English - 3Ridge Tool Company

TM

Equipment Use and Care

yDo not force equipment. Use the correct equipment for

your application. The correct equipment will do the job

better and safer at the rate for which it is designed.

yDo not use equipment if the power switch does not

turn it ON and OFF. Any equipment that cannot be

controlled with the power switch is dangerous and must

be repaired.

yDisconnect the plug from the power source and/or

the battery pack from the equipment before making

adjustments, changing accessories, or storing.

Preventive safety measures reduce the risk of injury.

yStore idle equipment out of the reach of children and

do not allow persons unfamiliar with the equipment

or these instructions to operate the equipment.

Equipment can be dangerous in the hands of untrained

users.

yMaintain equipment. Check for misalignment or binding

of moving parts, missing parts, breakage of parts, and

any other condition that may affect the equipment’s

operation. If damaged, have the equipment repaired

before use. Many accidents are caused by poorly

maintained equipment.

yUse the equipment and accessories in accordance

with these instructions; taking into account the

working conditions and the work to be performed.

Use of the equipment for operations different from those

intended could result in a hazardous situation.

yUse only accessories that are recommended by the

manufacturer for your equipment. Accessories that

may be suitable for one piece of equipment may become

hazardous when used with other equipment.

yKeep handles dry, clean, and free from oil and grease.

This allows for better control of the equipment.

Battery Use and Care

WARNING

Read the battery charger manual before using the charger

or batteries. Failure to read, understand and follow the

contents of the charger manual may result in extensive

property damage, severe personal injury, or death.

yRecharge only with the charger specied by the

manufacturer. A charger suitable for one type of battery

pack may create a risk of re when used with another

battery pack.

yUse equipment only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

yDo not probe battery with conductive objects.

Shorting of battery terminals may cause sparks, burns,

or electrical shock. When the battery pack is not in use,

keep it away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects

that can make a connection from one terminal to another.

Shorting the battery terminals together may cause burns

or a re.

yUnder abusive conditions, liquid may eject from

battery; avoid contact. If contact occurs, ush with

water. If liquid contacts eyes, seek medical help. Liquid

ejected from the battery may cause irritation or burns.

yUse and store batteries and chargers in dry,

appropriate temperature areas. Extreme temperatures

and moisture can damage batteries and result in leakage,

electrical shock, re or burns. See charger manual for

more information.

yDo not cover charger while in use. Proper ventilation

is required for correct operation. Covering charger in use

could result in re.

yProperly dispose of batteries. Exposure to high

temperatures can cause the batteries to explode; do not

dispose of in a re. Some countries have regulations

concerning battery disposal. Follow all applicable

regulations.

Service

Ensure a qualied repair person services your equipment

using only identical replacement parts to maintain the

safety of the tool. Remove the batteries and refer servicing

to qualied service personnel under any of the following

conditions:

yIf liquid has been spilled or objects have fallen into product.

yIf the product does not operate normally when following

the operating instructions.

yIf the product has been dropped or damaged.

yWhen the product exhibits a distinct change in

performance.

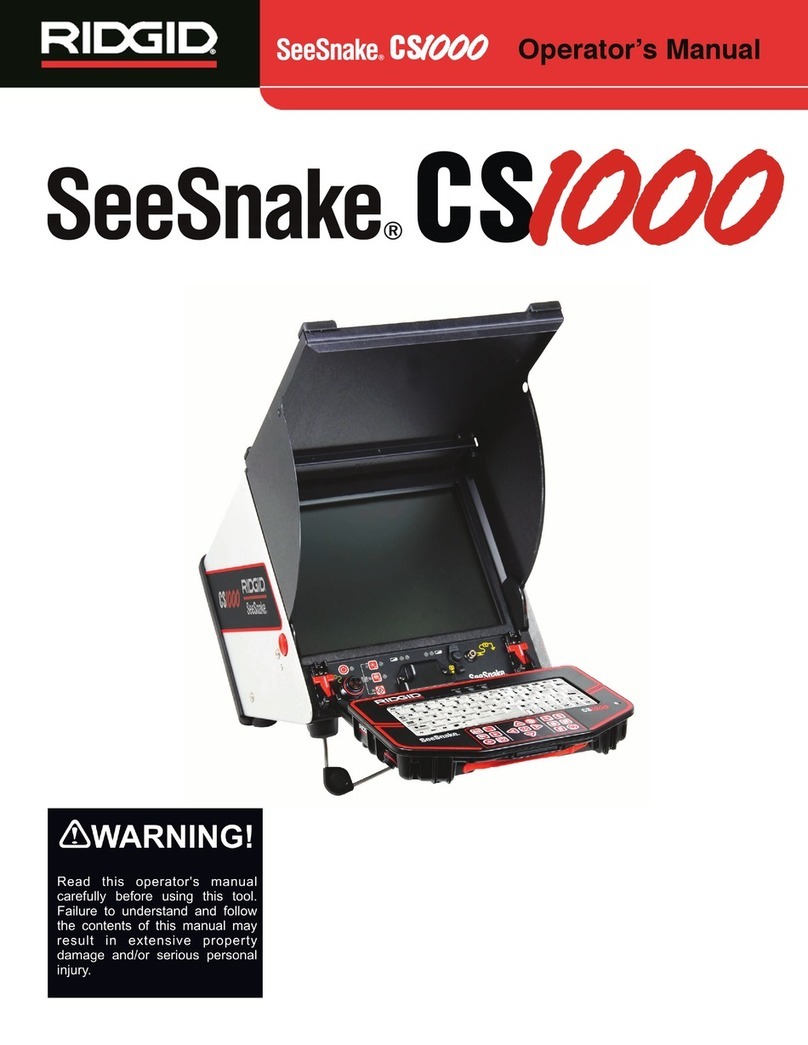

Specic Safety Information

WARNING

This section contains important safety information that is

specic to the CS1000. Read these precautions carefully

before using the CS1000 to reduce the risk of electrical

shock, re, or other serious personal injury.

SAVE THESE INSTRUCTIONS!

Keep this manual with the equipment for use by the operator.

CS1000 Safety

yThe equipment is intended for indoor use when used

with the AC power supply. When powered by battery