spray nozzles is attached to one end cover and will pull

free from the opposite cover. Refer to Figure 4.

JET LUBRICATION SYSTEM ASSEMBLY —Install all new

end cover gaskets. Align the nozzles in a horizontal plane

facing the centerline of H.S. pinion as shown in Figure 4.

MERCOID PRESSURE CONTROL SWITCH — The mercoid

switch is a sealed unit and should not be serviced. There is a

double adjustment for setting both “on” and “off” operating points.

RELIEF VALVE — This valve is pre-set at the factory and

normally does not require adjustment. However, rotating the

adjusting screw clockwise will reduce the opening pressure.

Accessories such as flow indicator, pressure gauges,

thermometers, heaters and pressure controls are sealed units.

If a malfunction occurs, return the sealed unit directly to the

manufacturer for repair or replacement.

Installation and Maintenance •Falk™ Gear Drive Type PC Pump and Cooler

(Page 2 of 3) All Sizes •Types Y, YF, YB, and YBX

Rexnord Industries, LLC, Gear Group148-931

3001 W. Canal St., Milwaukee, WI 53208-4200 USA Telephone: 414-342-3131December 1990