Installation Guide

Contents Page

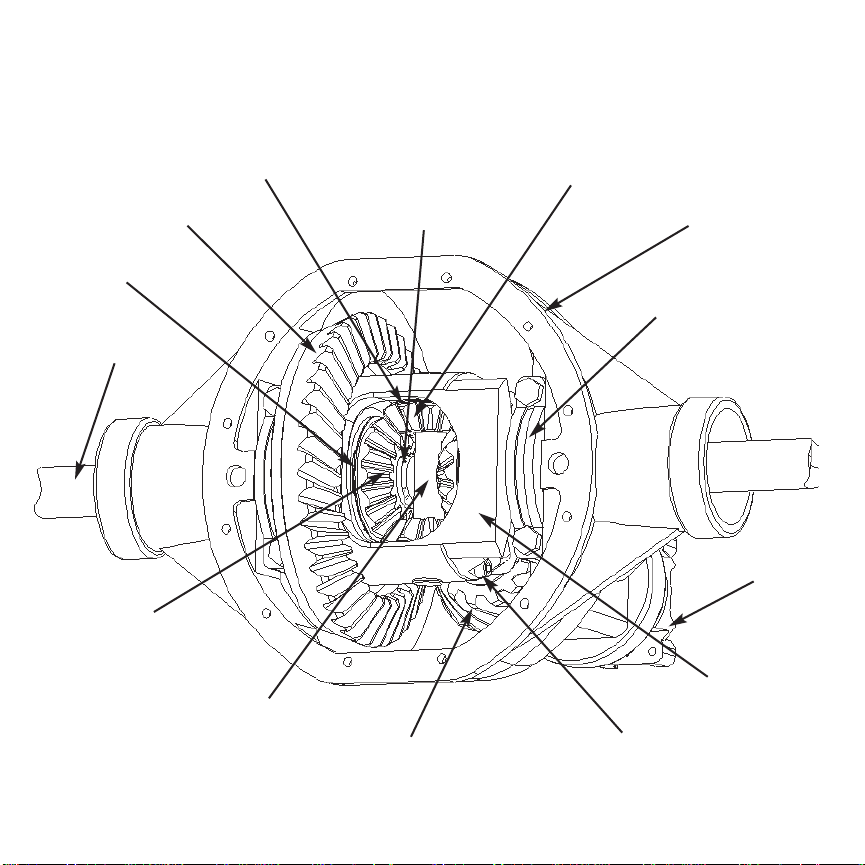

Open Differential Part Identification & Terminology ......... 2

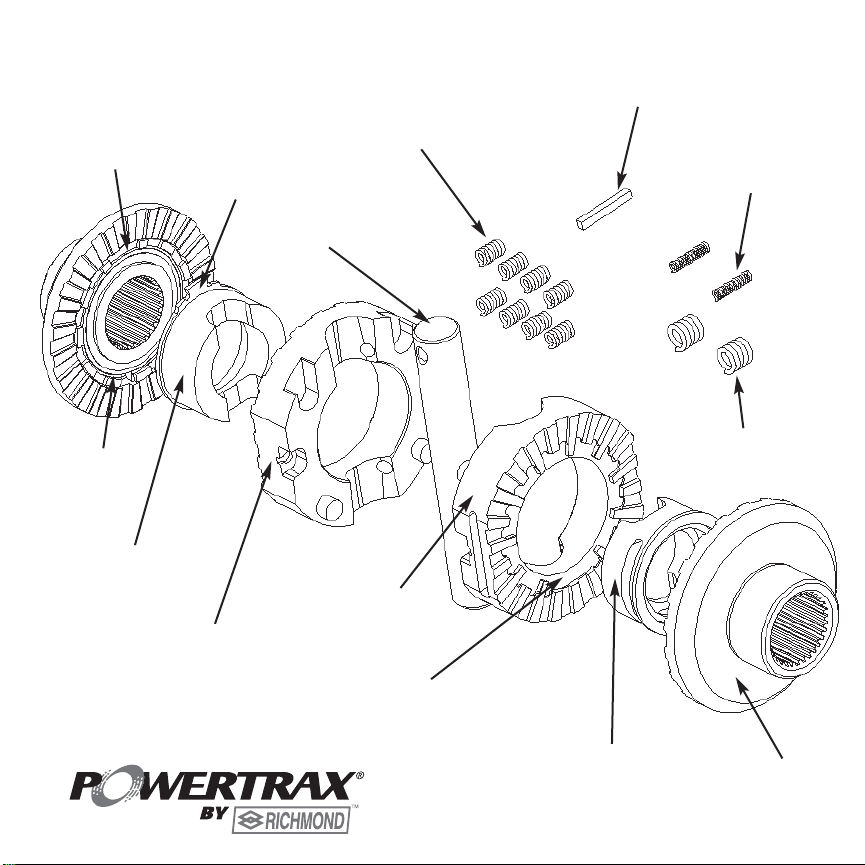

Powertrax No-Slip Differential Exploded View .................. 3

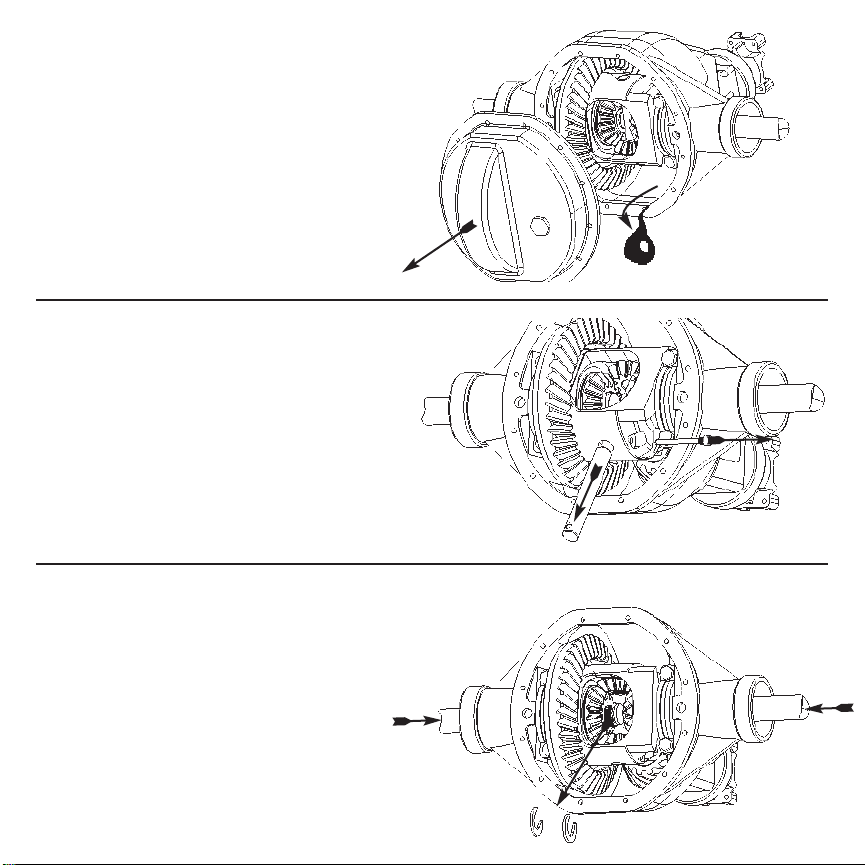

Vehicle Preparation for Installation (steps 1 to 5) ............. 4

