Introduction 1

About This Manual

This manual is intended for use by service technicians

responsible for installing and servicing 320IS Plus

digital weight indicators. This manual applies to

indicators using Version 2.0 of the 320IS Plus

software.

Configuration and calibration of the indicator can be

accomplished using the indicator front panel keys, the

EDP command set, or the 320IS Plus configuration

utility. See Section 3.1 on page 13 for information

about configuration methods.

Some procedures described in this

manual require work inside the

indicator enclosure. These procedures

are to be performed by qualified

service personnel only.

Improper specification, installation, or service of this

equipment could result in personal injury or property

damage.

The 320IS Plus is a Factory Mutual-Entity approved

component. This approval is valid only if the installation

conforms to the guidelines described in this manual and

FM-approved control drawing (PN 72717). If

modifications are made to the installation procedure, or

the instrumentation is changed in any way, Factory

Mutual approval is void and the customer becomes fully

responsible for such modifications.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor

site at www.ricelake.com.

1.0 Introduction

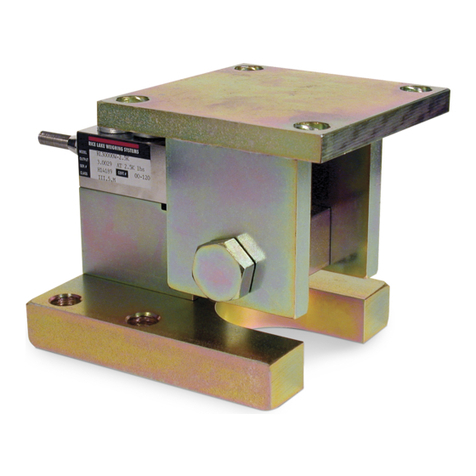

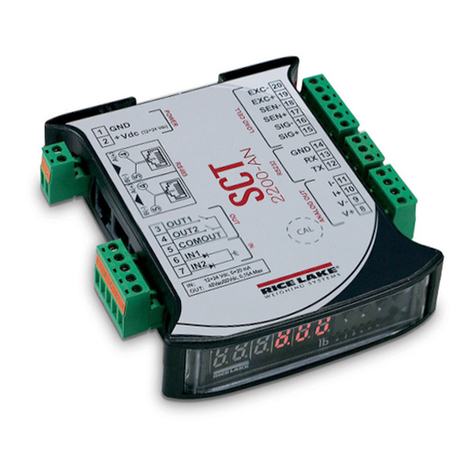

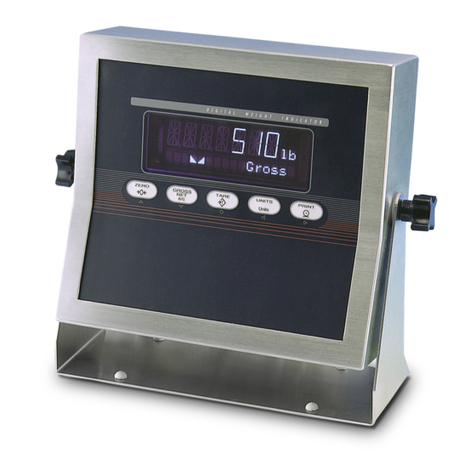

The 320IS Plus is a single-channel digital weight

indicator designed and approved to operate as an

intrinsically safe system in a wide variety of scale and

weighing applications. The indicator is housed in a

NEMA 4X/IP66-rated stainless steel sealed case. The

standard unit is equipped with a tilt stand base for

tabletop or wall mounting applications. The indicator

front panel consists of a large (0.8 in, 20 mm,

16-segment), six-digit LED display, 24-button keypad

and eight LED annunciators. Features include:

• Drives up to four 350Ω or eight 700Ωload

cells

• Supports four- and six-wire load cell

connections (six-wire remote sense

recommended)

• Full-duplex fiber optic interface to attach an

external I/O board located in the safe area

The 320IS Plus is NTEP-certified and pending

Measurement Canada approval for Classes I, II and III

at 10,000 divisions. See See Section 9.10 on page 68

for detailed specifications.

Available with optional I/O Module (PN 72721):

• Four configurable digital inputs

• Four digitally-controlled single pole single

throw-normally open non-latching relay

contact outputs

• Electronic data processing (EDP) port

communications at up to 38400 bps for full

duplex RS-232/RS-422/RS-485 and Current

loop

• Printer port communications at up to 38400

bps for full duplex RS-232/RS-422/RS-485

and Current loop

• Two 16–bit analog output channels provide

±10V or ±5V, 0-5V or 0-10V, and 4-20 mA

tracking of gross or net weight values

1.1 Factory Mutual Approval

The 320IS Plus is Factory Mutual (FM) Entity

approved for:

• Classes I, II, and III

• Divisions 1 and 2

• Groups A, B, C, D, E, F and G

• T-rating T4

Only devices that have FM Entity Approval with

proper entity parameters may be used unless

specifically listed in this manual or control drawing

PN 72717 as part of the Rice Lake Factory Mutual

systems approval. Failure to comply with this voids

the FM approval.

The classification of hazardous materials are different

in the US and European standards. Because of this, the

safety class of the 320IS Plus is declared in the

following regulations:

• US standards: Class I, II, III, DIV1, Groups

A-G

Substitution of components may impair

intrinsic safety.

To prevent ignition of flammable or

combustible atmospheres, disconnect

power before servicing.

Warning

Warning