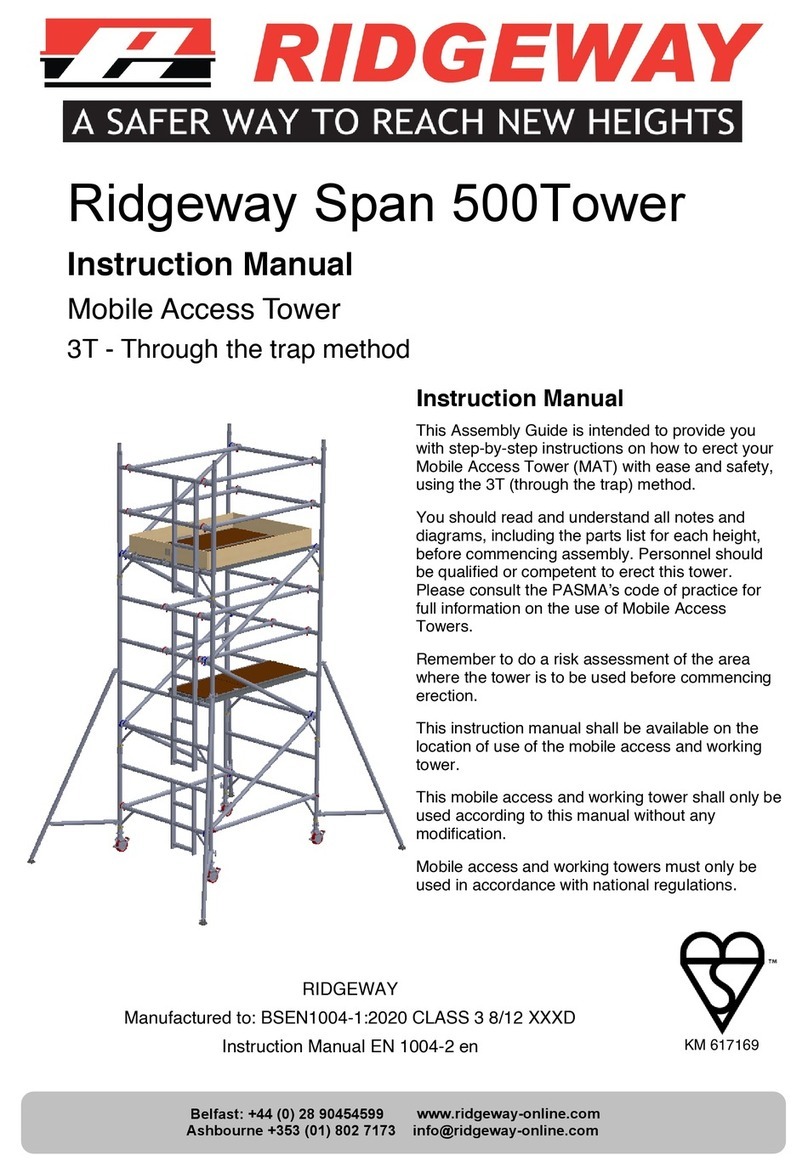

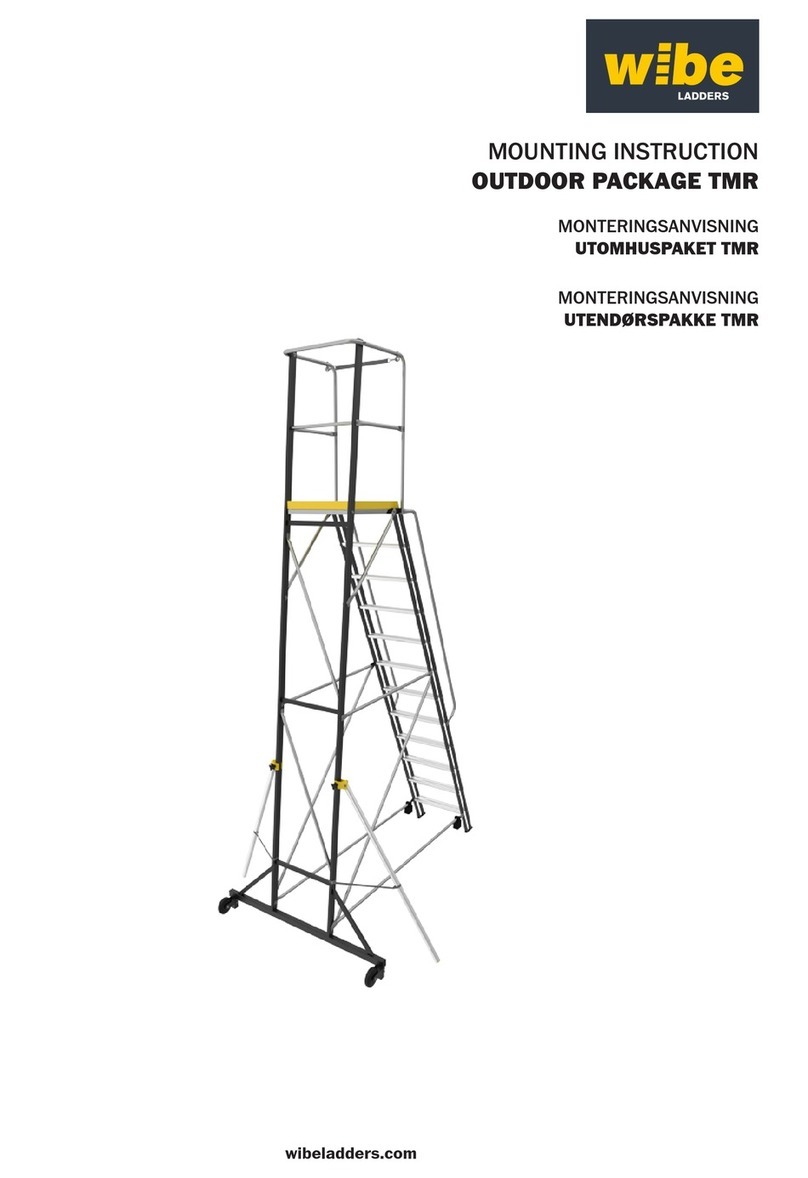

Lightly tighten the upper clamps above the sixth rung on each corner post. Position

the lower clamp above the bottom rung. Ensure the lower arm is as horizontal as

possible. Position the stabilisers so that the footpads are approximately equidistant

from each other, as seen here. Telescopically adjust the leg and reposition the clamps

as required to make firm contact with the ground. Ensure the clips with locking pin

are in place. When in the correct position, tighten the clamps firmly.

To position the tower against a wall, do not remove the stabiliser, move parallel with

the wall.

To position the tower in a corner, remove the inside stabiliser and place the outside

two parallel with the wall.

Ballast weight maybe used to stabilise the tower, please contact your supplier for the

correct amount of ballast weight required.

STABILISERS

USAGE ADVICE

• We recommend a minimum of two people to assemble, dismantle and move the

platform tower.

• Check that all components are on site and in good working order.

• Ensure that assembly location is checked to prevent hazards during assembly,

dismantling or moving and while working on the tower. Particular attention should be

given to the ground condition, whether level or sloping, obstructions and wind

conditions. The ground condition should be capable of supporting the tower structure.

• Towers must always be climbed from the inside of the assembly and using the built-in

ladder if provided.

• Lifting operation should be done inside the effective base area of the tower.

• Moving the tower should only be done by manual effect from the base of the

tower. When moving tower be aware of overhead hazards (eg. electric cables).

• No personnel or material should be on the platform whilst the tower is being moved.

• Beware of horizontal loads which can lead to instability of the tower. The maximum

side force is 20kg.

• Not to be used on sloping surfaces.

• Do not use boxes or steps to gain additional height. If extra height required, contact

your distributor to get extra components.

• Do not lift or suspend assembled mobile tower.

• Components are normally hoisted using a rope. Always lift within the tower structure

or within the base rectangle defined by the stabilisers.

• Damaged components, or components from other tower systems should never be

used.

• Stabilisers should always be fitted when specified. Use the type of stabiliser shown

on the component list according to the tower height.

