II&E2020_11 Hi-Finity electric lock: Installation and testing –Manual for the installer & electrician 2

Contents

1Safety information.........................................................................3

2Description of the Hi-Finity electric lock............................................3

2.1 Parts list..............................................................................................................3

2.1.1 Choosing the right assembly ..........................................................................4

2.1.2 Assembly accessories for electric lock ...........................................................4

2.1.3 Additional/other finishing parts for pre-motorised element..............................7

2.1.4 Finishing parts for conversion to a motorised element....................................8

3Assembly and installation...................................................................9

Legend 9

Assembly / installation order............................................................................................9

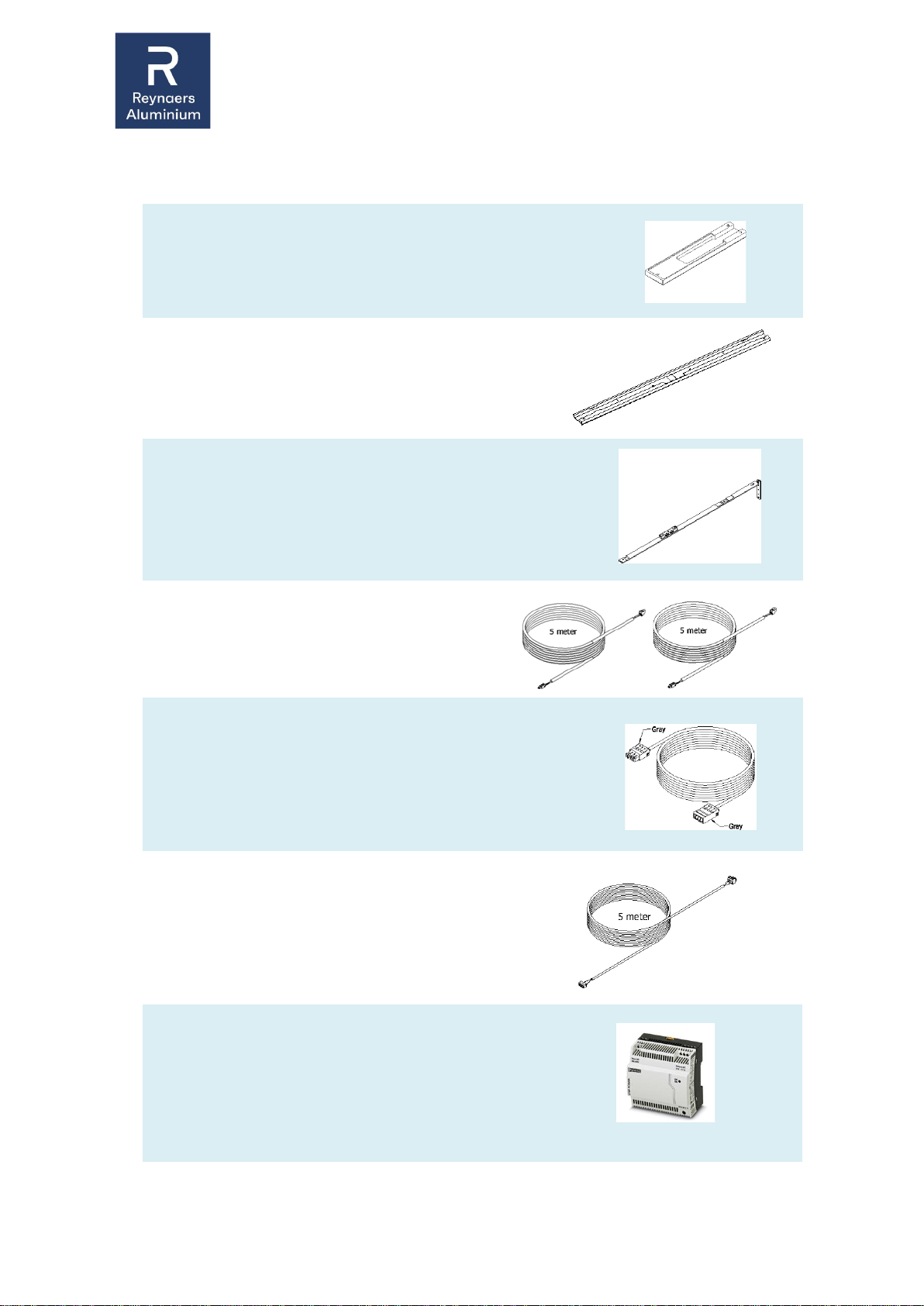

3.1 Workshop preparations.......................................................................................9

3.1.1 Standard electric lock .....................................................................................9

3.1.2 Electric lock upgrade ready ..........................................................................11

3.1.3 Electric lock upgrade to motorization............................................................12

3.2 Onsite electric connections...............................................................................13

3.2.1 Power connection.........................................................................................13

3.2.2 Using Motor cable.........................................................................................13

3.2.3 Pre-wired Electric Cabinet ............................................................................13

3.3 Onsite completion mechanical installation........................................................14

3.3.1 Assembly of the connection rod....................................................................14

3.3.2 Fine-tune the rod ..........................................................................................14

3.3.3 Change operandi modus ..............................................................................15

3.4 Testing..............................................................................................................15

4LIABILITY AND GUARANTEE............................................................16

5DISMANTLING AND REMOVAL.........................................................16

6FAQ 17

7Technical specifications....................................................................18

7.1 Electric drawings...............................................................................................18

7.2 Connecting the alarm output.............................................................................21

© 2020 by Reynaers Aluminium. All rights reserved.

Statement of Conditions

In the interest of improving internal design, operational function, and/or reliability,

Reynaers Aluminium reserves the right to make changes to the products described in this

document without notice. Reynaers Aluminium does not assume any liability that may

occur due to the use or application of the product(s) or circuit layout(s) described herein.