Service Instructions for No. 4 AC Solenoid Kit

Series 55,700 Disc Brakes

®

Brake Replacement Parts

P/N 8-078-945-05

effective 9/25/98

Important

Please read these instructions carefully

before servicing your Stearns brake.

Failure to comply with these instructions

could cause injury to personnel and/or

damage to property if the brake is

installed or operated incorrectly. For

definition of limited warranty/liability,

contact Rexnord Industries, Inc., Stearns

Division, 5150 S. International Dr., Cudahy

Wisconsin 53110, (414) 272-1100.

Caution

1. Installation or servicing shall be in

compliance with applicable local safety

codes including Occupational Safety

and Health Act (OSHA). All wiring and

electrical connections must comply with

the National Electric Code (NEC) and

local electric codes in effect.

2.To prevent an electrical hazard,

disconnect power source before

installing or servicing of the brake. If

power disconnect point is out of sight,

lock disconnect in the

off

position and

tag to prevent accidental application

of power.

3.The exterior surface of an operating

brake may be hot enough to cause

injury. Allow sufficient time for the brake

to cool before disassembly.

4. Do not operate brake with housing

removed. All moving parts should be

guarded.

5. After usage, the brake interior will

contain burnt and degraded friction

material dust.This dust must be

removed before servicing or adjusting

the brake.

DO NOT BLOW OFF DUST using an

air hose. It is important to avoid

dispersing dust into the air or inhaling

it, as this may be dangerous to your

health.

a) Wear a filtered mask or a respirator

while removing dust from the inside

of a brake.

b) Use a vacuum cleaner or a soft

brush to remove dust from the

brake.When brushing, avoid

causing the dust to become

airborne. Collect the dust in a

container, such as a bag, which can

be sealed off.

6. Installation or maintenance should be

performed only by qualified personnel

familiar with the construction and

operation of the brake.

7. For proper performance and operation,

only genuine Stearns parts should be

used for repairs and replacements.

Warning! Any mechanism or load held in

position by the brake should be secured

to prevent possible injury to personnel or

damage to equipment before any

disassembly of the brake is attempted or

before the manual release knob or lever is

operated on the brake.

