Page | 5

Description of the four modes of Operation and Slave ID settings

Before we describe the configuration settings and connection diagram of the drive with the motor, we would like to

describe the four modes in which the BLDC motor can run and slave ID addressing which are unique features of the

drive.

Different Modes of Operation: The drive can be configured in the following four modes by the user –

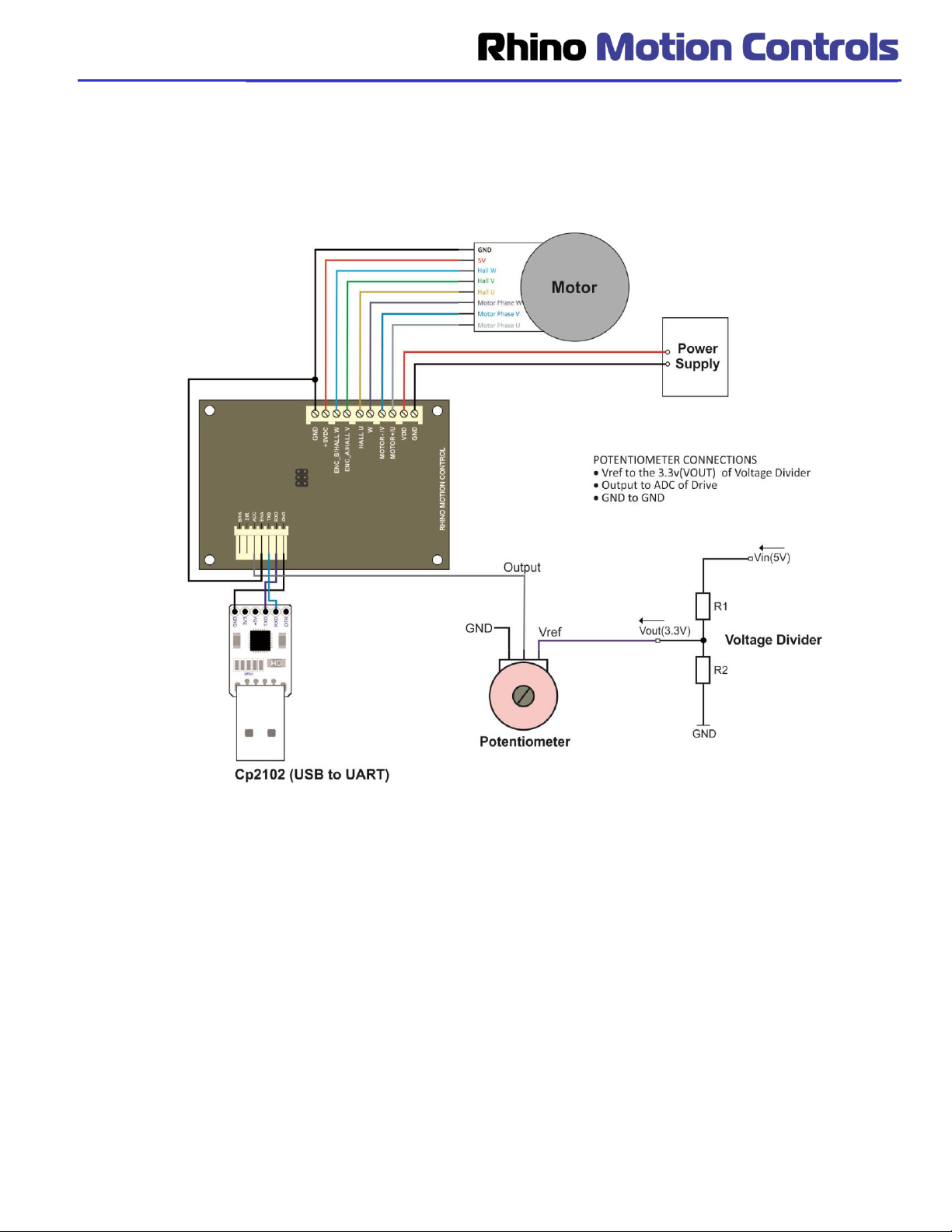

Note: Modes 0 and 3 are Analog Input modes in which a 3.3 V driven potentiometer has to be interfaced with the

‘ADC’ pin of the drive externally

1. Mode 0 Analog input controlled Open Loop PWM mode:

a. In this mode the speed of the Rhino BLDC motor can be controlled by an externally connected

Potentiometer.

b. User can increase or decrease the speed manually based on requirement.

c. The drive will provide full torque at all speeds within the range.

d. However the potentiometer has to be connected via a voltage divider to provide a maximum of 3.3

volts so as to not damage the drive.

e. Also the Enable, Brake has to be connected as per configuration requirements.

f. Direction can not be changed in this mode.

2. Mode 1 Modbus UART ASCII Digitally Controlled Closed Loop Speed Mode:

a. In this mode the frequency and direction of the Rhino BLDC motor is settable / controllable via a

Computer / Arduino Controller board / any other Modbus ASCII compatible device.

b. This mode is used when multiple motors are to be used to run at exactly the same Frequency.

3. Mode 2 Digitally Controlled Open Loop PWM Mode:

a. This mode is used when multiple motors are to be used to run at exactly the same or different

PWM as per the applications.

b. In this mode the direction of the motor can be controlled digitally via Modbus ASCII commands to

run the BLDC motor in both directions

4. Mode 3: Analog Input Closed Loop Mode:

a. In this mode the speed of the Rhino BLDC motor can be controlled by an externally connected

Potentiometer.

b. User can set the minimum speed of the motor and increase or decrease the speed manually

based on requirement.

c. The drive will provide full torque at all speeds within the range.

d. However the potentiometer has to be connected via a voltage divider to provide a maximum of 3.3

volts so as to not damage the drive.

e. Also the Enable, Brake has to be connected as per configuration requirements.

f. Direction cannot be changed in this mode.