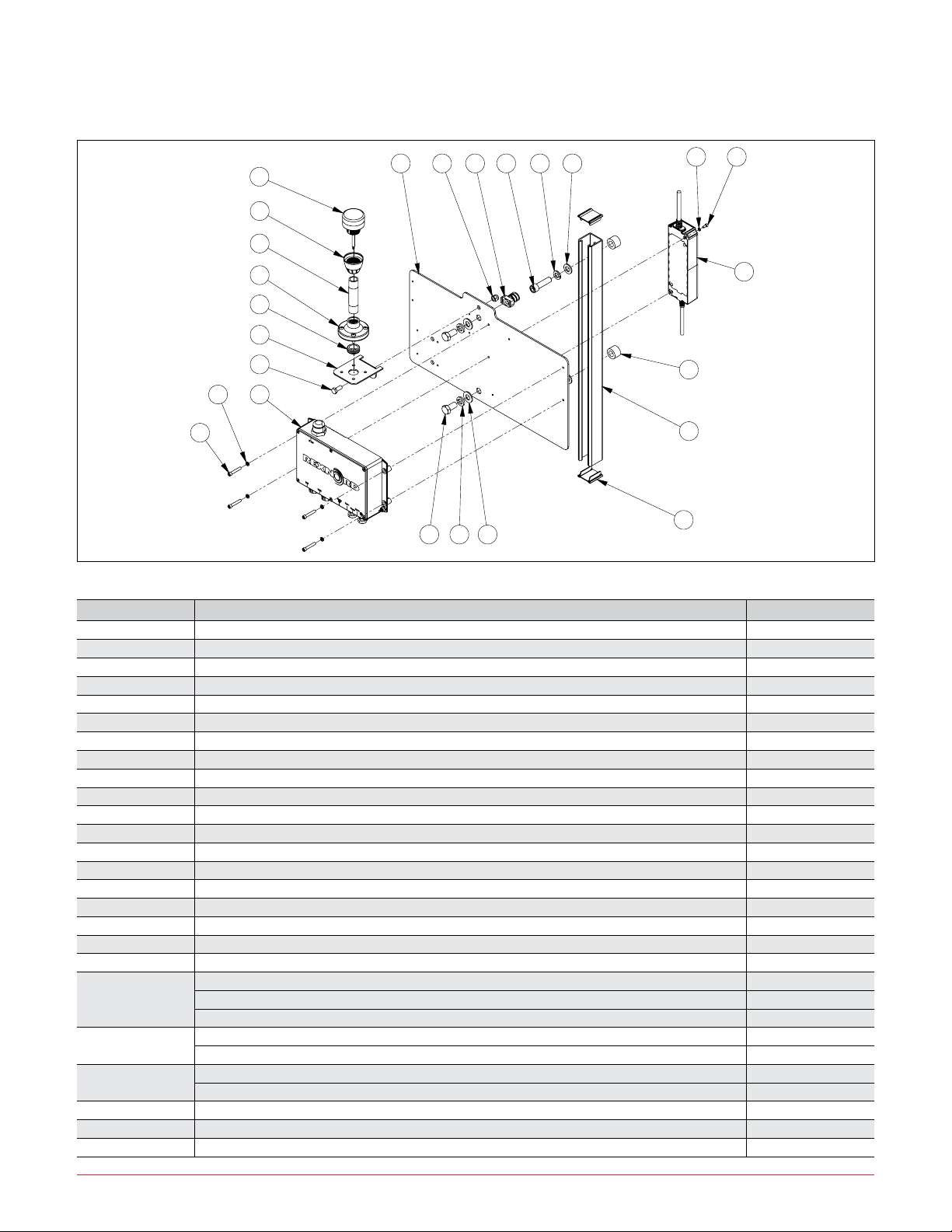

3

1446

4142

44 1

SEE NOTE 7

MOUNTING ITEM 1 TO

SHEET METAL

(OPTIONAL)

1

41

42

44 43

CABLE CLIP ASSEMBLY

451617

SEE NOTES 3 & 4

10795892 MONITOR KIT

(OPTIONAL)

60

61 62 63

* ITEM NOT SHOWN IN ASSEMBLY VIEWS

NOTES:

FASTENER TORQUES PER DRAWINGS 436155 (INCH) AND 436156 (METRIC)

1.

