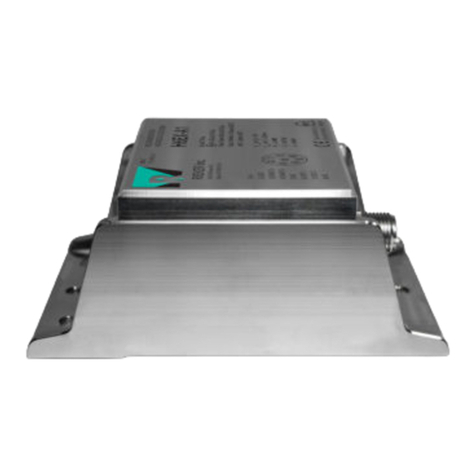

Flex™ H6 User Guide

Page 1 of 29

RIEKER INC • 34 MOUNT PLEASANT ROAD • ASTON • PA • 19014 • USA

The information and material presented may not be published, broadcast, rewritten, or redistributed without the expressed wri

tten consent of Rieker

Inc.

The content presented is provided for informational purposes only and subject to change.

7 Rieker®All Rights Reserved.

FORM NUMBER: H60009_12/14 UPDATED:

5/15/18

Table of Contents

Sensor Description...................................................................................................................................3

Updates & Revision History .....................................................................................................................3

Sensor Specifications...............................................................................................................................4

Sensor Specifications, Continued ............................................................................................................5

H6 Installation and Wiring ........................................................................................................................6

Horizontal Mount Axis Orientations .................................................................................................8

Vertical Mount Axis Orientations .....................................................................................................8

H6 Connector Wiring Tables..............................................................................................................11

H6 RS485 Bus Wiring Configurations ...............................................................................................12

Analog Outputs ......................................................................................................................................14

Output Axis Mapping .........................................................................................................................14

Output Types .....................................................................................................................................14

Current Output...............................................................................................................................14

Voltage Output...............................................................................................................................14

Switch Output ................................................................................................................................14

Sensitivity & Zero Angle Calculation (Voltage and Current Outputs Only)........................................15

Wiring Diagrams and Connection Procedures ..................................................................................16

Wiring for a Current Output ...........................................................................................................16

Wiring for a Voltage Output ...........................................................................................................18

Wiring for a Switch Output.............................................................................................................19

Digital RS485 Communications .............................................................................................................20

RS485 Protocol..................................................................................................................................20

Packet Format ...............................................................................................................................20

RS485 Command Functions..............................................................................................................21

Function Descriptions ....................................................................................................................22

Appendix A. Creating an H6 Development Cable..................................................................................29