Rheem RHP-5207C Series Technical Document

Other Rheem Water Heater manuals

Rheem

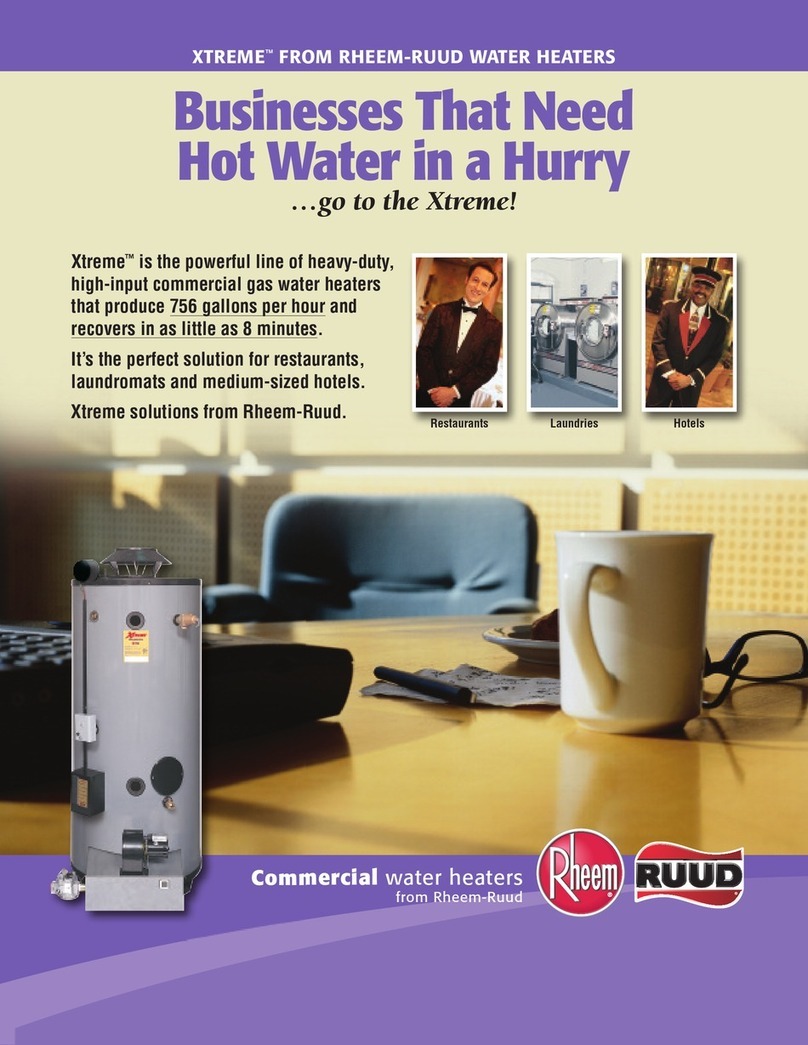

Rheem XtremeTM GX90-500 User manual

Rheem

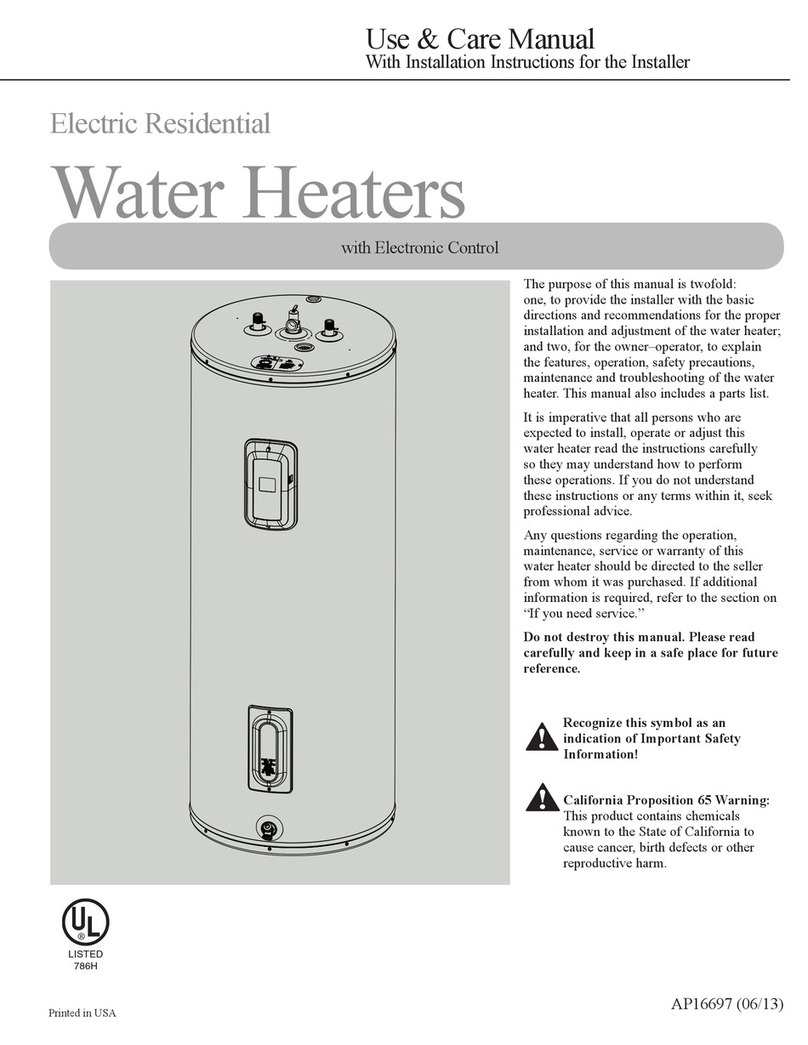

Rheem Ruud 6 KW THRU 54 KW User manual

Rheem

Rheem 82VP30 User manual

Rheem

Rheem 120 Volt User manual

Rheem

Rheem Gas Heavy Duty Water Heater Models 265 Litre and 275... Technical Document