EXCEPT WHERE NOTED.

USE LOCTITE PIPE JOINT COMPOUND #30557 (PART NUMBER 10164926)

2.

OR EQUIVALENT ON ALL NPT PIPE JOINTS.

CABLE TIES (ITEM 17) TO BE INSTALLED WHERE NEEDED. DRILL 0.144" (#27) PILOT HOLE.

3.

CABLE TIES (ITEM 17) AND VIBRATION SENSOR (ITEM 3) MAY BE EPOXY

4.

MOUNTED IF PREFERRED, USING EPOXY (ITEM 21).

SEE DRAWING 110023894 FOR WIRING DIAGRAM.

5.

USE LOCTITE #242 THREADLOCKER (PART NUMBER 10154332) OR EQUIVALENT

6.

ON FASTENERS PER FMS 6.610 AS INDICATED.

MODBUS CONVERTER (ITEM 1) CAN BE LOCATED AS NEEDED.

7.

DRILL & TAP M8x1.25 MOUNTING HOLE.

MOUNTING POSTS (ITEM 13) ONLY USED ON 190-220V UNIT SIZES.

8.

ONLY THESE TWO ORIENTATIONS

ARE ACCEPTABLE FOR VIBRATION

SENSOR.

SLAVE ID: 40

SEE NOTES 4 & 6

(LOCTITE MTG SCREWS)

A

A

UNIVERSAL KIT BOM

ITEM

NO.

DESCRIPTION

QTY.

PART NO.

1

CONVERTER, MODBUS

1 10729698

2

ANDON LIGHT MODBUS MODIFIED

1 10674040

3

VIBRATION & TEMP SENSOR QM42VTQP MODIFD

1 10674039

4

EDGE-DEVICE, SERIAL, SED3 NO CELL

1 10782841

5

POWER-SUPPLY, PSU-SED503XYY KIT

1 10782845

6

CHANNEL 1-5/8"X1-5/8" SLOTTED, 32 IN, PRE-GALVANIZED

1 10791225

7

BRACKET SWITCH, ANDON LIGHT, 465A

1 10674013

8

BUSHING PUSH-IN RUBBER

1 10714028

9

BUSHING PIPE - PIPE MTG FLANGE

1 10609128

10

CONDUIT NIPPLE, ELECTRICAL 0.500-14 NPT X 3.50, GALVANIZED

1 10667340

11

ADAPTER PIPE - ANDON

1 10609126

12

MOUNTING PLATE, UNIVERSAL KIT, V3 EDGE DEVICE

1 10817916

13

MOUNTING POST, 190V-220V

2 10181094

14

RTD SUMP W/3-PIN CONNECTOR, 3.000"

1 10786580

15

END CAP FOR UNISTRUT, METAL, P1280EG

2 10606019

16

MOUNT, CABLE TIE, SS

8 10743680

17

CABLE TIE, HI-TEMP

8 10714805

18 *

SERIAL CABLE M12 F - M12 M, 5.0M, MOLDED

1 10738998

19 *

SERIAL CABLE M12 F - M12 M, 2.0M, MOLDED

2 10738996

20 *

SERIAL CABLE Y 2XM12 F TO M12 M, 0.25M

2 10739001

21 *

EPOXY, 2 PART DEVCON PLASTIC WELDER

1 10724955

22 *

LABEL QR CODE

1 10617071

23 *

BOX CARBON WALL 28X15X12

1 10804807

CONTENTS OF HARDWARE KIT 10818153

30

HEX HEAD CAPSCREW, 0.312-18UNC x 0.750", Gr.5, ZP

1 10063527

31

LOCKNUT, 0.312-18UNC, ZP

1 10064025

32

SOCKET HEAD CAPSCREW, #12-24UNC x 1.250", ZP

4 10812644

33

LOCKWASHER, #12, ZP

4 10812656

34

HEX HEAD CAPSCREW, 0.500-13UNC x 1.000", Gr.5, ZP

2 10063518

35

FLAT WASHER, 0.531 ID X 1.062 OD, 0.095 THK., ZP

2 10064172

36

LOCKWASHER, 0.500", ZP

2 10018201

37

CHANNEL NUT W/ SPRING, 1-5/8" SERIES, 0.500-13UNC

2 10605982

38

SOCKET HEAD CAPSCREW, M12x1.75 x 30, 8.8

2 10097296

SOCKET HEAD CAPSCREW, M12x1.75 x 45, 8.8

2 10097095

SOCKET HEAD CAPSCREW, 0.312-18UNC x 0.625"

