5

Safety First

It is recommended that you thoroughly read and understand this manual before you attempt to service the

Thomas series of compressors to which this applies. PLEASENOTETHEFOLLOWINGCAUTIONS

AND WARNINGS FOR YOUR OWN SAFETY.

Caution

Toavoidpersonalinjuryand/or property damage, only authorized servicepersonnelshould

service this unit.

Warning

Toavoidtheriskofelectricalshock,personalinjury,ordeath,disconnectpowerbeforeservicingthis

unit.

Caution

To avoid personal injury, do not remove fan guards while unit is connected to power.

Caution

To avoid personal injury, especially to eyes and face, use eye and face protection when

servicing this unit.

Caution

To avoid personal injury, especially to eyes and face, never point the exhaust air flow at

yourself or other people in the area. Unit is capable of pressures of 100 psig.

Caution

Toavoiddamage,neverlubricateany component in your compressor. All moving parts are

permanently lubricated.

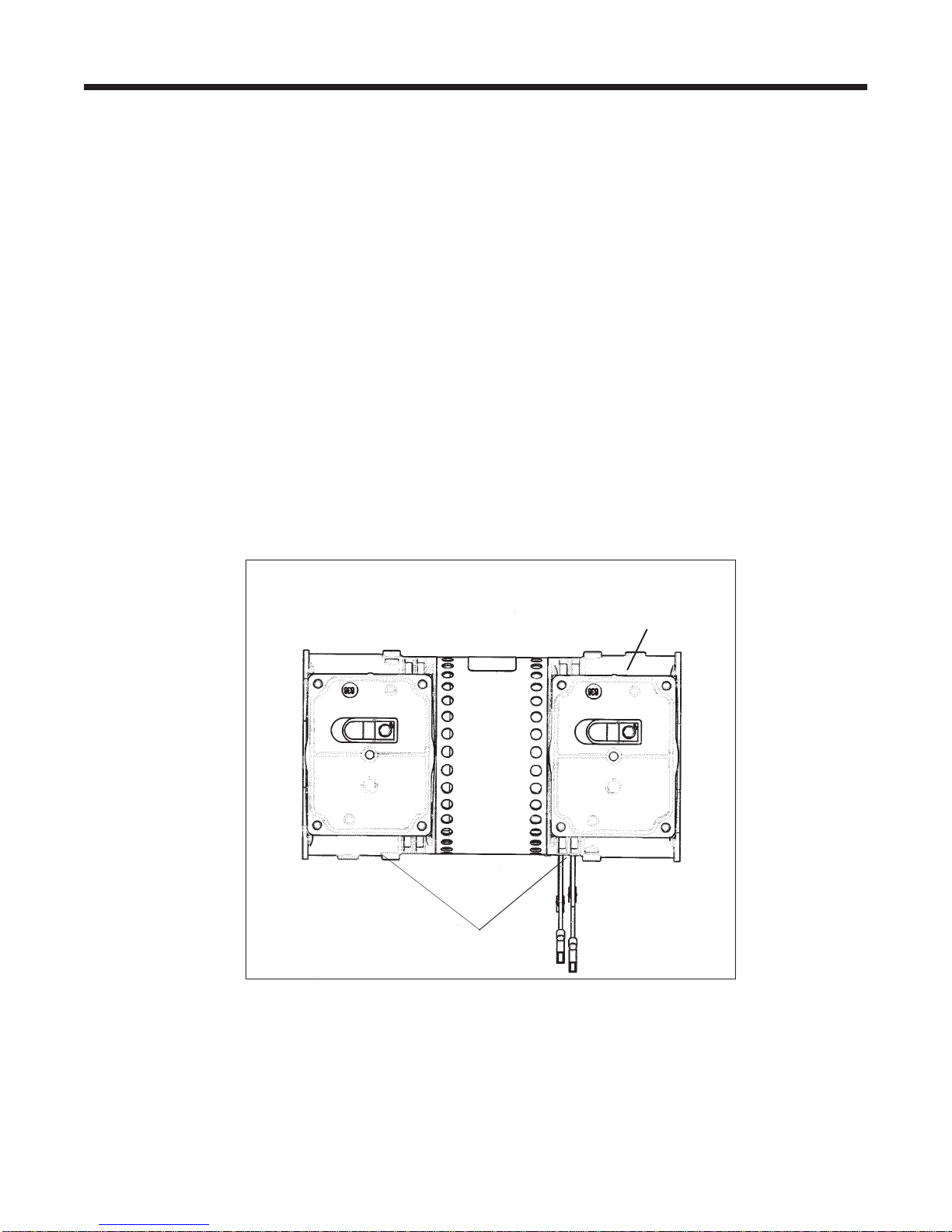

Caution

Toavoidpropertydamage or personal injury,alwaystryrotatingthe fan by HAND priorto

connectingtheunittothepowersource. Checkforsuctionattheairinletportbyplacingyour

finger over the port as you turn the fan. You should feel a slight suction with each rotation

ofthefan. Ifyoudontfeelsuction,orifyoufeelorhearathumpasyouturnthefan,DONOT

CONNECT THE UNIT TO A POWER SOURCE. Review the assembly procedure for

possible error.