3

Before First Operation

• Purchaser/ownermustensurethat

productisinstalledaccordingto

theseinstructions.Purchaser/own-

ermustnotalterormodifyproduct.

• Understandyourwinchand

itsinstructions.

• Neverexceedmaximumrated

capacity.Refertostamped

markingsordecalsonproductto

obtainratedcapacity.

• Thewinchisratedatthefirstlayer

ofwireropeonthedrumforinter-

mittent-periodicduty.

Are you ready to pull?

• NEVERoperatethiswinchwhen

undertheinuenceofdrugs,alco-

holormedication.

• ALWAYSremovejewelry

andweareyeprotection.

• Useleatherglovesorahand

savercablestrapwhenhandling

thewirerope.

• NEVERletwinchropeslipthrough

yourhands.

• Nevertouchawinchropeorhook

whensomeoneelseisatthe

controls.

• NEVERtouchwinchropeorhook

whileundertensionorunderload.

• ALWAYSstandclearofwinchrope

andloadandkeepothersaway

whilewinching.

• Donotusethe

winchasaliftingdeviceorahoist

forverticallift.

• Operatorandbystandersshould

neverpositionanypartofbody

underanyportionofthisproductor

theloadbeingsupported.

• Donotallowchildrentoplayon

oraroundthisproductortheload

beingsupported.

• Keep

clearofwinch,rope,hook,and

fairleadwhileoperating.

• Thewinchisnottobe

usedtolift,supportorotherwise

transportpersonnel.

• ALWAYSbeawareof

possiblehotsurfacesatwinch

motor,drumorropeduringorafter

winchuse.

• ALWAYSensuretheoperatorand

bystandersareawareofthestabili-

tyofthevehicleand/orload.

Is your winch ready to pull?

• ALWAYSinspectwinchrope,hook,

andslingsbeforeoperatingwinch.

Frayed,kinkedordamagedwinch

ropemustbereplacedimmediate-

ly.Damagedcomponentsmustbe

replacedbeforeoperation.

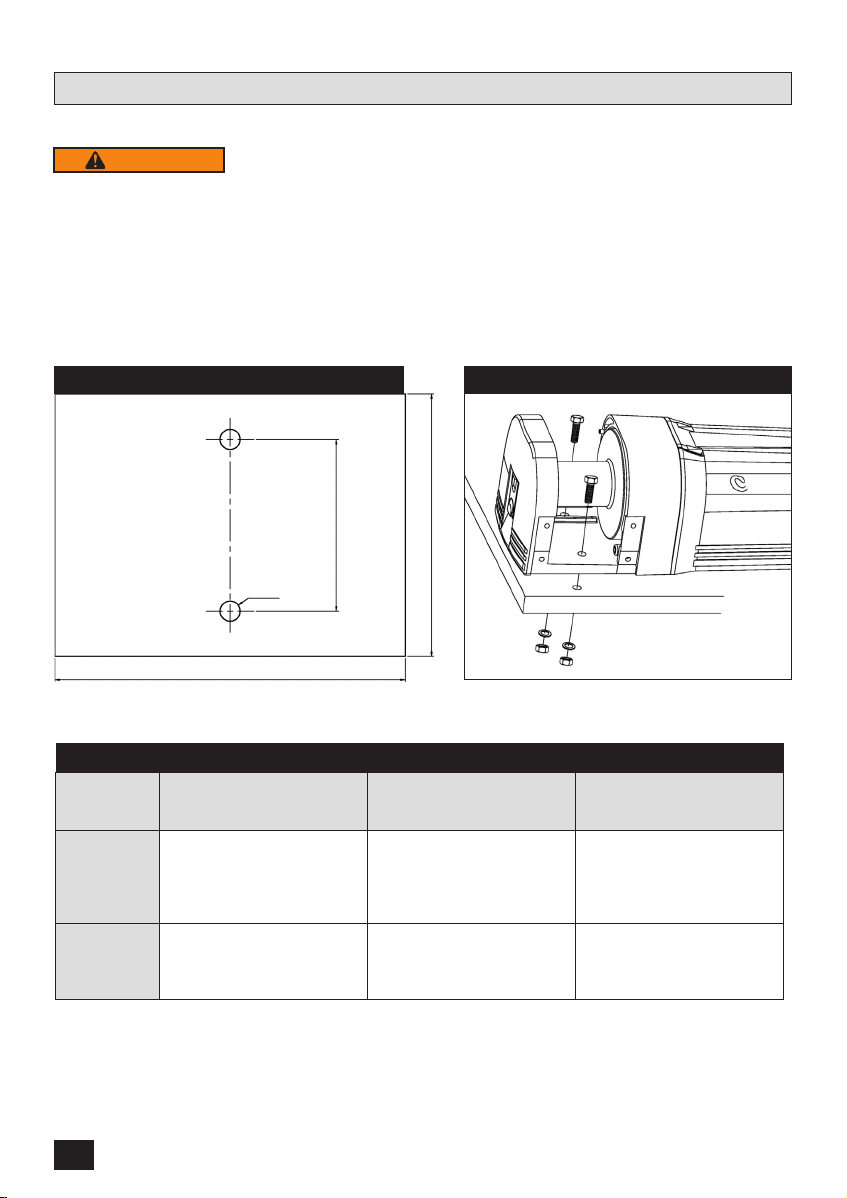

• Periodicallycheckmountinghard-

wareforpropertorqueandtighten

ifnecessary.

• ALWAYSremoveanyelementor

obstaclethatmayinterferewith

safeoperationofthewinch.

• ALWAYSbecertaintheanchoryou

selectwillwithstandtheloadand

thestraporchainwillnotslip.