• When wind exceeds Beaufort force 4, cease using the tower. Wind speeds:

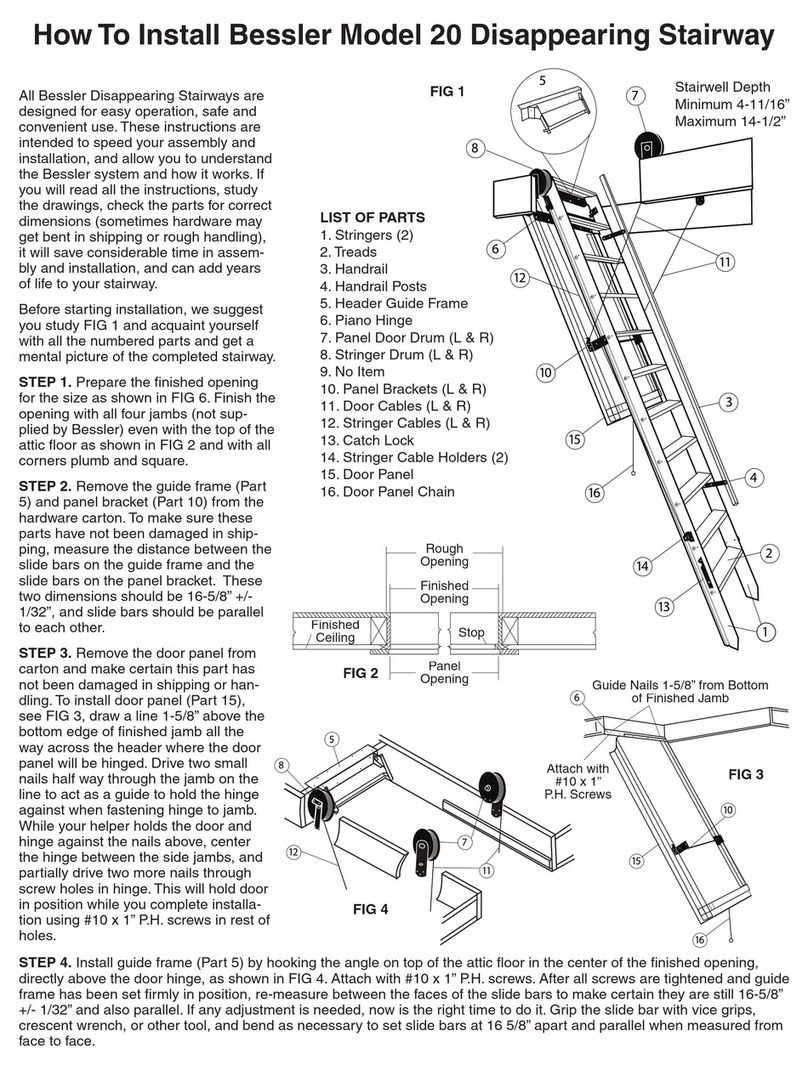

Snappy 300

Platform Height 1m 2m 3m 4m

Basic Snappy kit 1 1 1 1

Horizontal Brace 3 1 1 5

Diagonal Brace 2 2

Platform 1 1 2 2

Extension Frame 2 2

Guardrail Frame 2 2

Bracing Frame 2 2 2

Toeboard Set 1* 1 1

* Toeboard set at 2m based on risk assessment

CARE AND MAINTENANCE OF THE TOWER AND COMPONENTS

• Keep all equipment clean, especially spigots and sockets where frames join. Spigots

should fit easily into stocks. Lubricate with light oil.

• Do not strike or hammer components. Do not throw or drop onto hard surfaces.

• Lightly oil spring mechanism of the hooks.

• For transport and storage, components are best stored vertically.

• Damaged parts should be repaired or replaced, contact your supplier.