Rheem

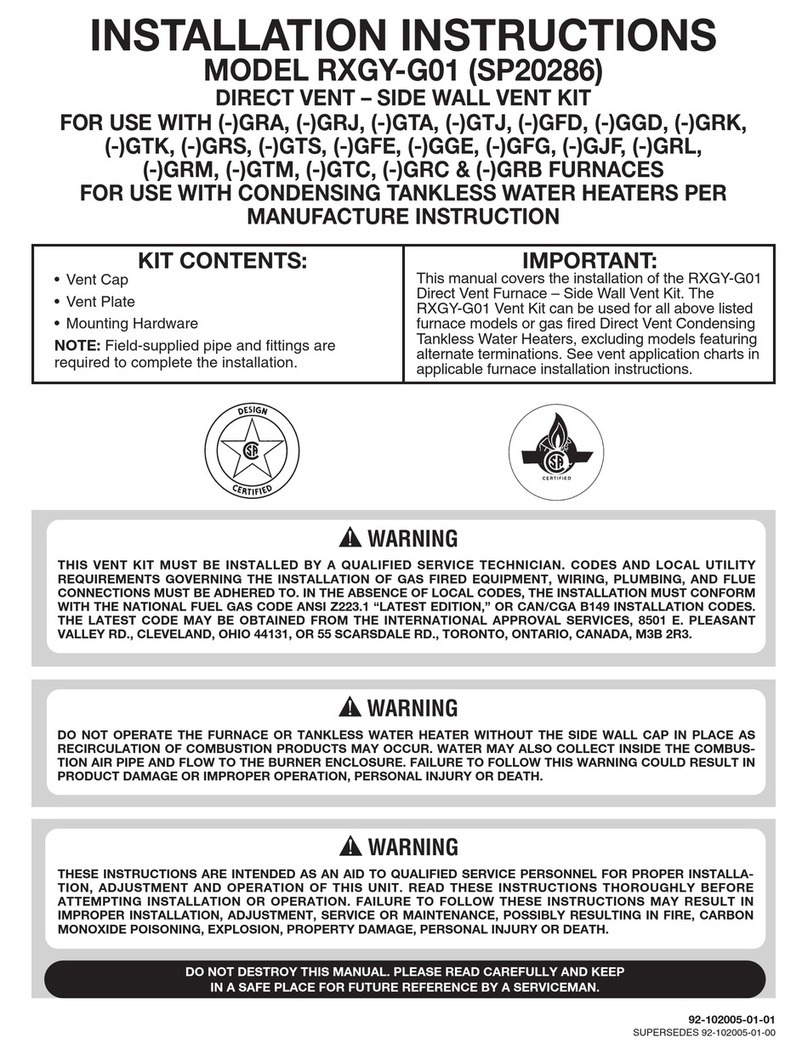

Rheem RXGY-G01 User manual

Rheem

Rheem Iconic RTGH-S11i User manual

Rheem

Rheem RUUD Electric Commercial Water Heater User manual

Rheem

Rheem 871018 Operating instructions

Rheem

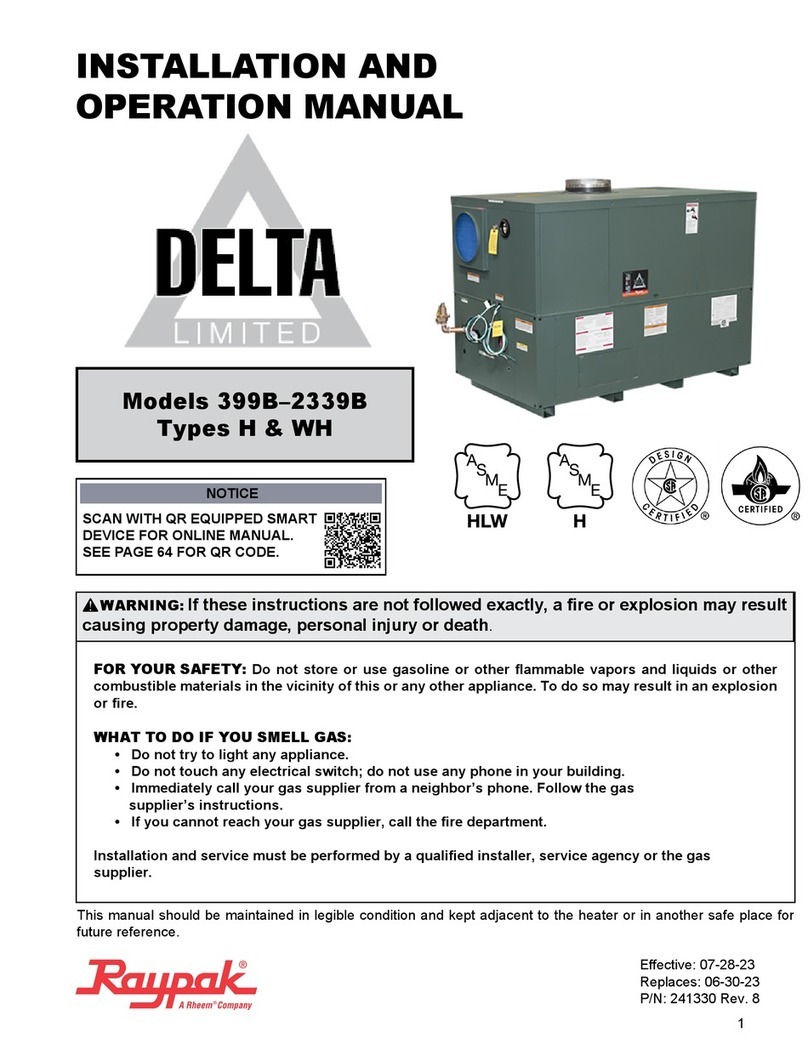

Rheem Raypak 408A User manual

Rheem

Rheem Richmond RMTGH-95DVLP User manual