• Wireropecanbreakwithoutwarn-

ing.Alwayskeepasafedistance

fromthewinchandropewhile

underaload.

• ALWAYSkeepwiredpendant

controlleadandpowercordclear

ofthedrum,rope,andrigging.

Inspectforcracks,pinches,

frayedwiresorlooseconnections.

Damagedcomponentsmustbe

replacedbeforeoperation.

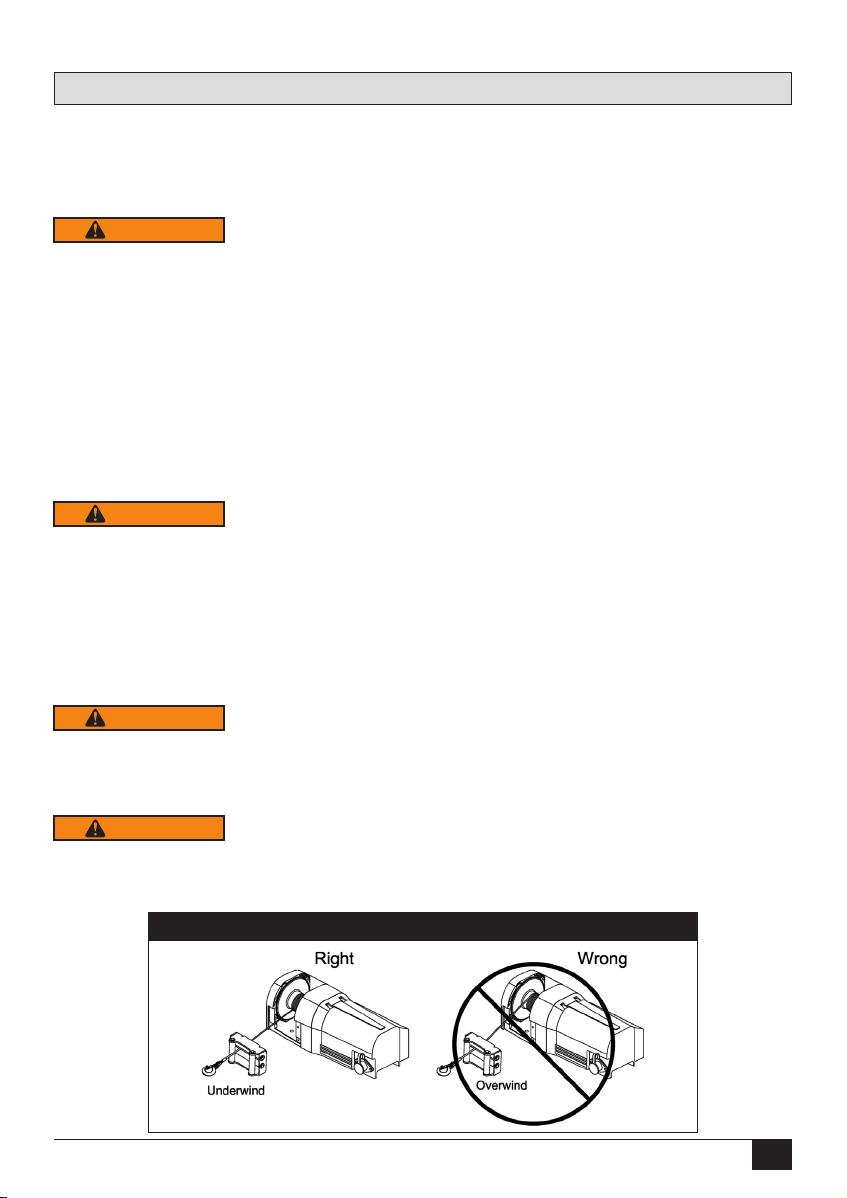

• NEVERwrapwinchrope

backontoitself.Useachoker

chainorstrap.

• ALWAYSensurehooklatch

isclosedandnotsupportingload.

• NEVERapplyloadtohook

tiporlatch.Applyloadonlytothe

centerofhook.

• NEVERuseahookwhosethroat

openinghasincreased,orwhose

tipisbentortwisted.

• ALWAYSuseahookwithalatch.

• Neverusewinchropefortowing.

• NEVERuseexcessiveefforttofree

spoolwinchrope.

• ALWAYStaketimetouseappropri-

ateriggingtechniquesforawinch

pull.

During the pull

• NEVERexceedwinchorwinch

roperatedcapacity.Doubleline

usingasnatchblocktoreduce

winchload.

• Donotshockloadthewinch.

• Neveruseawinchtosecureaload.

• ALWAYSunspoolasmuchwinch

ropeaspossiblewhenrigging.

Doublelineorpickdistantanchor

point.

• Neverengageordisengagethe

clutchwhenthewinchisunder

loadorthedrumismoving.

• Pullfromanangleoflessthan5

degreeslaterallyand15degrees

horizontly.Withoutmaintainingthe

propereetangleof+/-5degrees;

(SeeFigure18page15)therope

willpileontoonesideoftherope

drumandpossiblydodamageto

theropeorwinch.Re-spoolyour

winchasrequired.

• Whenwinchingaheavyload,lay

arecoverydamperoraheavy

blanketoverthemiddlethirdofthe

wirerope.

• ALWAYSavoidsidepullswhich

canpileupwinchropeatoneend

ofthedrum.Thiscandamage

winchropeorwinch.

• ALWAYSensuretheclutchis

fullyengagedordisengaged.

Thetypeofdutyisintermittent-

periodicdutyS3andtheloadtime

neverexceeds2minutes.

• NEVERsubmergewinchinwater.

After Use

• Disconnectthehandheldpendant

fromthewinchwhennotinuse.

• ALWAYSstorethependantcontrol

inaprotected,clean,dryarea.

Important Safety Messages