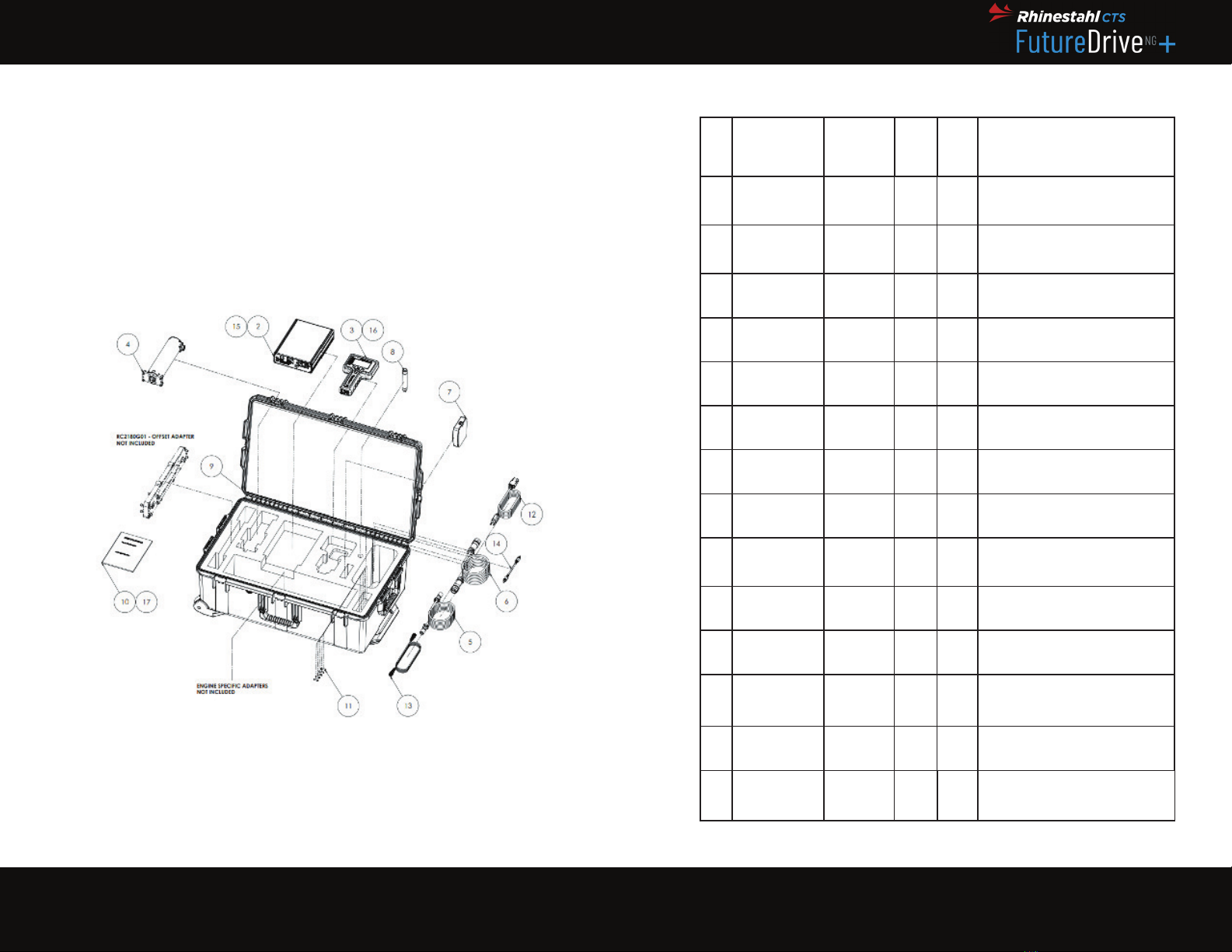

17 18

FutureDriveNG™+ User’s Manual | Wireless Model RC3000G01

RHINESTAHL PROPRIETARY INFORMATION — subject to the restrictions on the cover

7687 Innovation Way, Mason OH 45040 USA | Main +1 513 229 5300 | Fax +1 513 229 3165 | rhinestahl.com

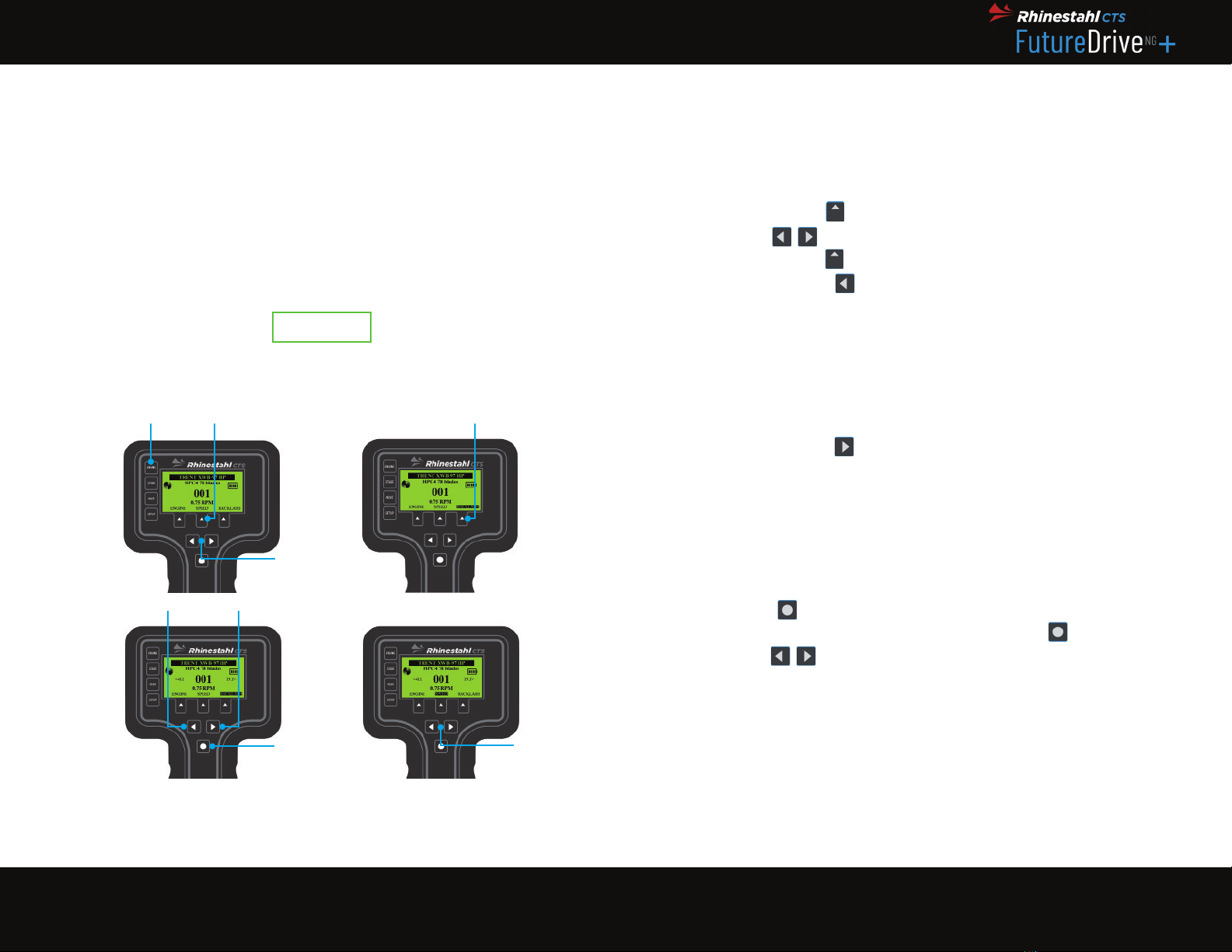

How to select the engine stage to inspect:

The FutureDrive will come pre-programmed for the applicable engine. The unit

knows all the engine’s stages, blade counts, the torque required to turn the

engine, and other information. When the unit is powered on, it will remember

the selected stage from the previous time the unit was used.

STAGE

Note: If backlash is set, changing rotational direction during all move modes will trigger a fl ashing

backlash message. The message with appear on the screen while system compensates for looseness

in the gearbox and will disappear once this action is complete. During backlash compensation time

interval, all hand control buttons will be disabled until this operation is complete, then hand control

button functionality is automatically restored.

Indicates the currently

selected stage and the

number of blades in that stage

Anytime you need

to return to this

screen and change

stages, press the

STAGE button

Use to

cycle through

engine’s stages

Figure 8: Stage Screen

NOTE

How to move the blade in the borescope view:

The jog function allows for positioning of the blades per user preference in how

they’re viewed via borescope. SET VIEW POS will lock this position in, and the

FutureDrive will always stop at this same position for each blade viewed in this

stage. Use JOG and SET VIEW POS for each stage.

When using SET VIEW POS, the current blade will become blade 1 for this

stage.

JOG

Note: If backlash is set, changing rotational direction during all move modes will trigger a fl ashing

backlash message. The message with appear on the screen while system compensates for looseness

in the gearbox and will disappear once this action is complete. During backlash compensation time

interval, all hand control buttons will be disabled until this operation is complete, then hand control

button functionality is automatically restored.

Figure 9: Jog Screen

Use to move the

current blade until it is

positioned the way you

want to view it in the

borescope. Jog can also

be used anytime you want

to turn the engine by an

arbitrary amount, rather

than blade-by-blade.

When you are happy with the view

in the borescope, press under

SET VIEW POS to lock it in. This

FutureDrive will now stop at this

view position on all other blades.

Press and release to

cycle through the various

modes: Jog, Blade, Interval,

and Flag Blade Retrieval

Anytime you need to

return to this screen,

use the MOVE button

When you are happy with the view

in the borescope, press under

NOTE