Rheem

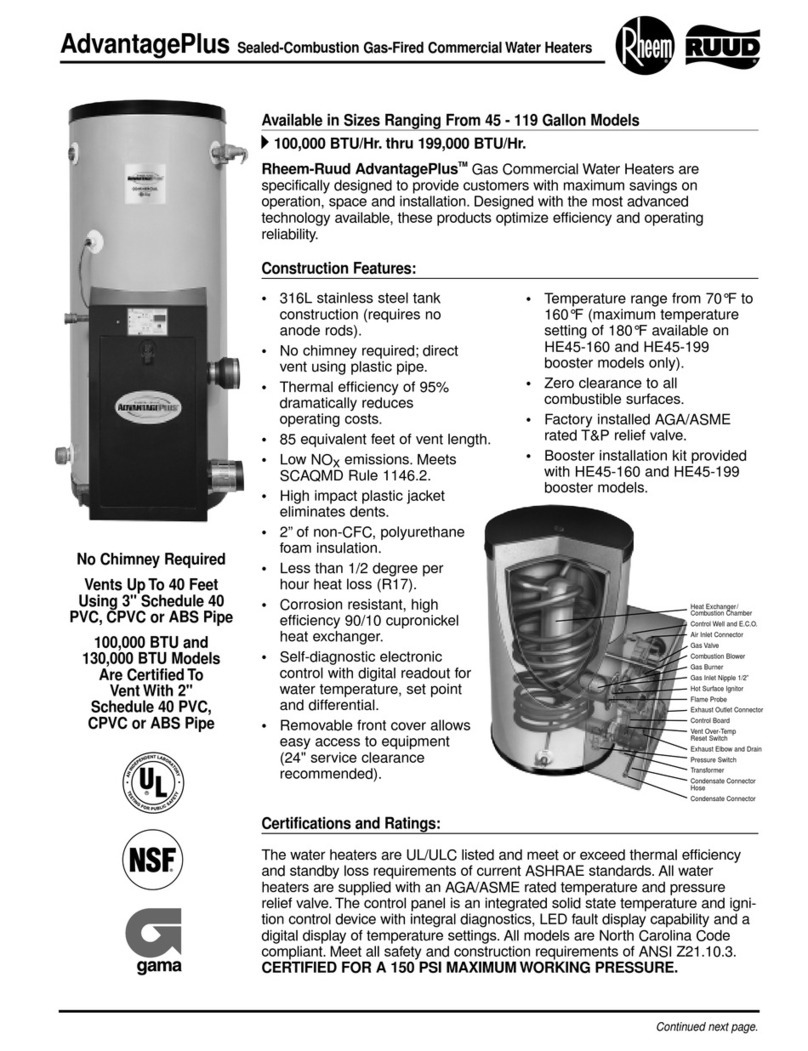

Rheem 000 BTU User manual

Rheem

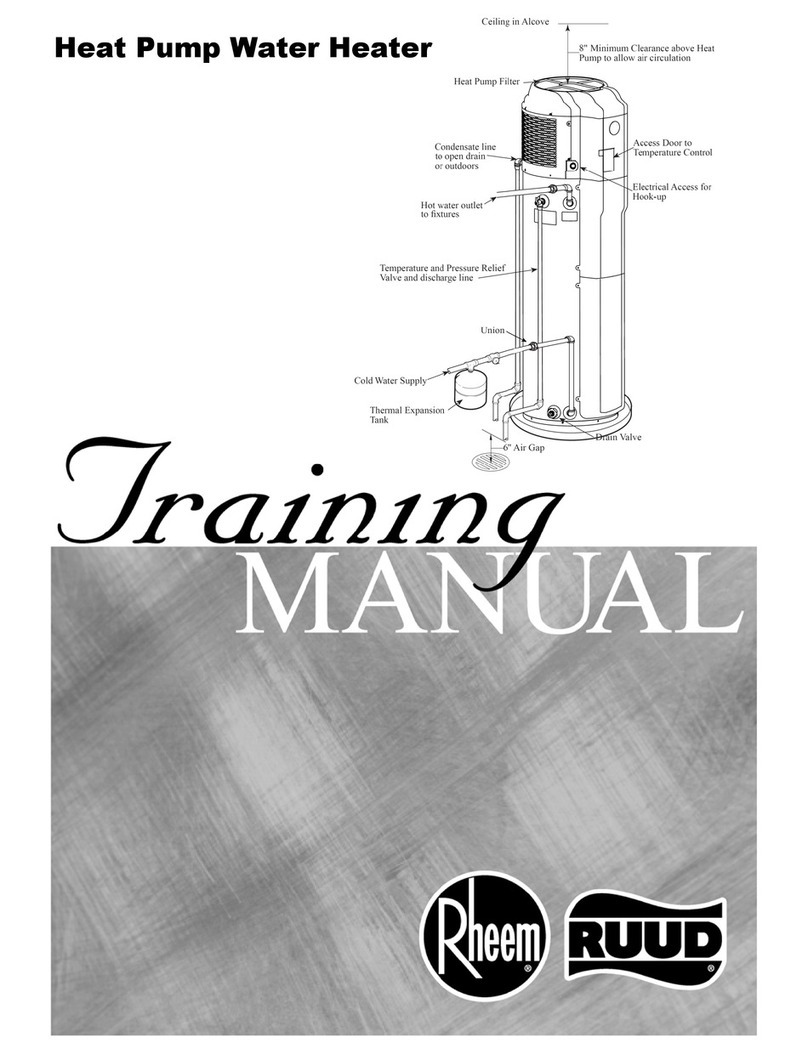

Rheem RUUD Iraining User manual

Rheem

Rheem Solar Premier Loline User manual

Rheem

Rheem RCBH-L199i Guide

Rheem

Rheem Gas Domestic Indoor Water Heater Instruction Manual

Rheem

Rheem 199,000 Btu/hr User manual

Rheem

Rheem Air Sourced 270 Ambiheat Sidevent Technical Document

Rheem

Rheem Pronto 012 Technical Document

Rheem

Rheem Residential Solar Water Heater with Heat... User manual

Popular Water Heater manuals by other brands

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions

Koryo

Koryo KWHZF15Y user manual

Pentair

Pentair PSC-14-4-02 Installation and operation manual

GE

GE 40M06AAG Energy guide