Instructions

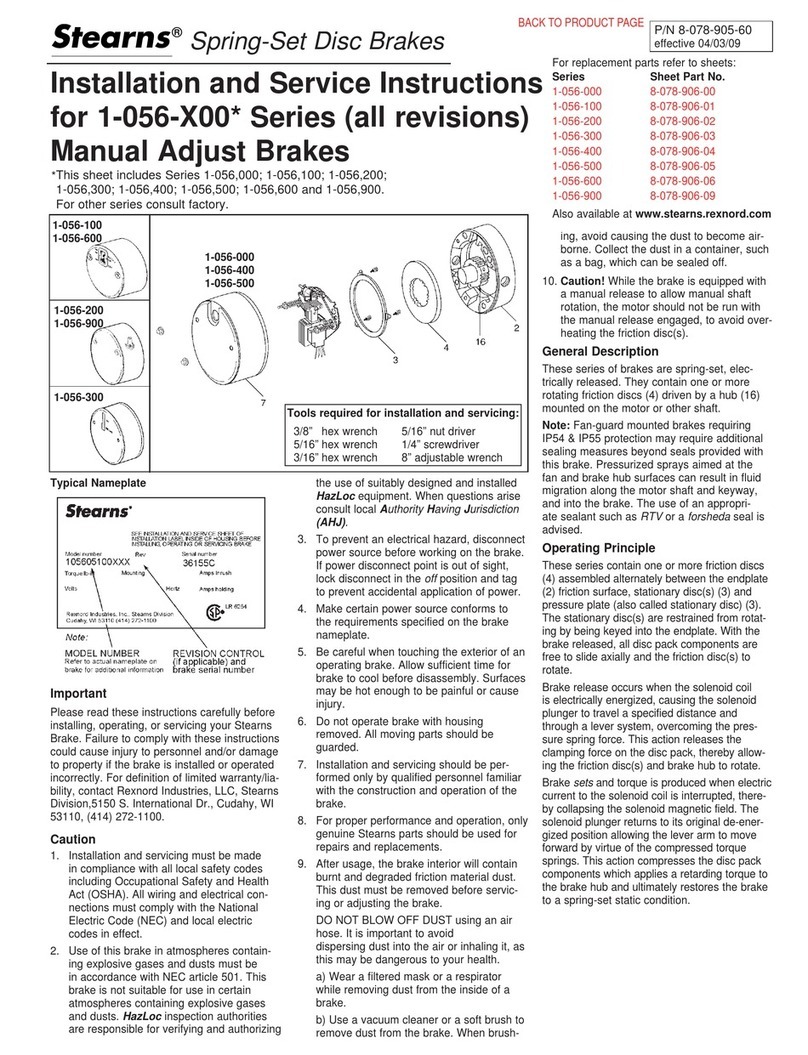

1. Remove housing (7) by unscrewing

nuts from the four mounting studs

(128) that protrude through the

reducer flange.

2. Grasp the coupler brake and motor as

a unit and pull free from the reducer.

3. Pull housing from the mounting studs

(128).These studs are threaded into

the C-face and should remain in place.