2 10063413

39

FLAT WASHER, 13mm ID X 24mm OD X 2.5mm THK. (M12)

2 10093492

FLAT WASHER, 0.336 ID X 0.735 OD, 0.044 THK., 316SS

2 10219114

40

LOCKWASHER, M12, ZP

2 10084705

LOCKWASHER, 0.312", ZP

2 10064086

41

HEX HEAD CAPSCREW, M8x1.25 x 16, 8.8, ZP

1 10084648

42

LOCKWASHER, M8, ZP

1 10084708

43

HEX NUT, M8x1.25, ZP

1 10084703

44

HOSE CLAMP, Ø0,750", GALVANIZED

1 10741758

45

DRIVE SCREW ROUND HEAD, #8 X 0.375, ZP

8 10066024

46

PIPE BUSHING, 1.000-11.5 MP x 0.500-14 FP, ZP

1 10065334

PIPE BUSHING, 1.250-11.5 MP x 0.500-14 FP, ZP

1 10065336

PIPE BUSHING, 2.000-11.5 MP x 0.500-14 FP, ZP

1 10705867

47

SOCKET HEAD CAPSCREW, #8-32UNC X 0.375"

2 10063426

48

LOCKWASHER, #8, ZP

2 10064089

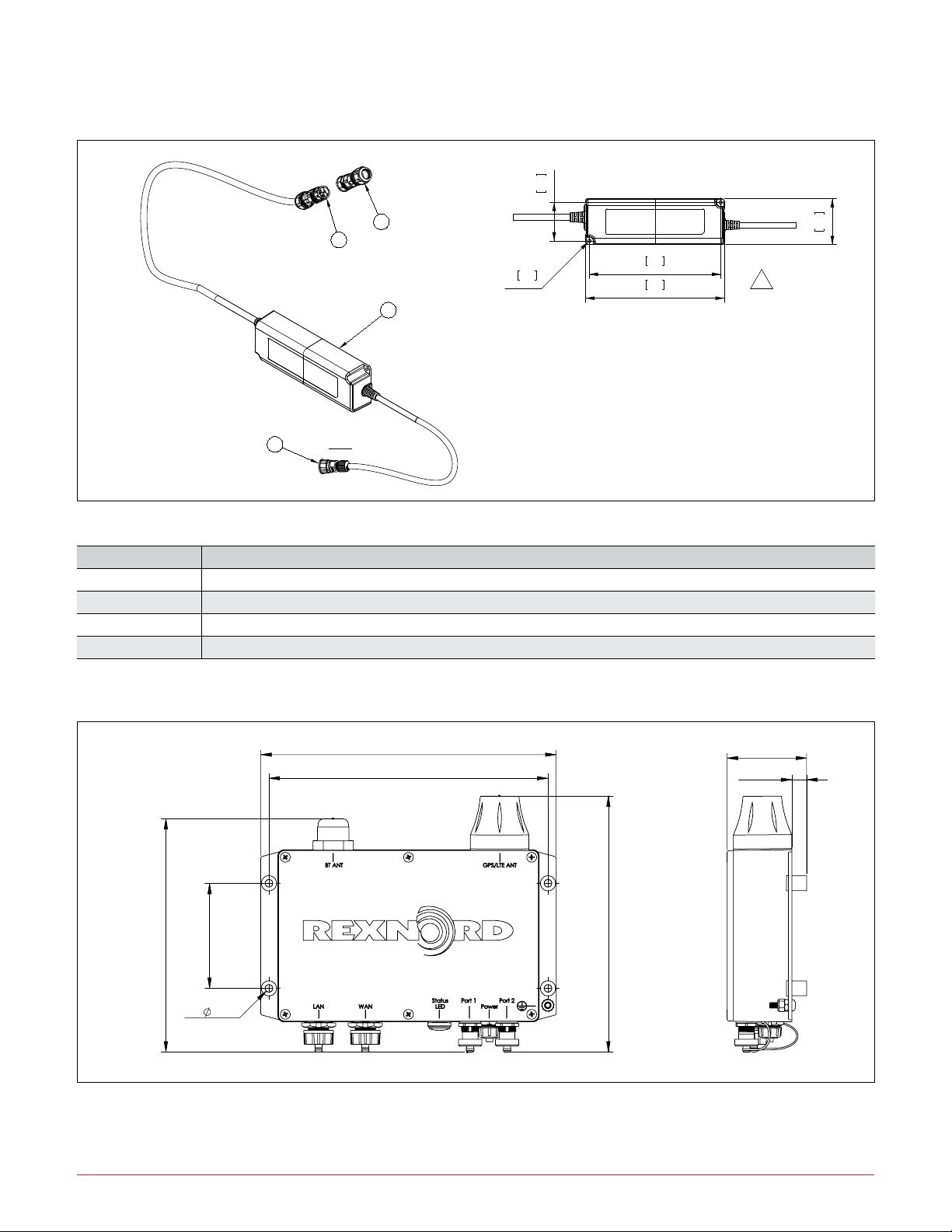

CONTENTS OF MONITOR KIT 10795892 (MONITOR KIT IS OPTIONAL)

60

MODBUS RTU MONITOR ASSY

1 10783609

61

SOCKET HEAD CAPSCREW, #10-24 x 0.750

4 10063433

62

FLAT WASHER, 0.219 ID X 0.500 OD, 0.049 THK.

4 10018205

63

LOCKWASHER, #10, ZP

4 10018202

64 *

SERIAL CABLE Y 2XM12 F TO M12 M, 0.5M

1 10739002

G

8

H

J

K

L

M

F

E

D

C

B

A

7

6

5

4

3

2

1

9

10

11

12

9

1

2

3

4

5

6

7

8

10

11

12

C

F

M

L

K

J

H

