Dehumidifier • For HVAC Installer Only

69-2298—01 4

Place the dehumidifier on supports to raise the

base of the unit. Do not place the dehumidifier

directly on structural building members without

vibration absorbers or unwanted noise may result.

The dehumidifier may be suspended from structural

members by supporting the entire base of the unit

via cross members, rigid frame, or the like. Do

not hang the dehumidifier from the cabinet.

Remember to place a drain pan under the unit if

it is suspended above a finished area or above an

area where water leakage could cause damage.

4.1D Sizing Chart

*This sizing chart is based on extreme climates where

Rh levels are between 70 and 90% outdoor Rh. For

less extreme climates then larger homes can be

adequately served. Actual requirements may vary.

4.2 Electrical Requirements

Dehumidifier Capacity Required to

Maintain Desired Indoor Rh*

Home Size

(square

feet)

60% Indoor

Rh

55% Indoor

Rh

50% Indoor

Rh

Pints/day Pints/day Pints/day

2080 49-54 55-58 71-78

2600 61-68 65-72 90-97

3120 75-82 79-86 95-110

WARNING: Installation must be performed

by a qualified service technician and must

comply with local codes. Remove power to

the device before installing or servicing the

device. Failure to connect the device

according to these instructions may result in

damage to the device or the controls.

The dehumidifier plugs into a common grounded

115VAC outlet. The device draws 6.3 Amps under

normal operating conditions. If used in an area

which may become wet, a ground fault interrupter

(GFI) protected circuit is recommended.

IMPORTANT: Do not install the humidistat

where it may not accurately sense the relative

humidity such as near HVAC supply registers,

near exterior doors, on an outside wall, near

a window, or near a water source.

Refer to Section 6 for typical hookup diagrams.

Some of the control wires leaving the dehumidifier

may not be used with certain installations and

should be left unconnected with wire nuts taped

onto the stripped ends for safety.

4.3 Condensate (Water) Removal

The dehumidifier removes a large amount of moisture

from the air and the device must be connected to a

drain line that will carry away the excess water. A

trap in the drain line is recommended and may be

required by some local codes.

The drain line should be connected to the 3/4"

male pipe thread adaptor on the front of the

dehumidifier.

Care should be taken to install the drain line with

a continuous slope of 1" per 10' to assure proper

water removal.

4.4 Ducting

IMPORTANT: When connecting ventilation

duct, remove the label and 6" round

insulation plug from the ventilation duct

opening. If not using ventilation feature,

leave the insulation intact.

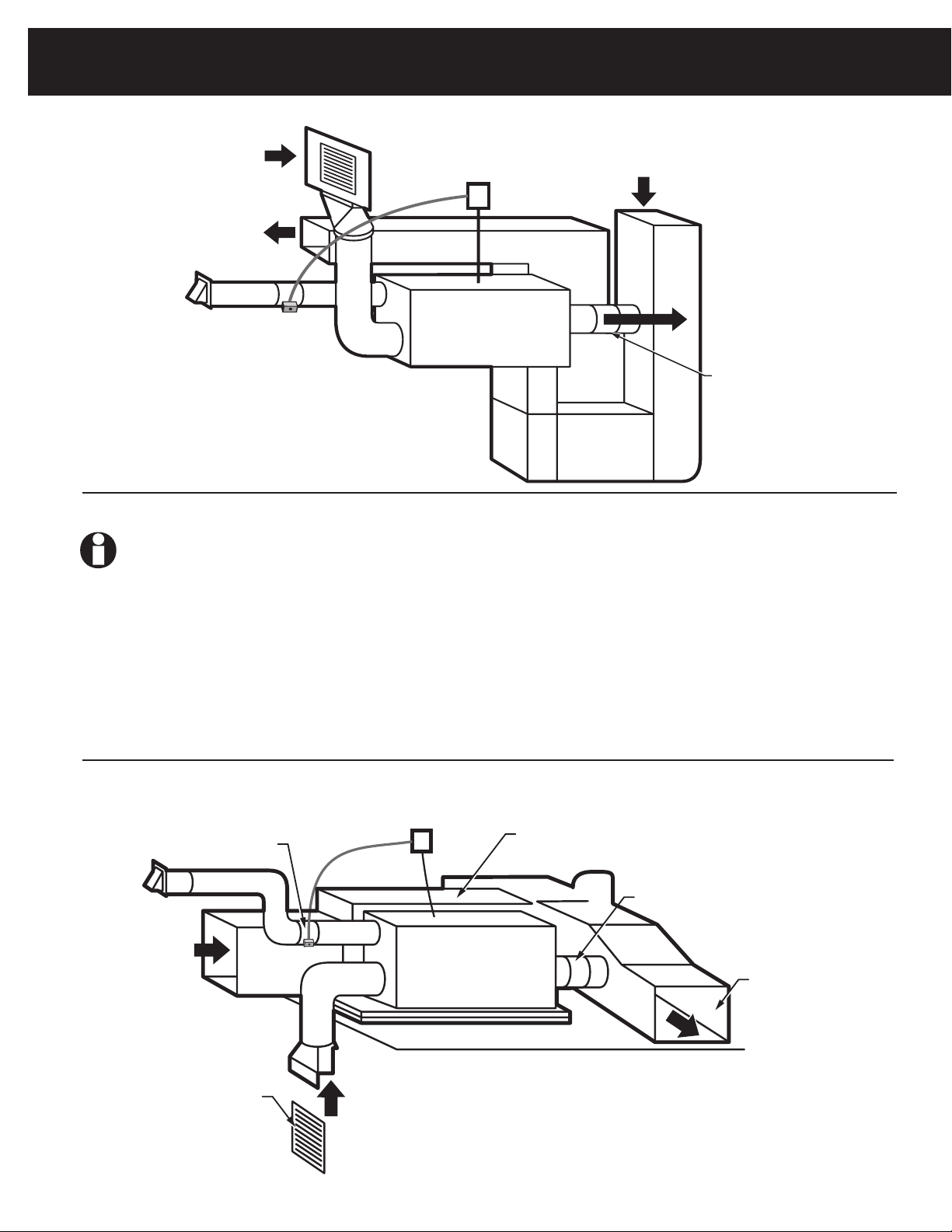

For the ideal installation, draw air from the central

part of the home and return it to the isolated areas

of the home like the bedrooms, den, utility room, or

family room. See Figure 2. Alternative installation

option can be completed by drawing air directly

from the return ducting and distributing through

the supply air to the home.

Another installation option is ducting directly from

the return and distributing directly back into the

system's return. See Figure 3. Fresh air ventilation

is optional and does not have to be ducted in order

for the dehumidifier to properly function.

IMPORTANT: DO NOT draw air directly from

the kitchen, laundry, or isolated basement.

Air may be drawn from a basement that is open

to the home. All flexible ducting connected to the

dehumidifier should be UL listed.

A short piece of flexible ducting on all dehumidifier

duct connections is recommended to reduce noise

and vibration transmitted to rigid ductwork in the

structure. Ducting the dehumidifier as mentioned

requires consideration of the following points: