2

>For any tool used in conjunction with this product,

always read, understand and follow the instructions

and safety warnings for that tool.

>Before using this product, review and verify that all

tools to be used with it have safety equipment

installed and are in proper working order as

definedbythetools’owner’smanuals.

>Do not use this product until you have read and

are confident you understand the:

• Product Specific Safety Warnings (below);

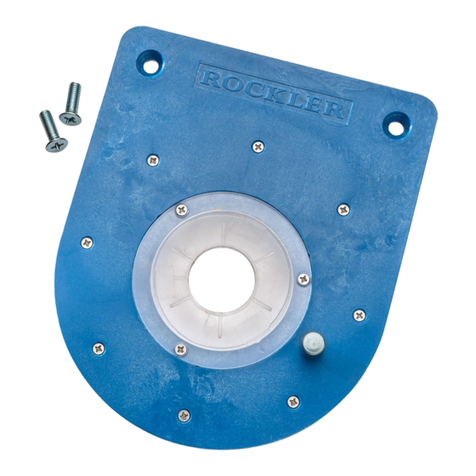

• Connecting the Vacuum Clamp Pods;

• Securing Vacuum Pods to T-Track;

• Securing Vacuum Pods to Another Surface;

• Using the Vacuum Clamp Pods;

• Troubleshooting.

>Remain alert and use good judgment when using

this tool. Do not use this tool if you are in any way

impaired by medications, alcohol, drugs or fatigue.

>Dress appropriately and remove all jewelry, secure

loose clothing and tie up long hair before using

this tool.

>It is the sole responsibility of the purchaser of this tool

to ensure that any third party reads and complies with

all the instructions and safety precautions outlined in

this manual prior to using the tool.

>Maintain these instructions and warnings as long as

you own the tool. Keep this booklet in a place where

it will be readily available for reference.

>The user assumes all risk for the proper use of

this tool and for ensuring product suitability for

intended application.

>Always wear safety glasses in compliance with ANSI

safety standards and hearing protection and follow all

standard shop safety practices including:

•Keep your work area well lit and clean;

•Use dust collection tools and dust face masks to

reduce exposure to dust;

•Use accessory safety equipment such as

feather boards, push sticks and push blocks

whenever appropriate;

•Do not use power tools in explosive

environments (e.g., in the presence of flammable

liquids, fumes or dust);

•Keep children and bystanders away while operating

your tools;

•Maintain proper footing at all times and do

not overreach;

•Do not force the tool;

•Unplug all power tools before making any

adjustments or changing accessories.

>These warnings and instructions do not represent the

total of all information available regarding tool safety,

use and technique. Always seek out opportunities to

learn more and improve your skills and knowledge.

Drilling, sawing, sanding or machining wood

products can expose you to wood dust, a substance known ot

the State of California to cause cancer. Avoid inhaling wood dust

or use a dust mask or other safeguards for personal protection.

For more information go to www.P65Warnings.ca.gov/wood.

This tool is designed for specific applications as defined in the instructions and should not be modified and/or used

for any other applications. Before using the Vacuum Clamp Pods, read, understand and follow all instructions and

safety information provided. KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

GENERAL SAFETY WARNINGS

>Vacuum Clamp Pods are recommended for use

only when attached to a horizontal surface. Use on

a vertical surface increases risk of dangerous

workpiece release.

>Always test the strength of the suction hold before

machining the workpiece. A weak hold could allow

the workpiece to release, potentially causing

serious injury.

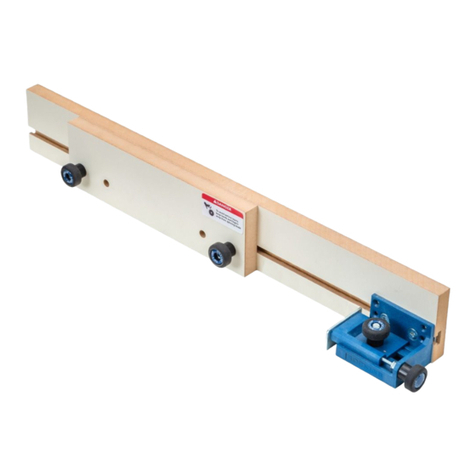

>The Vacuum Clamp Pods must be attached securely

to a work surface and connected to each other and to

the vacuum pump.

>The Vacuum Clamp Pods are not for use while

making through cuts on the workpiece.

>Use the appropriate number of pods to hold and

support your workpiece.

>Avoid large overhangs to reduce risk of workpiece

tilting and breaking the vacuum seal.

>Make sure both the surface of the workpiece and the

gasket and ball valve of the Vacuum Clamp Pods

are clean and free of debris. Any buildup could

interfere with the strength of the seal and the

pods’holdingpower.

>Vacuum hold will be stronger on tighter-grained woods

and less-porous materials.

>Do not expose body parts to the vacuum pressure.

PRODUCT SPECIFIC SAFETY WARNINGS