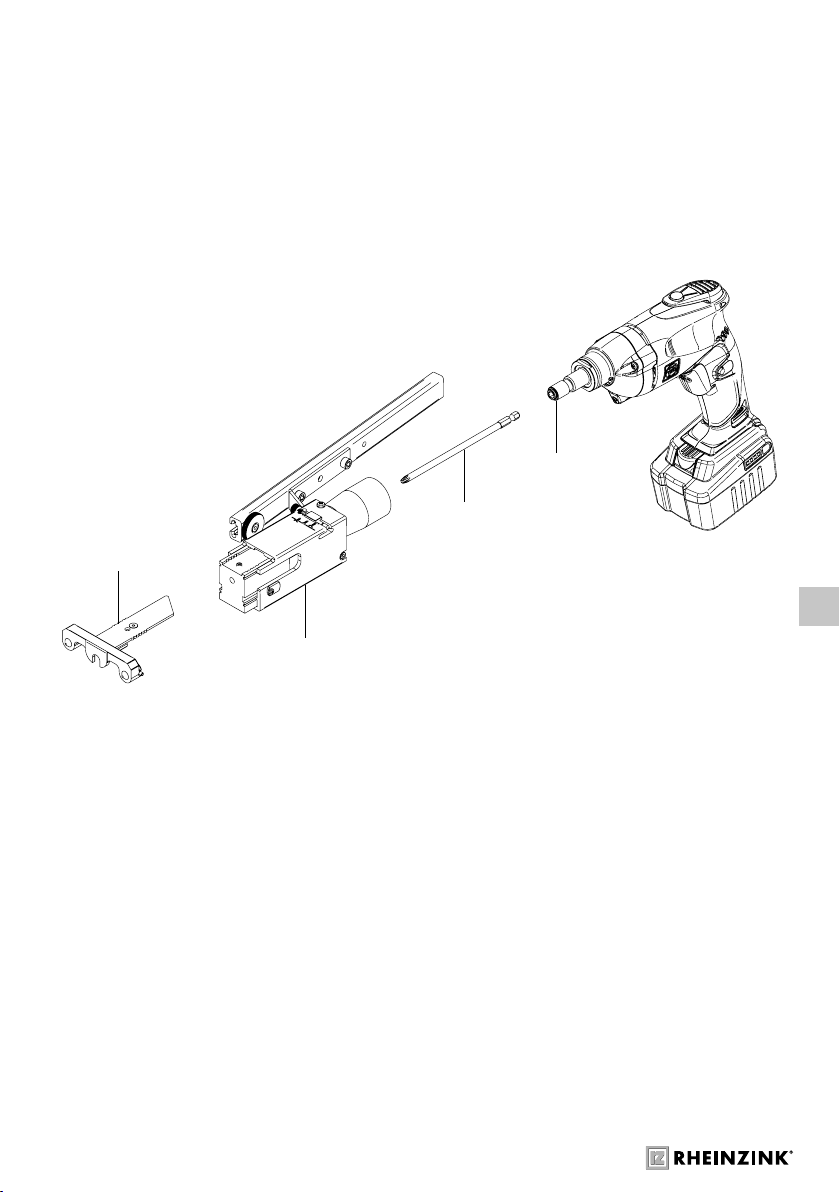

RHEINZINK-CLIPFIX

GB

INSTALLATION WITH CLIPFIX

2. Installation with CLIPFIX

2.1 Static

There are many factors influencing a secure

and durable installation of RHEINZINK

standing seam roofs. Apart from choosing

the most suitable substructure the choice of

the single components of the roofing system

is most important. All measures and functions

of the different parts should fit perfectly.

The RHEINZINK-clips are made of stainless

steel, the CLIPFIX MAGAZIN ATTACHMENT

and the CLIPFIX-Single and Collated Screws

meet highest safety demands.

In wind tunnel studies we tested our RHEIN-

ZINK-Standing Seam System simulating a

wind load over 50 years in combination

with these system elements. At the same time

we simulated a 20-year period in which the

movement of the sliding clips and their be-

havior was examined. The result marks the

beginning of a new era in the installation of

standing seam roofs. The permissible design

load of 600 Newton considerably exceeds

that load of traditional clips. You will work

more economically as processing (screwing

instead of nailing) requires less time due to

greater distances between the clips.

We offer a standard clip with a suitable

height for the installation of RHEINZINK-

Standing Seam Panels either on a (natural)

roof boarding or on suitable wood-based

panels like plywood or oriented strand

boards (OSB). If building physics make the

installation of the structured underlay AIR-Z

or VAPOZINC inevitable, a higher clip is

available. While the standard clips are la-

beled with ST, the higher clips are marked

with H.

You should consult an architect/planner or

a structural engineer for calculating the wind

loads for your construction project. These data

make it easy to determine the number of clips

needed per square metre. Please make use

of our declaration of conformity for your pro-

ject for documenting the wind loads and the

number of installed fixing clips.

It is available for free download on our homepage

www.rheinzink.de / www.rheinzink.com

Information: Assembly of Snow Guard

Systems and Clamps

Snow guard clamps, as well as the RHEIN-

ZINK-Clamp S5 should be mounted in a dis-

tance of at least 25 mm to the next clip to

ensure that the sliding function and the ex-

pansion behaviour of the RHEINZINK roof-

ing still works.