HEAT PUMP WATER HEATER COMPRESSOR CRITERIA FOR LONG LIFE SYSTEM

PAGE:5/23

1. SYSTEM DESIGN LIMITATIONS

1.1 Power source and Voltage

Voltage applied to hermetic terminal should be within the range mentioned

in this specification.

In the case of three phase, the phase imbalance should be within 3% among

the compressor terminals. The phase imbalance should be calculated

according to the follow formula.

(V)max-(V)mean

the phase imbalance= 100%

(V)mean

(V)max:Maximum voltage among the three terminals.(V)

(V)mean:average voltage among the three terminals.(V) 1.2 Operating

Temperatures and Pressures

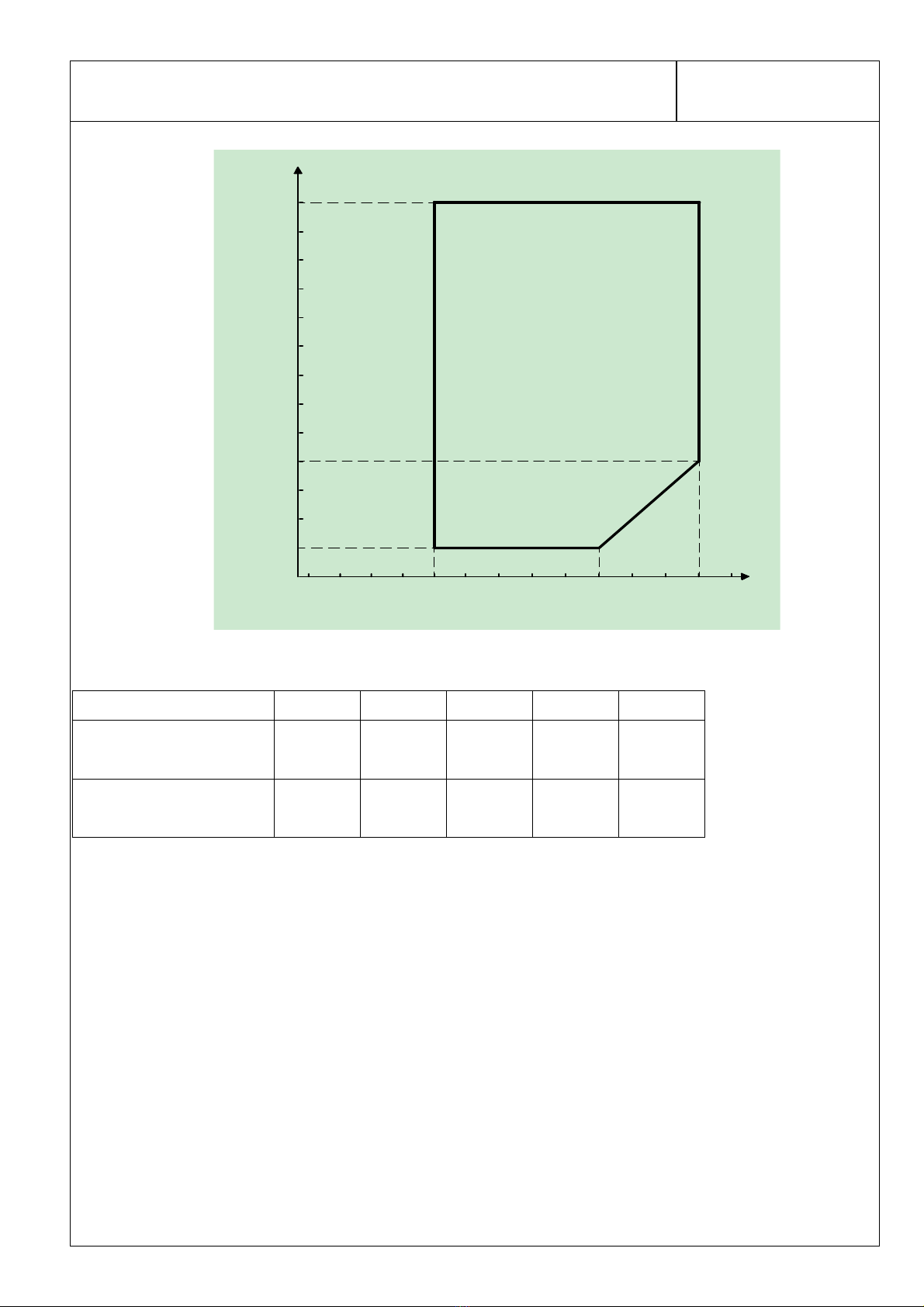

The operating temperatures and pressures of the compressor should be within

the range shown in the table 2 and graph 1.

1.3 Operating and Shut-off Period

The compressor should be operated continuously at least for 5 minutes after

being turned ON.

3 minutes shut-off time should be ensured at least until restarting.

1.4 Oil Back and height of the oil level

Oil should be returned continuously to the compressor and not kept in the

refrigeration system.

Oil level of compressor should be higher than 7.5 mm from the lubricating piece

fixed on the end of the crankshaft.

Compressor must not be started operated under a dual-layer separate status.

However, in case of foaming situation, the height of this foam does not mean

the height of the oil level.

If you do not keep the oil level, the oil shortage will occur, and influence the

reliability of compressor.

(Please check the oil level in the compressor with the sight glass we supply.)