G

E

D

13

14

15

16

16

15

14

13

A

B

11-17-2020

.

.

KL

.

. .

A

THIS DOCUMENT CONTAINS CONFIDENTIAL/PROPRIETARY INFORMATION OF REXNORD INDUSTRIES, LLC.

NEITHER RECEIPT NOR POSSESSION THEREOF CONFERS ANY OWNERSHIP INTEREST IN RIGHT TO

REPRODUCE OR USE, OR DISCLOSE IN WHOLE OR IN PART, ANY SUCH INFORMATION WITHOUT

WRITTEN AUTHORIZATION FROM REXNORD INDUSTRIES, LLC. IT IS SUBJECT TO RETURN UPON DEMAND.

THESE COMMODITIES, TECHNOLOGY, OR SOFTWARE ARE SUBJECT TO THE UNITED STATES

EXPORT REGULATIONS. DIVERSION CONTRARY TO U.S. LAW AND OTHER RELEVANT EXPORT CONTROLS IS PROHIBITED.

SOLIDWORKS DRAWING

DO NOT CHANGE MANUALLY

DATE

CHKD

SYM

SCMS TIER 1010, V3

10-28-2020

D. JASKIE

N. ZASTROW

K. LEICK

ENGINEER

MFG./PUR.

DATE

DESIGNER

REV.

UNIT:

TITLE:

SIMILAR TO

SCALE

DWG. NO.

www.rexnord.com

REXNORD INDUSTRIES, LLC

110022851

1:4

110023960 Drawing

ASSY UNIVERSAL KIT

SIZE

A1

.

A

RESTRICTED

. .

..

FINISH MASS

ROUGH MASS

HEAT TREATMENT

MATERIAL

RGH. PART NO.

.

.

.

.

.

ASSY UNIVERSAL KIT

PART NAME

SHT. 1 OF 2

CLASSIFICATION=

.

SAP PART NO.

- UNLESS OTHERWISE SPECIFIED -

DIMENSIONS ARE IN MILLIMETERS

DIMENSIONS IN BRACKETS '[ ]'

ARE IN INCHES