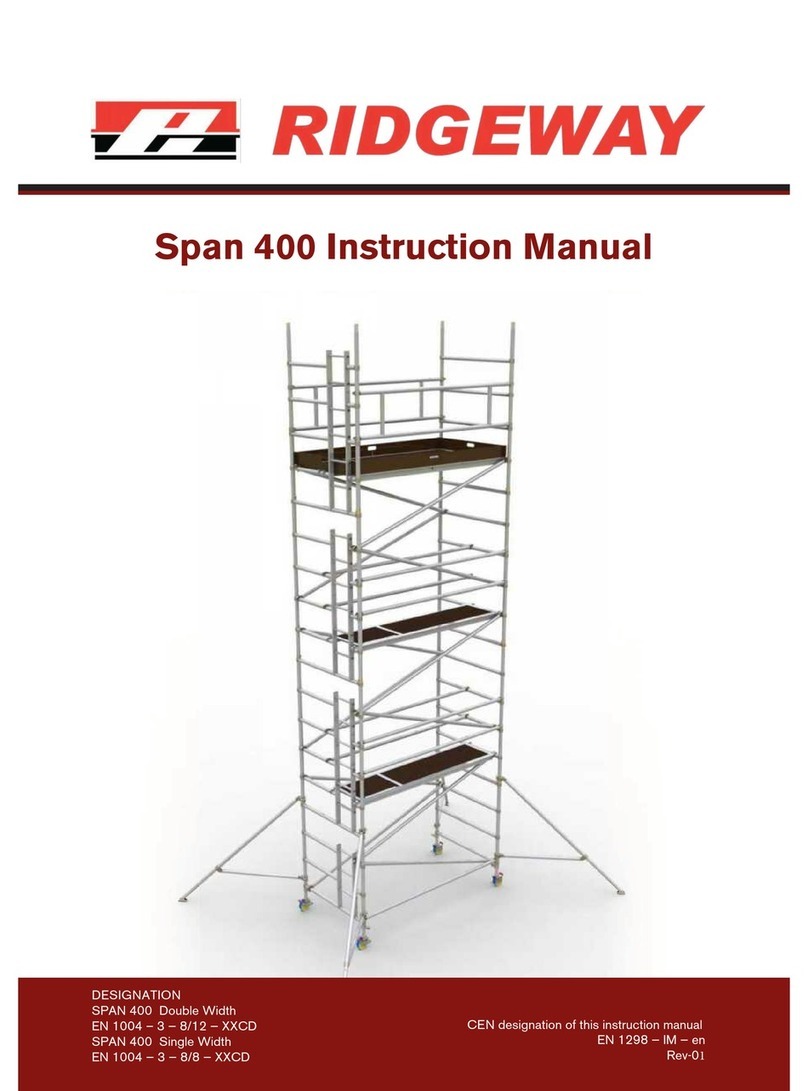

TOWER COMPONENTS REQUIRED

The following tables show a full list of components to build the tower to the platform

height specified, complying with the requirements of EN 1004 and Work at Heights

Regulations (WAHR). Total self-weight of towers are indicated.

ALTERNATIVE PLATFORM HEIGHTS

Platforms can be installed in any

rung position up to the 10th rung.

Use bracing frames on either side

to provide adequate fall

protection and toeboards based

on risk assessment.

Force Peak Mph Peak Kph Guidance

4 18 29 Moderate breeze - raises dust & loose paper

6 31 50 Strong breeze - difficult to use umbrella

8 46 74 Gale force - walking is difficult

To Dismantle, follow the build process but in reverse order noting the

following.

• To remove the guardrail frames or braces, first unlock the hook

at the end away from the trapdoor.

• Sitting through the trapdoor, unlock the near end hook and

remove the brace.

To Move the tower to a new position, first prepare the tower.

• Wind speed should not exceed 29 km /hr (force 4).

• Release the castor brakes.

• Raise the stabiliser feet only enough to clear obstructions.

• Ensure tower is empty (material and personnel). Move the

tower manually by applying force at the base - do not use

machinery to push or pull the tower. Once moved - prepare

the tower for use.

• Check all castors and stabilisers are in firm contact with the

ground.

• Reapply the castor brakes.

DISMANTLING / MOVING TOWERS

Email:

Web: www.ridgway-online.comridgeway-online.com@info

Belfast:

Belfast

Co.

BT3

Tel: 9045459982(0)44+

9EDDown WestRoadAirport103 Ashbourne:

Unit

Ratoath

Ashbourne

Co.

48A

Tel:

3717028(01)+353

8D9X

MeathRoad ParkGreene2&1