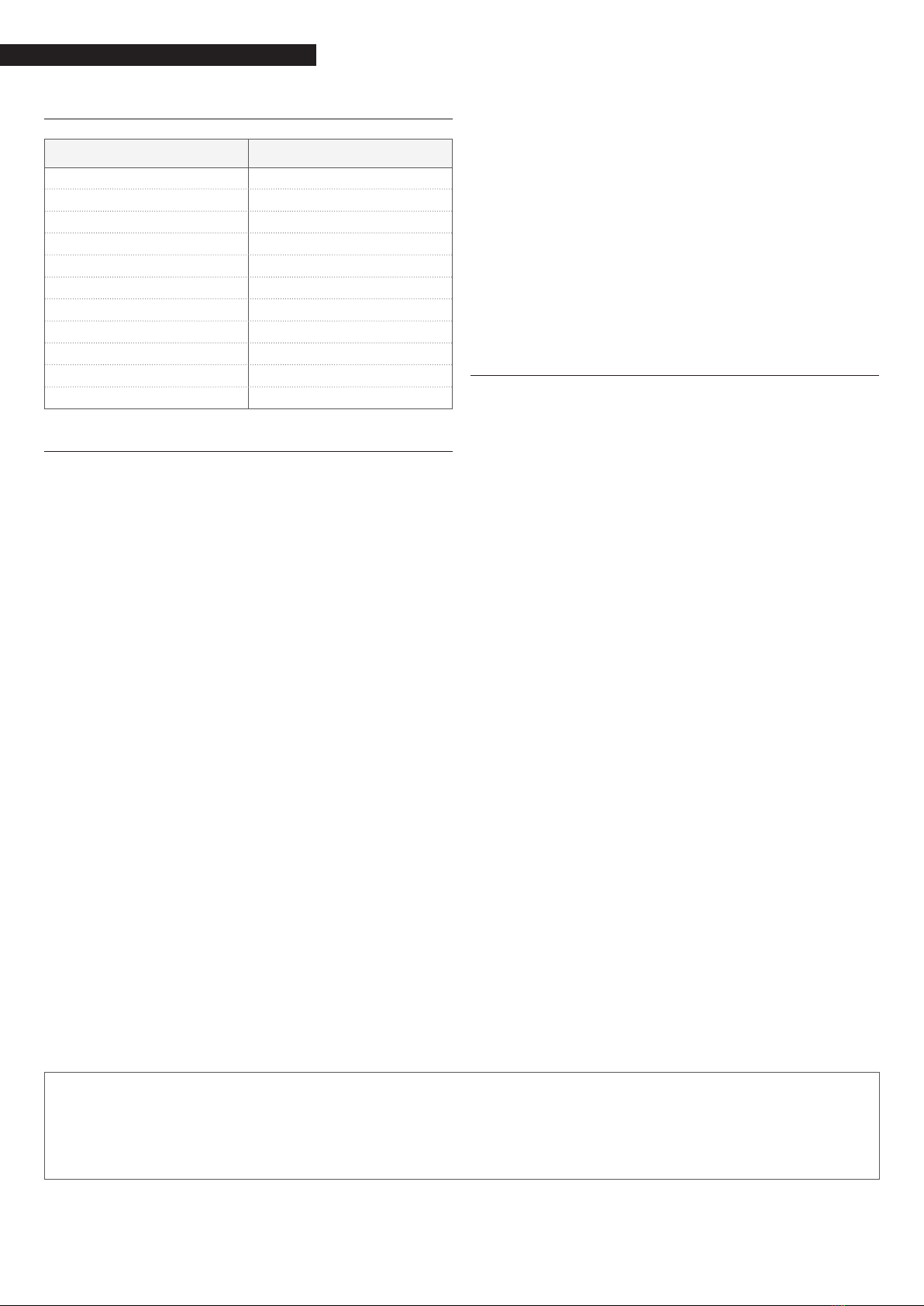

Riello RTT 378 User manual

Other Riello Boiler manuals

Riello

Riello RTT 76 User manual

Riello

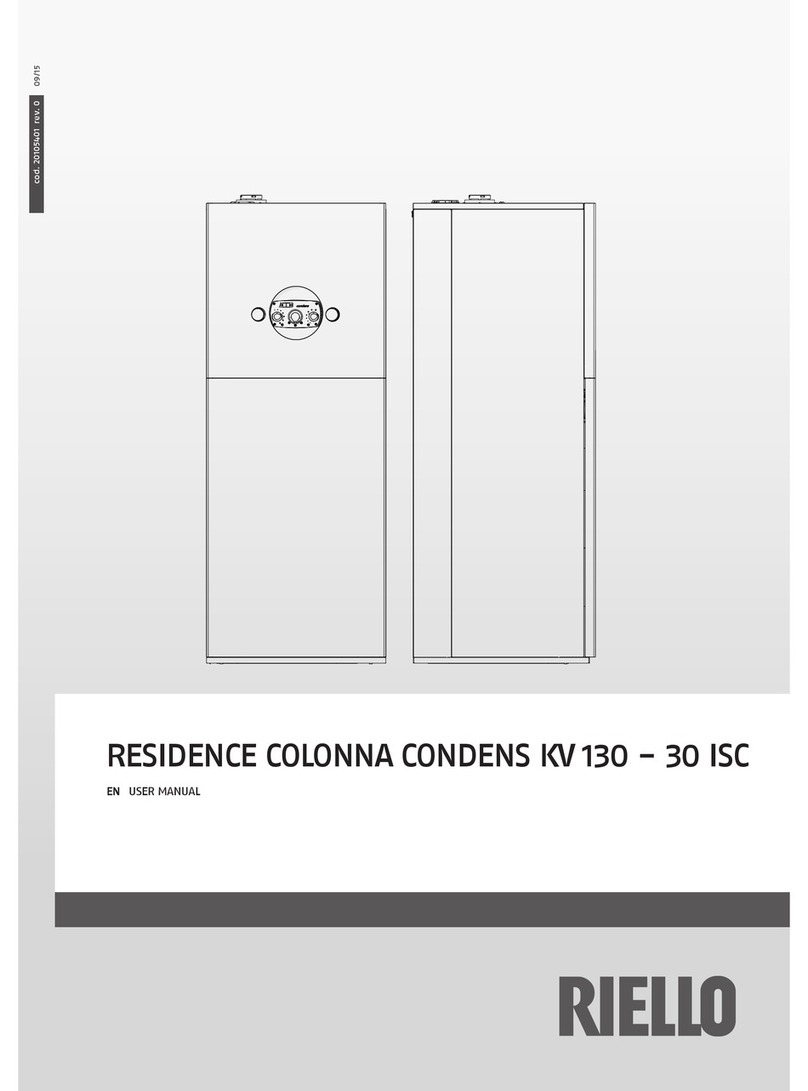

Riello Residence Colonna Condens KV 130-30 ISC User manual

Riello

Riello BSB 100 Operation and maintenance manual

Riello

Riello RTQ 109 Owner's manual

Riello

Riello BAG3 MIX BASIC Owner's manual

Riello

Riello MINI 11 User manual

Riello

Riello Family PRO 42 KIS User manual

Riello

Riello Family KIS Operation and installation manual

Riello

Riello FAMILY KI User manual

Riello

Riello Start 24 KI Operation and installation manual

Riello

Riello Caldariello 24 KIS C Operation and installation manual

Riello

Riello ALUDOMUS SOLAR KV/200 20 ISC SOLAR User manual

Riello

Riello TAU 55 UNIT Manual

Riello

Riello Condexa PRO NA 75 P Setup guide

Riello

Riello CSAL25 R 200 N REG User guide

Riello

Riello Residence Condens KIS n Operation and installation manual

Riello

Riello Condexa HPR 35 User guide

Riello

Riello Start Condens 25 IS Operation and installation manual

Riello

Riello TAU UNIT OIL 35 B Instruction Manual

Riello

Riello MINI 11 User manual

Popular Boiler manuals by other brands

Ferroli

Ferroli DOMIcompact F 30 D null

Vaillant

Vaillant uniSTOR VIH SW GB 500 BES operating instructions

Radijator

Radijator BIO max 23.1 instruction manual

Brunner

Brunner BSV 20 Instructions for use

Buderus

Buderus Logamax GB062-24 KDE H V2 Service manual

Potterton

Potterton 50e Installation and Servicing Manual

UTICA BOILERS

UTICA BOILERS TriFire Assembly instructions

Joannes

Joannes LADY Series Installation and maintenance manual

ECR International

ECR International UB90-125 Installation, operation & maintenance manual

Froling

Froling P4 Pellet 8 - 105 installation instructions

Froling

Froling FHG Turbo 3000 operating instructions

U.S. Boiler Company

U.S. Boiler Company K2 operating instructions