Lambda beam user manual 3.3. LASER OPERATION

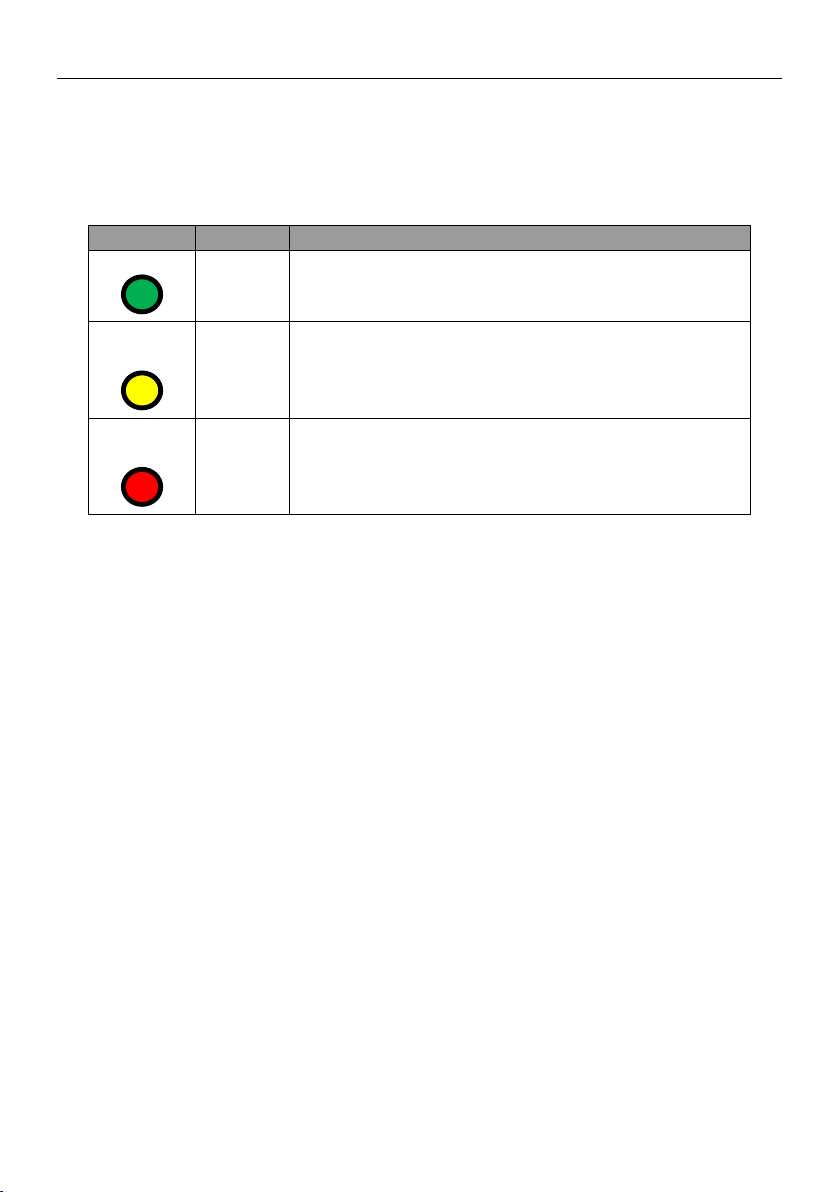

Status Indicators

The laser module includes two light emitting diodes (LEDs) to indicate the laser status:

LED Status Description

POWER On

O

Key switch o, interlock open or switched o via USB

Power supply not connected

KEYLOCK On Key switch o, interlock open or switched o via USB

O Key switch on and interlock closed (and switched on

via USB if connected to computer)

Flashing Error

EMISSION On Laser active, emission possible

(depending on selected output power)

O Laser inactive

Flashing 5 second delay before activating laser

3.3 Laser operation

In order to turn the laser on without using a computer or remote control, please:

1. Connect the system as described in the previous section.

2. Select the modulation mode using the switch (continuous wave (CW) /transistor-

transistor logic (TTL) / ANALOG) on the back side of the controller. Changing the

modulation mode is only possible while the key switch is in the OFF position.

3. For TTL or ANALOG modulation mode, please apply a voltage to the modulation

input (BNC connector). Note that even with an input voltage of 0 V, a small amount

of laser radiation can be emitted.

4. Close the interlock and turn the key switch to the ON position. The laser will start

with a 5 s delay (as required by CDRH regulation ). Once the laser is active, the EMIS-

SION indicator is lit.

For safety reasons, the key lock is activated when you connect the laser to power, even

if the key switch is in the ON position. To start the laser, turn the key switch o and on

again.

The Lambda beam series can also be controlled via USB as described in chapter 4.

7