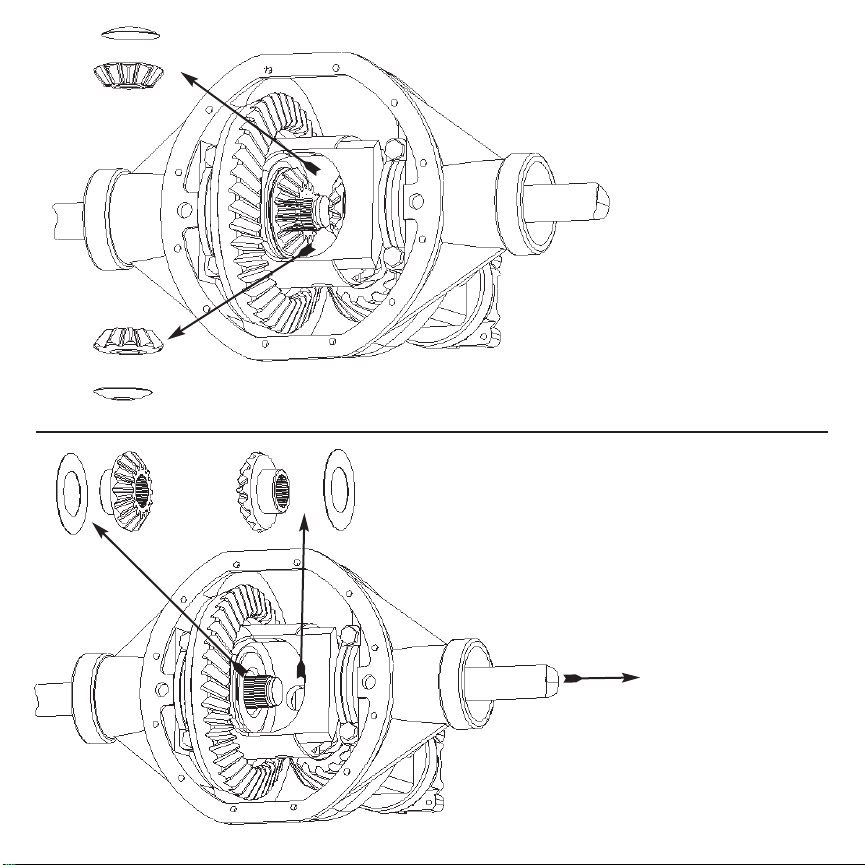

Removal of Open Differential Parts (steps 6 to 10) ........... 5

Preparation of Parts to be Installed (steps 11 to 13) ......... 7

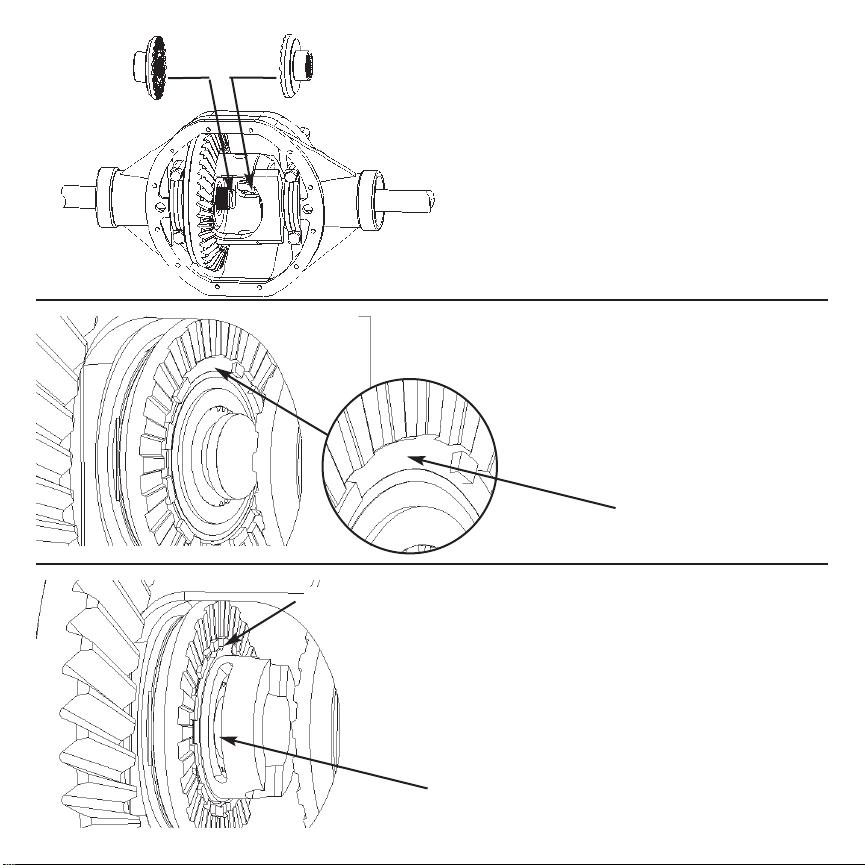

Assembly (steps 14 to 40) .............................................. 8

Verification of Proper Assembly Test (steps 41 to 45) ....... 17

Finish Installation (steps 46 to 50) .................................. 18

Thoroughly read User Manual.

Traction output and resulting handling characteristics of your vehicle will be modified by installation.

Drive carefully and use caution under all on-road and off-road conditions.