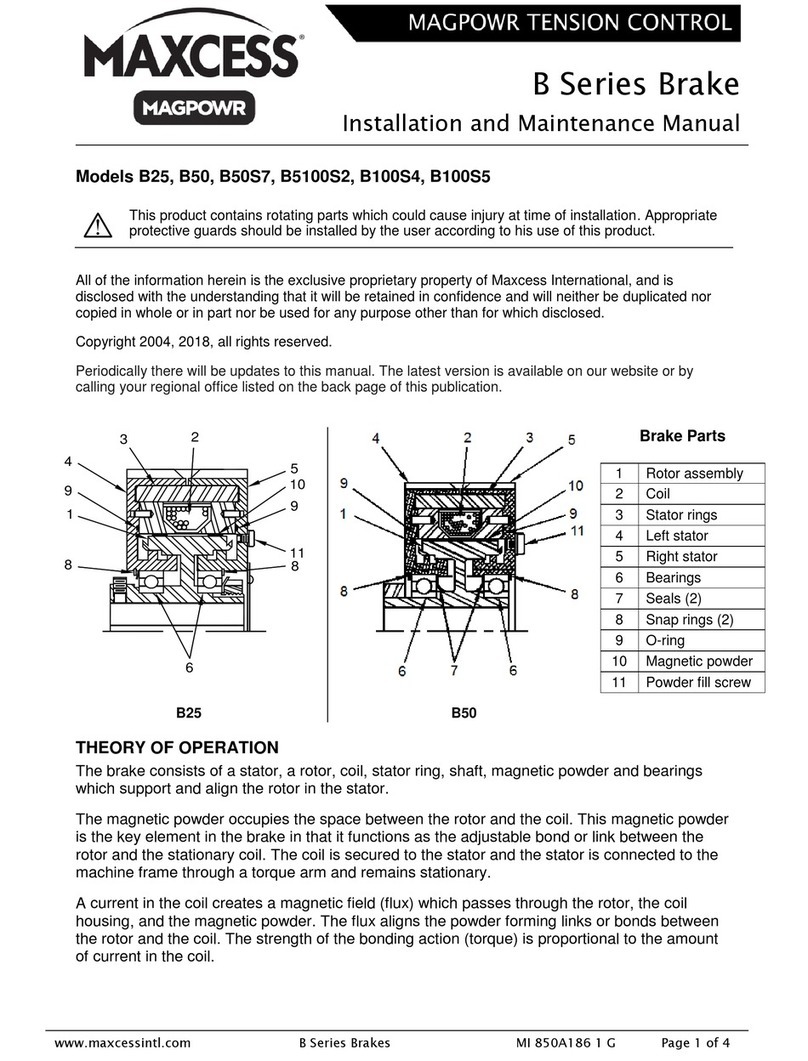

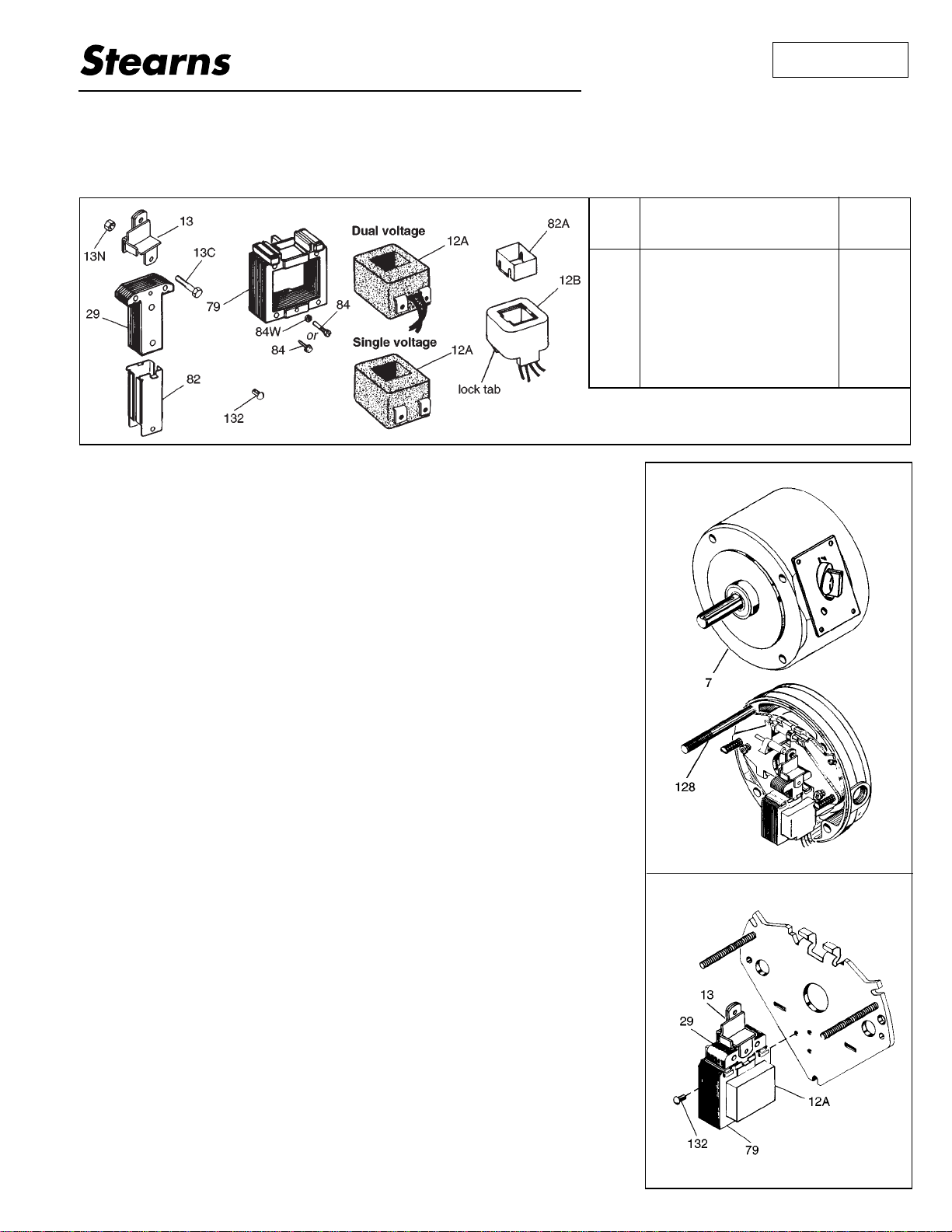

4. Solenoid replacement can be

accomplished without removing the

support plate from the brake.

5. Disconnect coil lead wires. Remove

three solenoid mounting screws (132)

to free solenoid frame (79). Note

mounting position.

29

13

79

13C

13N

132

Solenoid plunger

Solenoid link

Solenoid frame

Solenoid link cap screw

Solenoid link nut

Solenoid mounting screw

1

1

1

1

1

3

Item

No. Description of Parts

Included in Kit Quantity.

per

Kit