Page 6 User Guide: RFM5104/14 Predictive Maintenance System User Guide

IN012F13 www.RFMicron.com

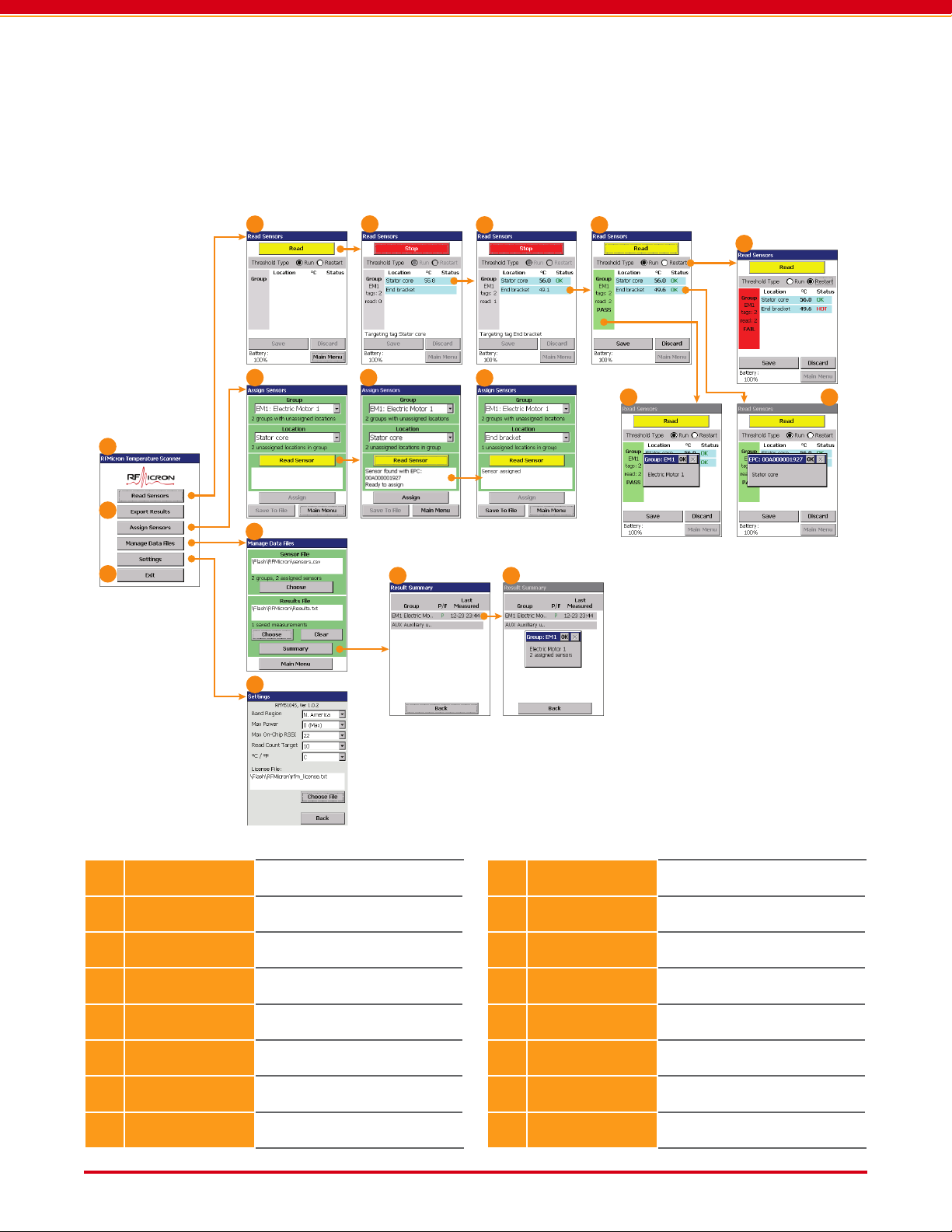

3. USING THE SYSTEM

3.1. Identifying and Organizing Sensors

RFMicron’s wireless, battery-free temperature

sensors are uniquely identiable by an Electronic

Product Code (EPC) stored in each sensor’s mem-

ory. Because the EPC does not, by itself, indicate

where the sensor is installed or what device it is

monitoring, each sensor must be registered and

assigned within the Temperature Scanner soft-

ware. A meaningful location description for each

installed sensor is very helpful.

Multiple sensors can be associated with each

other in groups. Sensor groups can be used to

organize sets of sensors by the equipment or

machine they are monitoring, or sensors can be

grouped according to which sensors are visible to

the reader from a particular reading location.

Sensor locations and group denitions are stored

in a text le called the SENSOR FILE. The SENSOR

FILE employs a comma-separated-value (CSV)

format and can be edited in a spreadsheet or

text editor application. For example, various

location and group descriptions can be added

to the original SENSOR FILE to speed the sensor

installation and assignment process.

When Temperature Scanner reads the EPC ID

code from a sensor, it uses the information in the

SENSOR FILE to display its location description

and group descriptions.

3.2. Temperature Thresholds

In addition to displaying the temperature re-

ported by installed sensors, Temperature Scan-

ner also compares the temperature to alarm

thresholds set by the user. When the measured

temperature of a sensor exceeds a threshold, a

warning is displayed on the screen, where the

sensor is shown as failing the temperature test.

Two thresholds are dened for each sensor.

These thresholds are named according to termi-

nology associated with electric motors but can

be used for any purpose by the user. The RUN

THRESHOLD is the temperature limit that the

motor or equipment should not exceed during

normal operation. The RESTART THRESHOLD is

typically a higher temperature limit that the

equipment can not exceed without risking ther-

mal damage to the equipment itself.

For motors, the RESTART THRESHOLD alarm is

calculated as the motor’s electrical insulation

thermal limit, minus the typical heat increase of

restarting that motor in that particular installa-

tion, minus 30 °C to 40 °C to account for the dif-

ference in temperature between the motor core

and the measurement point where the sensor

is located. The motor’s restart heating can be

measured by recording the motor’s temperature

increase immediately before stopping and then

after restarting the motor.

NOTE: If Run and Restart alarms don’t apply

to your application, feel free to treat these

as two independent alarm thresholds.

3.3. Preparing Sensors for Use

The rst step to using the Predictive Mainte-

nance System is to decide where sensors will be

installed, how sets of sensors will be grouped

together, and what their RUN THRESHOLD and

RESTART THRESHOLD should be. For example,

two sensors might be placed on a particular elec-

tric motor, one on the stator core and one on the

bearing cover to measure bearing temperature.

The stator sensor might have a RUN THRESHOLD

and a RESTART THRESHOLD of 55 and 90 °C, and

the bearing sensor might have a RUN THRESHOLD

and a RESTART THRESHOLD of 45 and 50 °C. Since

the two sensors are measuring dierent locations

on the same machine, they might be added to a

single group.